Cable working well

A technology for cable wells and cable pipes, which is applied in cable installation, cable installation in cable rooms, and cable installation in underground pipelines. It can solve problems such as uneven settlement and low investment, and achieve convenient construction and low investment. Less, solve the effect of uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

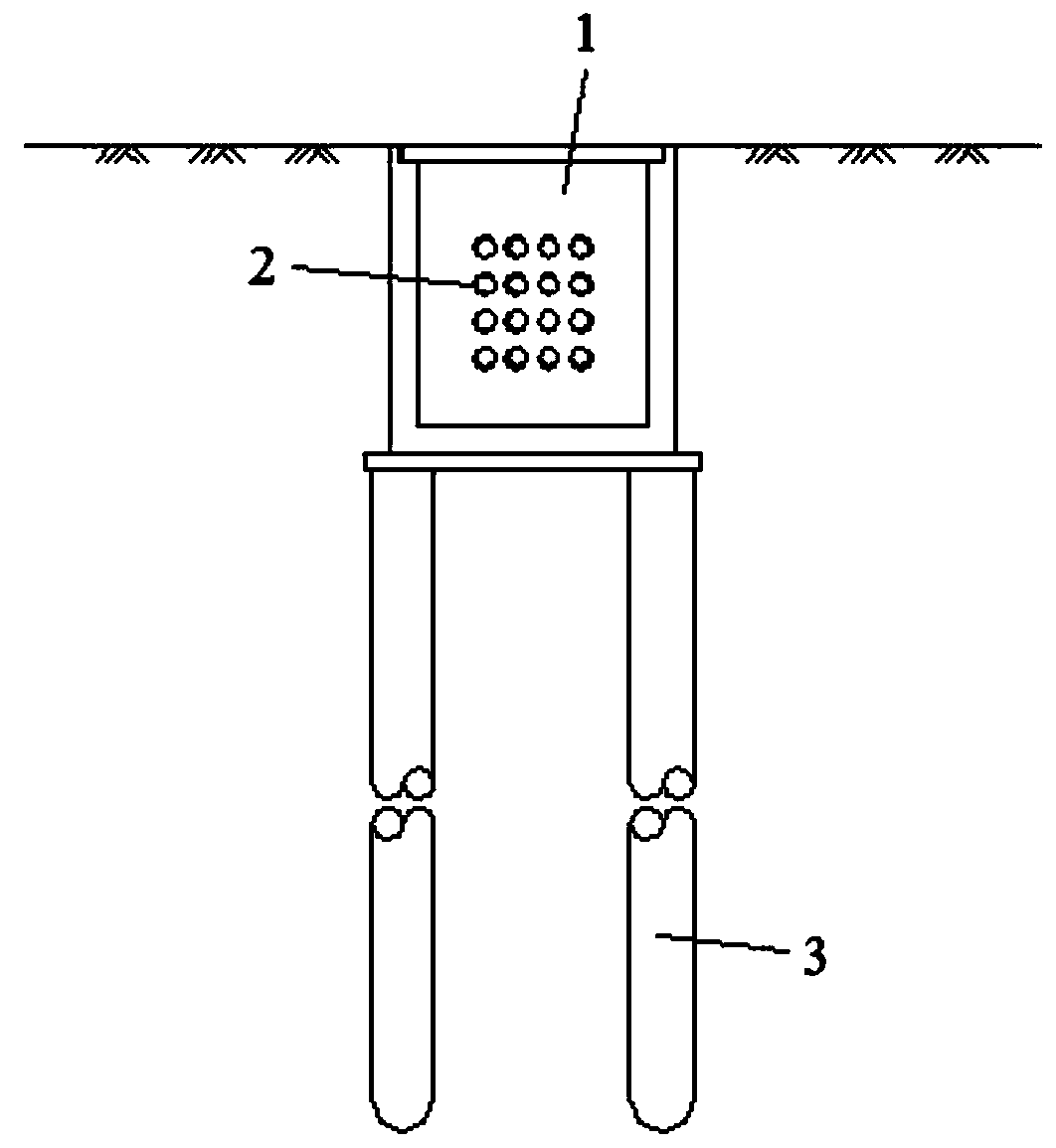

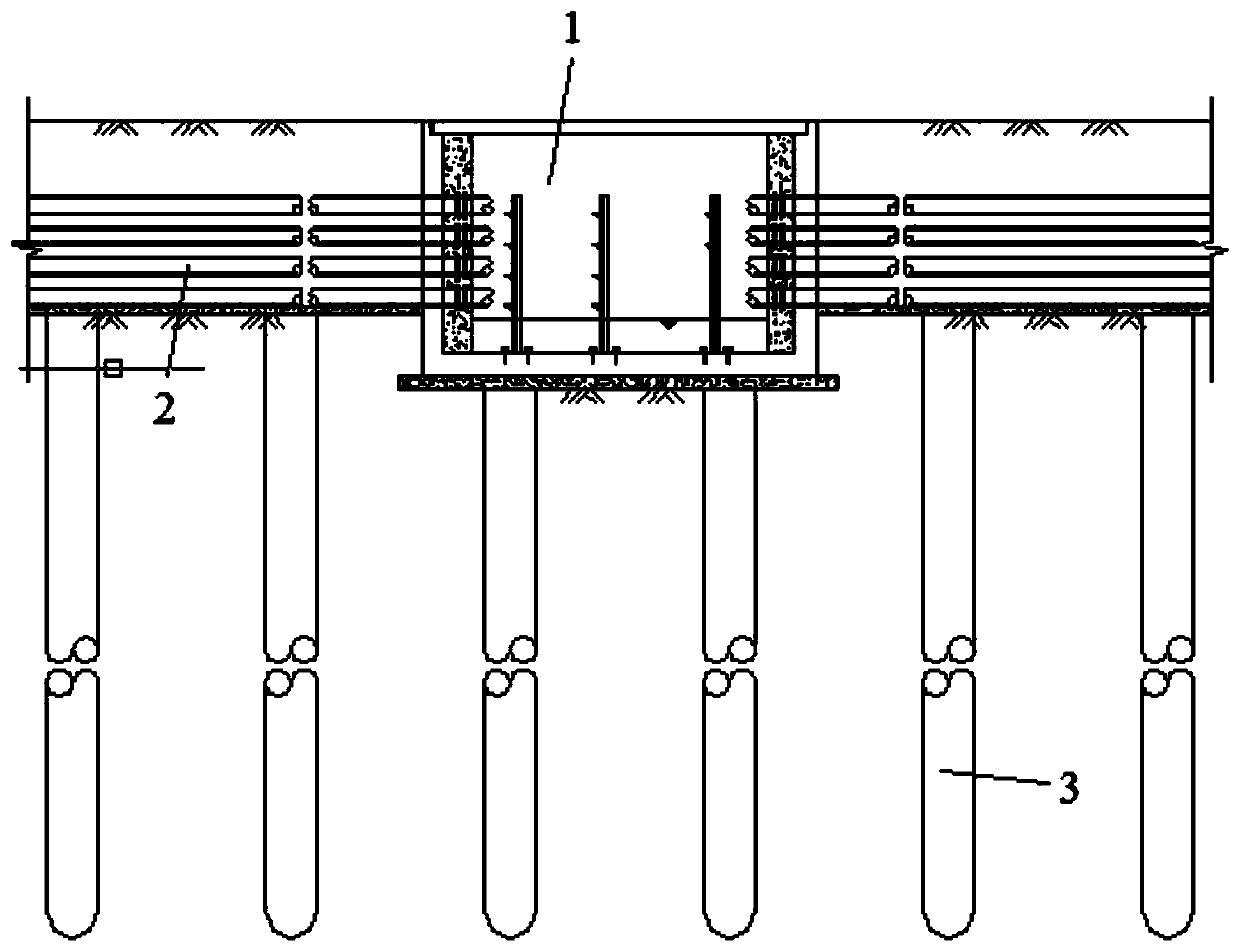

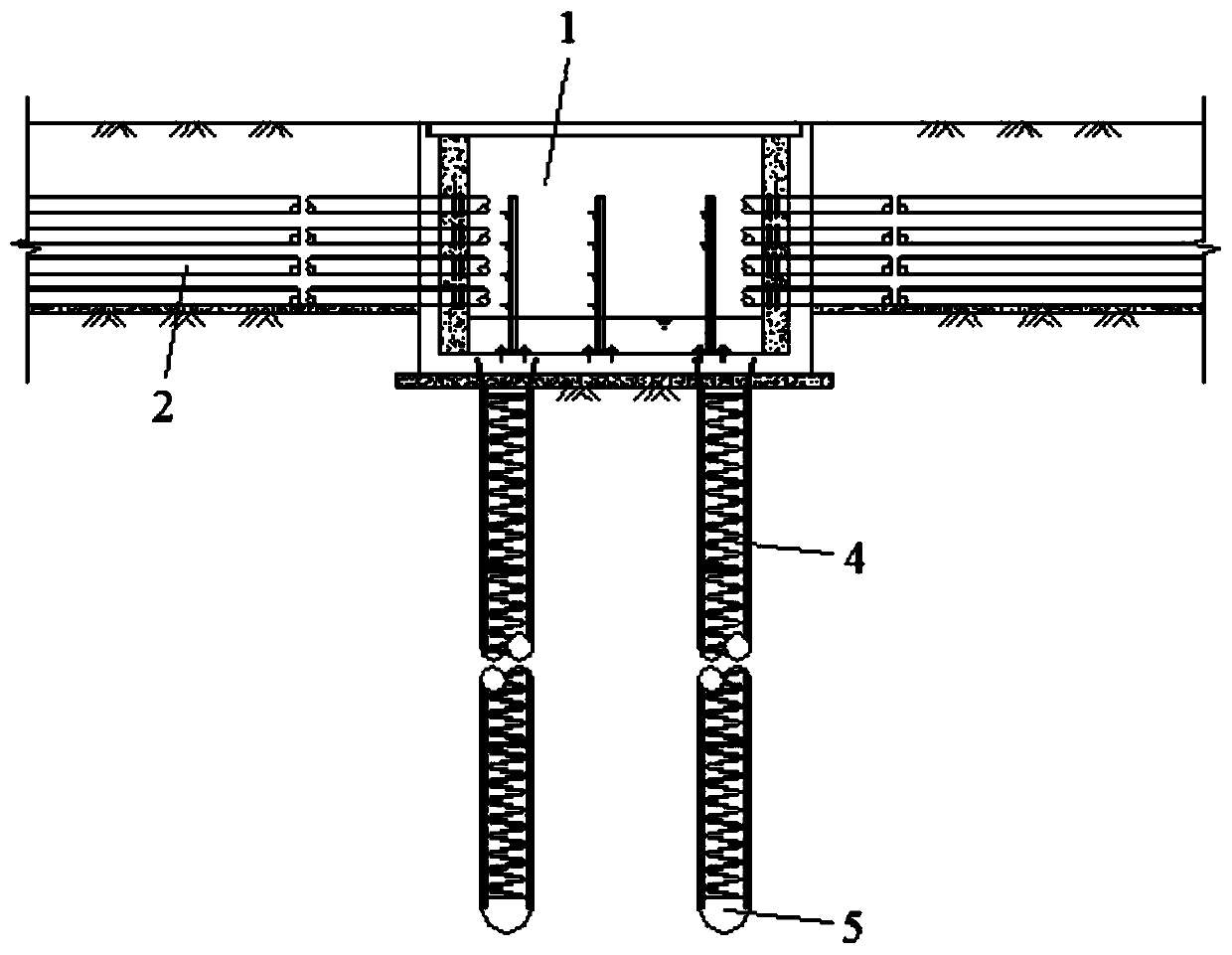

[0030] Embodiment one: as attached Figure 5 to attach Figure 7 As shown, a cable well includes a bottom plate 6 , a side wall 7 and a cover plate 8 enclosing the space in the well, and also includes a cushion 9 and a cable support 10 . The cable well includes four side walls 7, which are respectively a pair of opposite connecting side walls 7 and a pair of opposite supporting side walls 7, and the connecting side walls 7 are used for connecting cable pipes. The cushion layer 9 is disposed under the bottom plate 6 .

[0031] The bottom plate 6 has an overhanging portion 11 protruding from the outer edge of the side wall 7 along the extending direction of the cable duct, so that the bottom plate 6 constitutes an extended bottom plate 6 . The cable conduit also includes a balance portion 12 arranged on the outstretched portion 11 of the bottom plate 6 and used for balancing stress and supporting the cable conduit. The balance part 12 is formed by flakes or plain concrete, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com