Operation control method of high-voltage variable-frequency main coal flow intelligent conveying system

A technology of high-voltage frequency conversion and intelligent transportation, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of insufficient conveying speed, inconsistent coal volume, and insufficient response, so as to reduce operating costs, Good energy saving effect and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

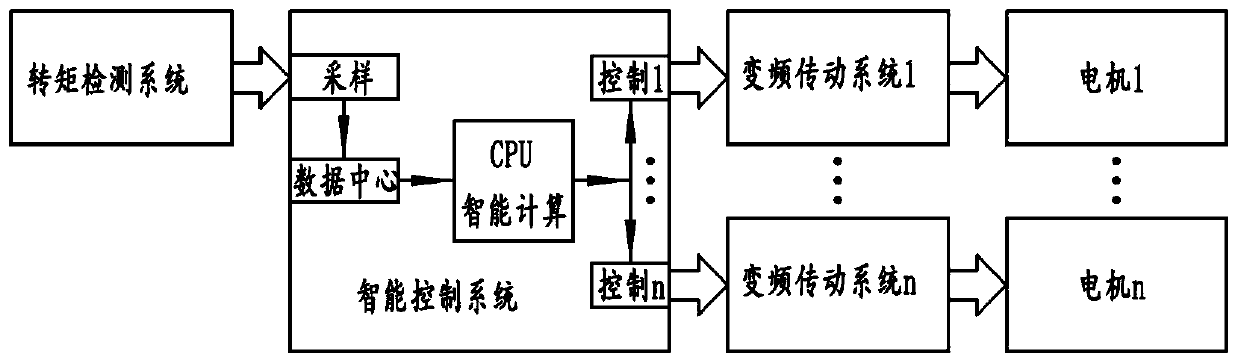

[0025] like figure 1 As shown, the mine high-voltage variable-frequency main coal flow conveying system in the embodiment of the present invention is driven by a 10kV (6kV) high-voltage frequency converter, and the mine high-voltage variable-frequency main coal flow conveying system includes a torque detection system, an intelligent control system, and a high-voltage variable-frequency transmission system.

[0026] The three systems of torque detection system, intelligent control system and high-voltage frequency conversion transmission system are all installed in the mine flameproof and intrinsically safe box. The main working principles are as follows:

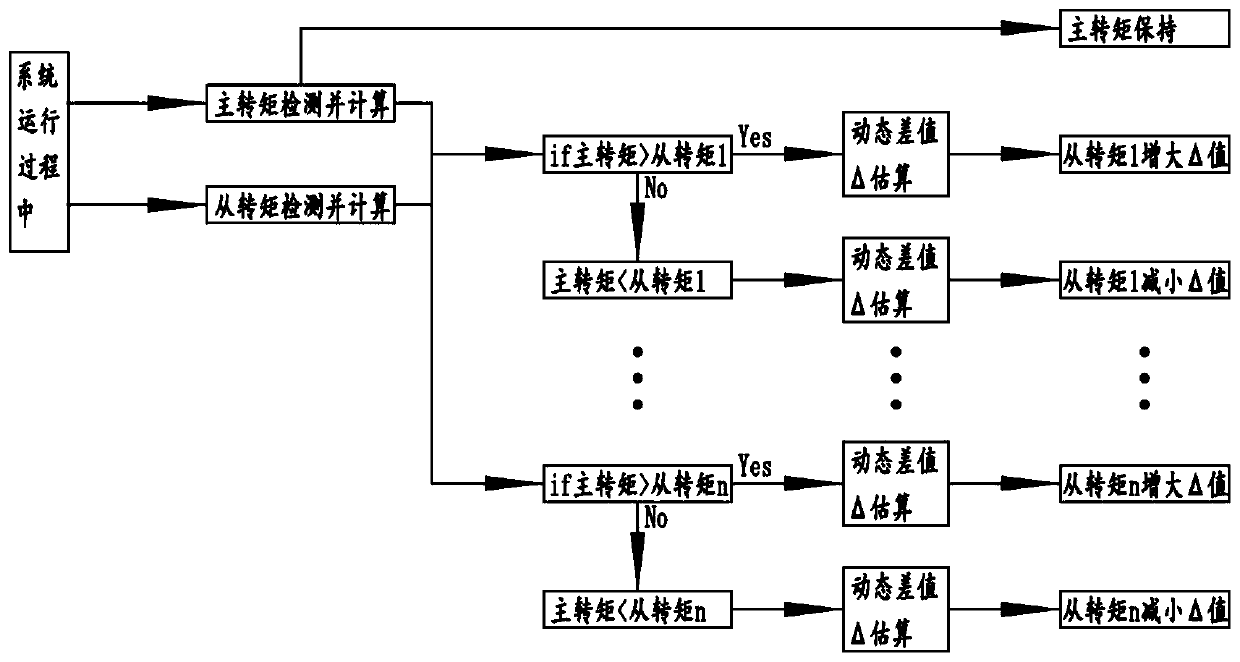

[0027] The output torque signal of the motor output by the torque detection system is sampled and then sent to the intelligent control system. The intelligent control system generates torque data that can be calculated from this signal, and uses this set of data to estimate and generate the amount of coal currently loaded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com