Garment processing equipment

A processing equipment and clothing technology, which is applied in the field of clothing processing, can solve the problems of large space occupation and inability to quickly recycle fabrics, and achieve the effects of small space occupation, convenient operation and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

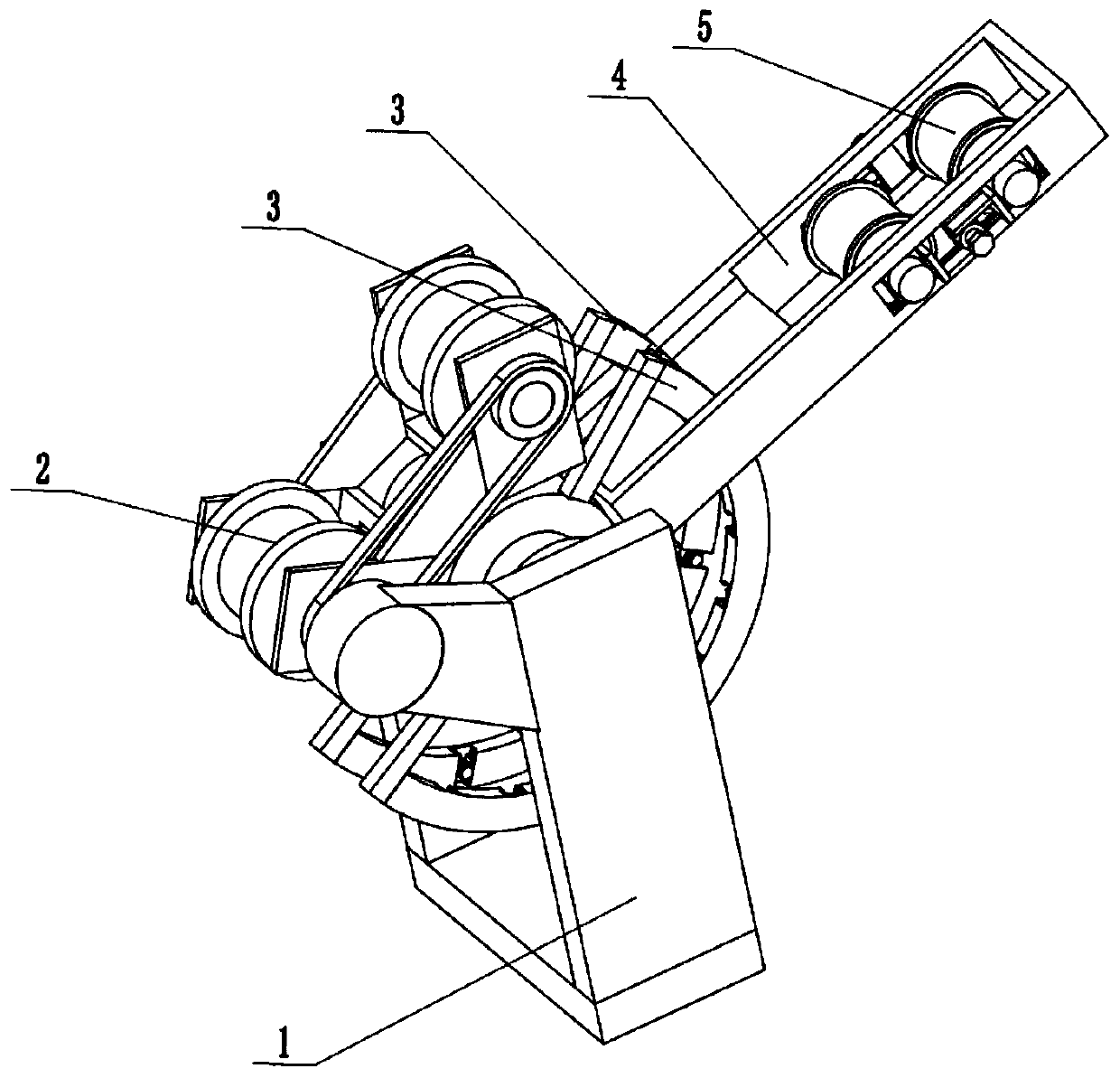

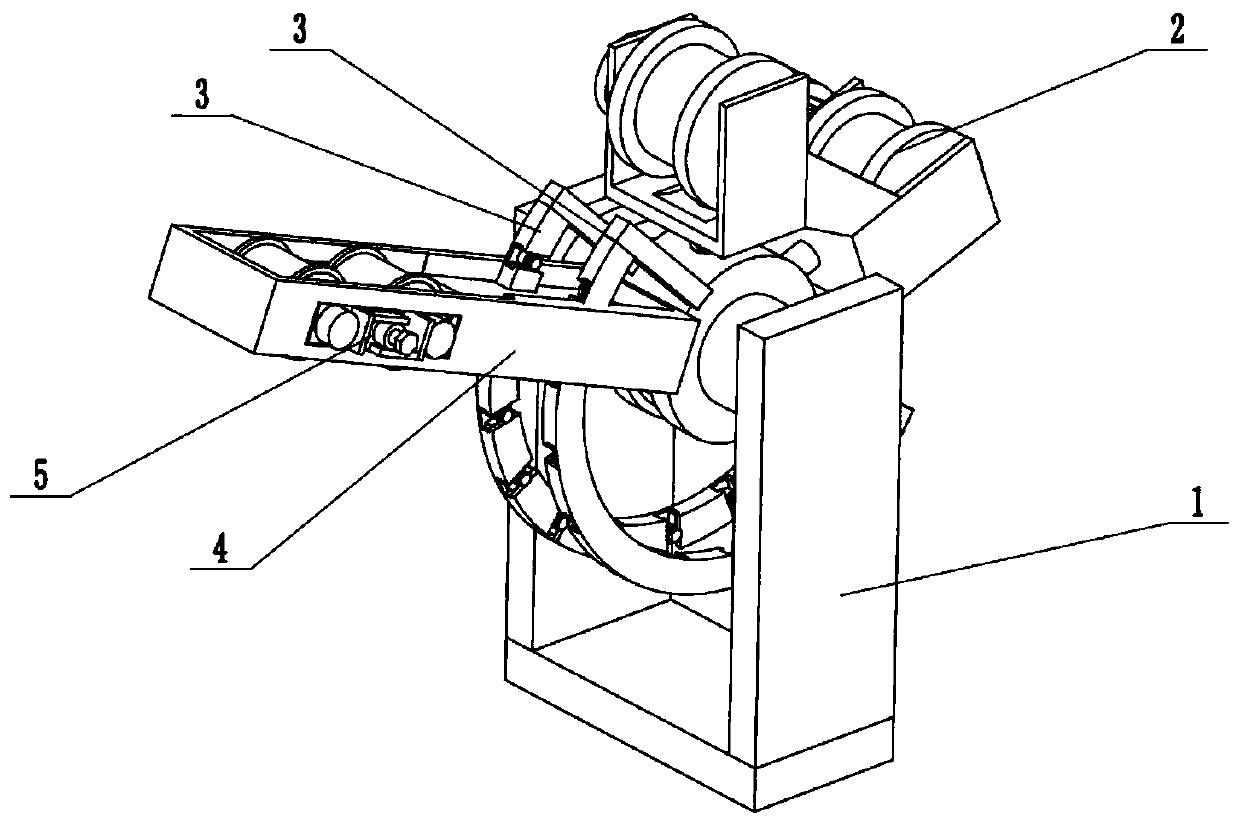

[0029] Such as Figure 1 to Figure 10 As shown, a garment processing equipment includes a fixed base 1, a retractable synchronous driver 2, two retractable distance regulators 3, a stretch adjustment seat 4 and a stretch regulator 5, and the retractable synchronous driver 2 is fixed Connected to the fixed base 1, the two retractable distance regulators 3 are fixedly connected in the fixed base 1, the stretch adjusting seat 4 is slidably connected to the fixed base 1, and the two ends of the stretch adjuster 5 are slidably connected to the stretching On the adjustment seat 4. Place the fabric roller and take-up roller that need to be stretched on the release and take-up synchronous drive 2, so that the released fabric is connected to the take-up roller through the stretch regulator 5 to form the connection of the fabric, and the fabric is tightened by manually rotating the take-up roller The pattern needs to stretch the material of the cloth, adjust the distance between the st...

specific Embodiment approach 2

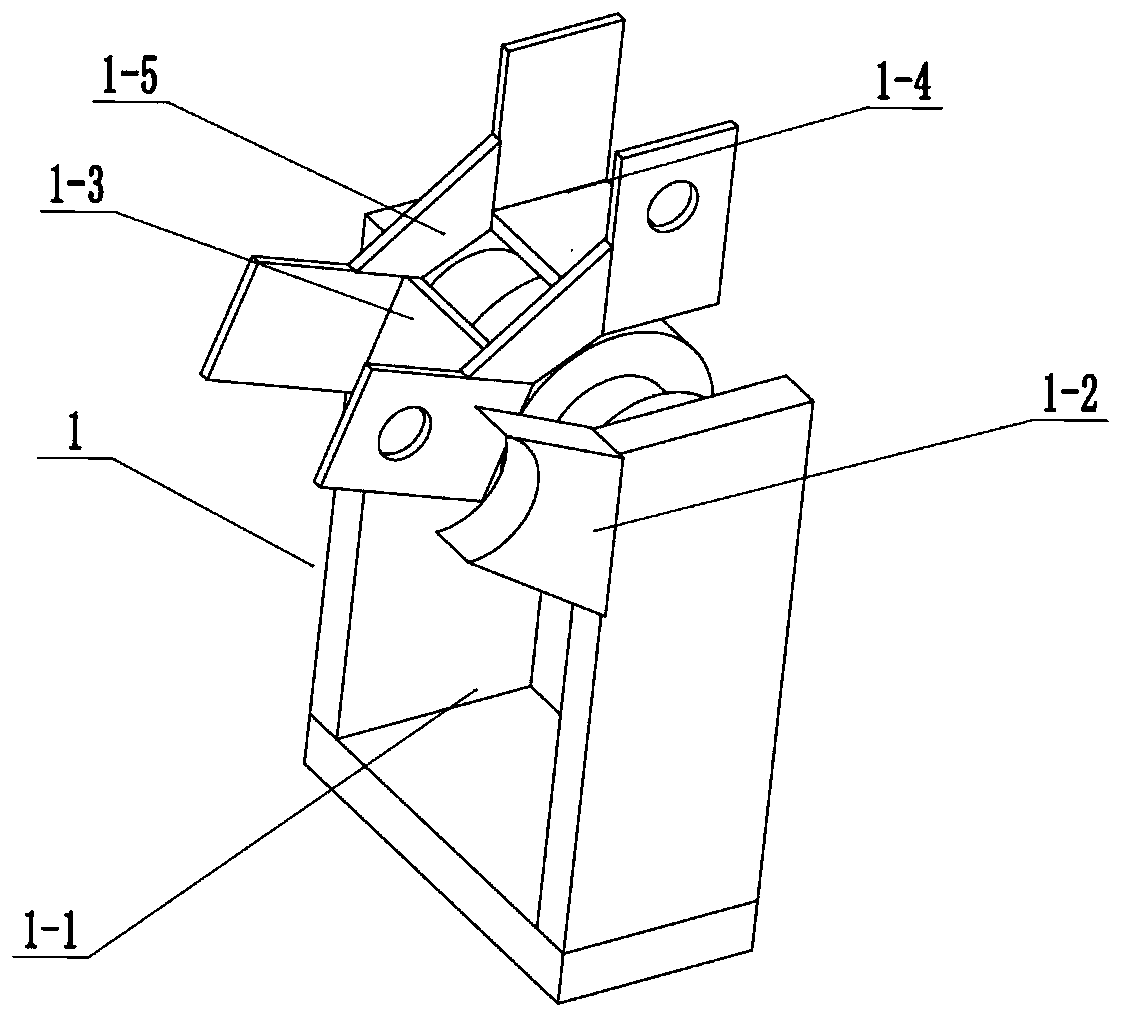

[0031] Such as Figure 1 to Figure 10As shown, this embodiment further explains Embodiment 1. The fixed base 1 includes a fixed bottom frame 1-1, a motor fixing seat 1-2, a cloth releasing roller driving seat 1-3, and a cloth receiving roller driving seat 1- 4. Two connecting plates 1-5, two fixed bottom shafts 1-6, sliding and fixed round table 1-7, T-shaped sliding groove 1-8 and fixed shaft 1-9, motor fixing seat 1-2 is fixedly connected to the fixed On the bottom frame 1-1, the bottom ends of the cloth releasing roller driving seat 1-3 and the cloth receiving roller driving seat 1-4 are respectively fixedly connected to the sliding fixed round table 1-7 through two fixed bottom shafts 1-6, The roller driving seat 1-3 and the cloth receiving roller driving seat 1-4 are fixedly connected through two connecting plates 1-5, and the sliding and fixing round table 1-7 is provided with a T-shaped sliding groove 1-8, and the sliding and fixing round table 1 -7 is fixedly connecte...

specific Embodiment approach 3

[0033] Such as Figure 1 to Figure 10 As shown, this embodiment will further explain Embodiment 2. The synchronous drive 2 includes a servo motor 2-1, a cloth releasing roller drive shaft 2-2, a cloth releasing roller 2-3, and a main drive pulley 2- 4. From the driving pulley 2-5, the cloth receiving roller drive shaft 2-6 and the cloth receiving roller 2-7, the servo motor 2-1 is fixedly connected to the motor fixing seat 1-2, and the cloth releasing roller driving shaft 2-2 passes through The coupling is connected to the transmission shaft of the servo motor 2-1, the drive shaft 2-2 of the cloth release roller is connected in rotation to the drive seat 1-3 of the cloth release roller, and the cloth release roller 2-3 is fixedly connected to the drive shaft of the cloth release roller by bolts 2-2, the main drive pulley 2-4 is fixedly connected to the transmission shaft of the servo motor 2-1, the main drive pulley 2-4 is connected to the slave drive pulley 2-5 through a sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com