Water purification device and running method thereof

A technology of water purification device and operation method, which is applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc. Longevity and the effect of improving overall water quality safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

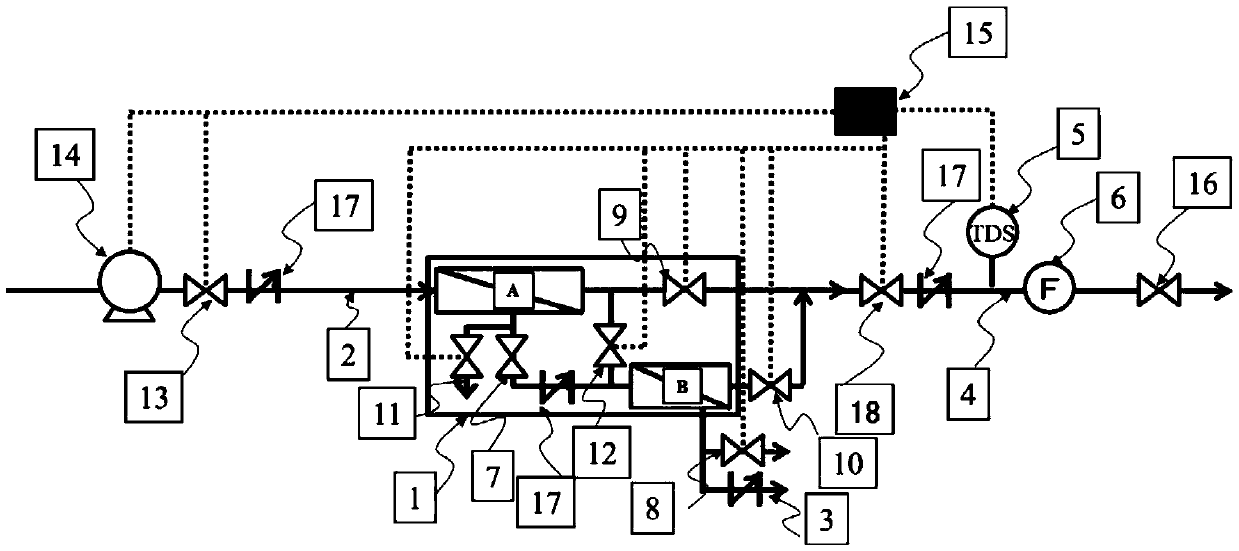

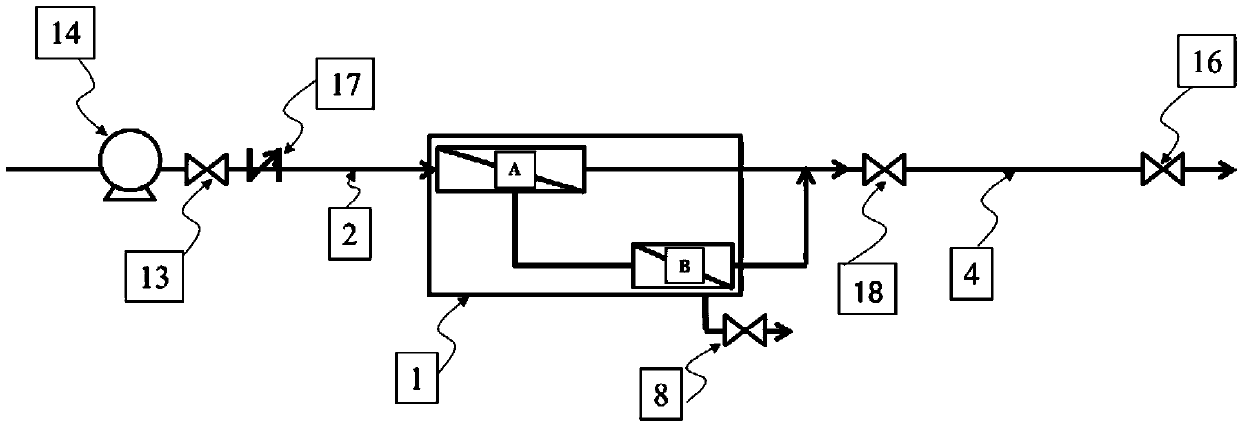

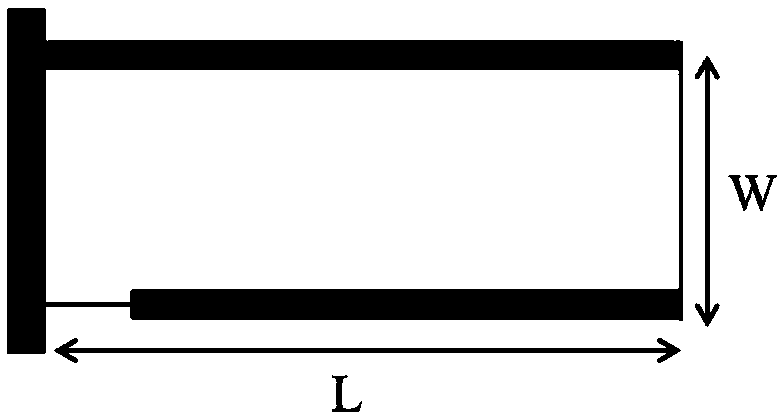

[0063] Such as figure 1The recovery rate of the membrane element of the water purification device shown is 75%, the feed water TDS is 300mg / L, the operating pressure is 0.55MPa, and the grid thickness of the supply side of the first semi-permeable membrane element and the second semi-permeable membrane element is 0.56 mm, the L / W ratio of the first semi-permeable membrane element is 3.0, the L / W ratio of the second semi-permeable membrane element is 5.0, the water production rate of the membrane is 0.9m / d (measured at 0.55MPa), the first semi-permeable membrane element The water production rate of the membrane element is 0.8m / d. The first semi-permeable membrane element is perpendicular to the two end faces of the perforated water collection pipe, including the raw water supply side and the concentrated water discharge side. The water production rate of the second semi-permeable membrane element is 0.7m / d. d (Due to the pressure loss of the rolled membrane element, the water p...

Embodiment 2

[0065] Such as figure 1 The recovery rate of the membrane element of the water purification device shown is 75%, the feed water TDS is 300mg / L, the operating pressure is 0.55MPa, and the grid thickness of the supply side of the first semi-permeable membrane element and the second semi-permeable membrane element is 0.56 mm, the L / W ratio of the first semi-permeable membrane element is 3.0, the L / W ratio of the second semi-permeable membrane element is 5.0, the water production rate of the membrane is 0.9m / d (measured at 0.55MPa), the first semi-permeable membrane element The water production rate of the membrane element is 0.8m / d. The first semi-permeable membrane element is perpendicular to the two end faces of the perforated water collection pipe, including the raw water supply side and the concentrated water discharge side. The water production rate of the second semi-permeable membrane element is 0.7m / d. d (Due to the pressure loss of the rolled membrane element, the water ...

Embodiment 3

[0067] Such as figure 1 The recovery rate of the membrane element of the water purification device shown is 75%, the feed water TDS is 300mg / L, the operating pressure is 0.55MPa, and the grid thickness of the supply side of the first semi-permeable membrane element and the second semi-permeable membrane element is 0.56 mm, the L / W ratio of the first semi-permeable membrane element is 3.0, the L / W ratio of the second semi-permeable membrane element is 5.0, the water production rate of the membrane is 0.9m / d (measured at 0.55MPa), the first semi-permeable membrane element The water production rate of the membrane element is 0.8m / d. The first semi-permeable membrane element is perpendicular to the two end faces of the perforated water collection pipe, including the raw water supply side and the concentrated water discharge side. The water production rate of the second semi-permeable membrane element is 0.7m / d. d (Due to the pressure loss of the rolled membrane element, the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com