Method and device for detecting laser spot scanning accuracy of laser processing equipment

A laser processing and laser spot technology, which is used in measuring devices, optical instrument testing, and machine/structural component testing. Solve problems such as the difficulty of the problem, and achieve the effect of enriching the detection methods of laser precision processing, intuitive and accurate measurement methods, and simplifying the proofing detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

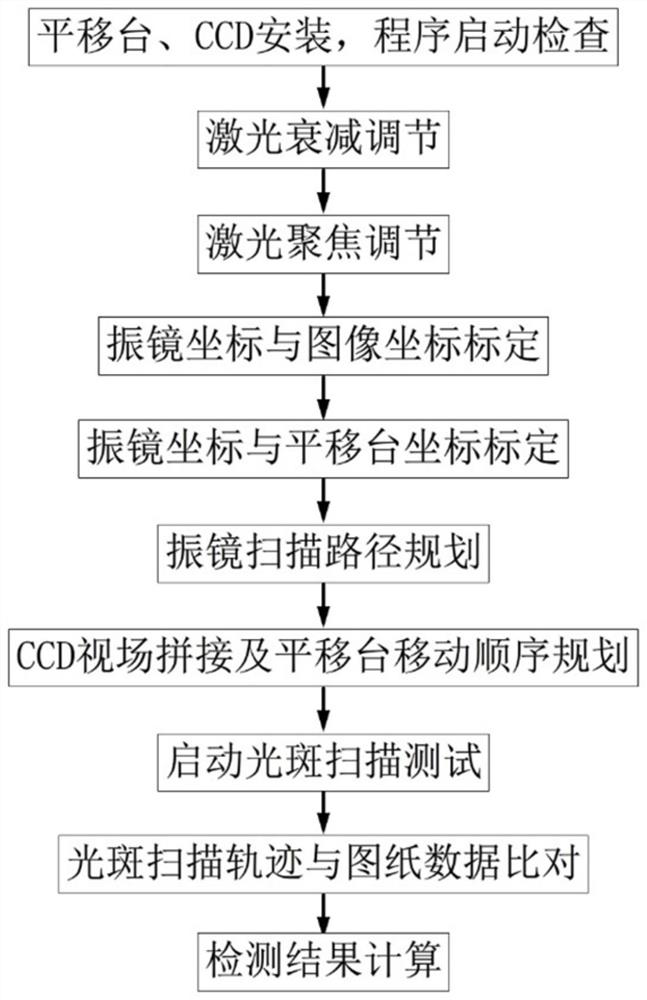

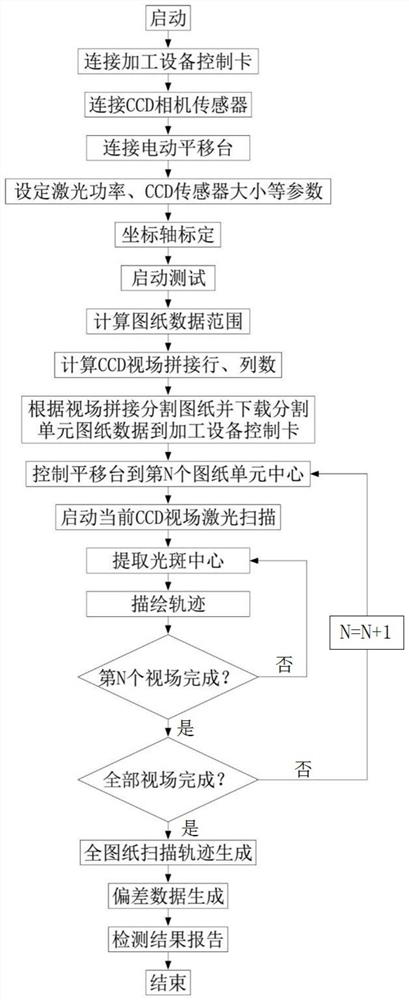

[0058] Such as figure 1 and figure 2 As shown, the preferred embodiment of the laser spot scanning accuracy detection method of the laser processing equipment includes the following steps:

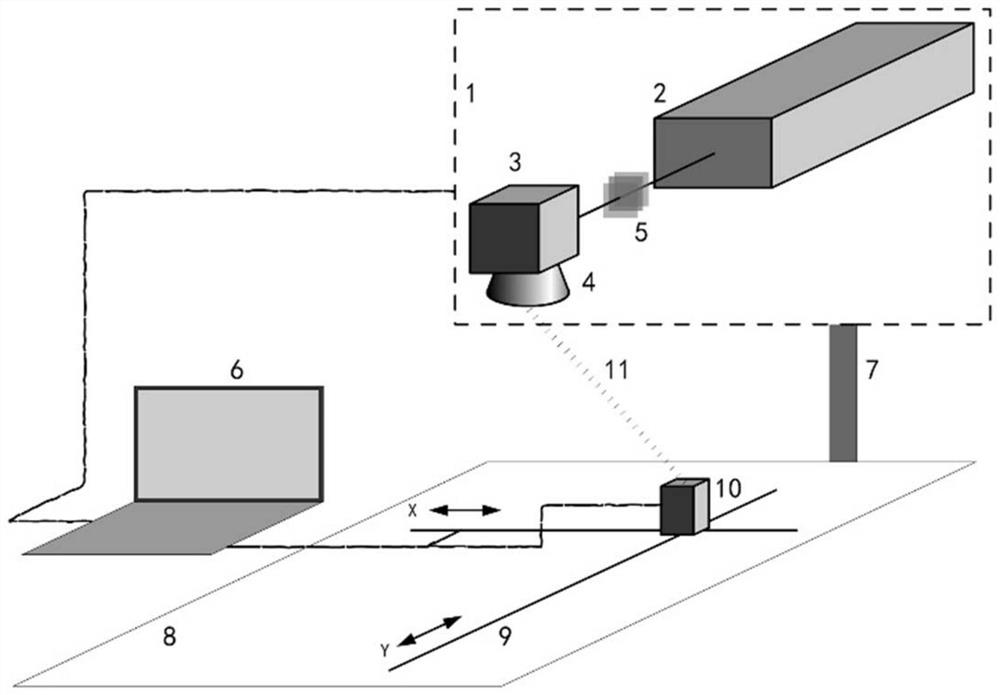

[0059] In step 1, the translation stage 9 and the CCD camera 10 are installed, and the program is started for inspection.

[0060] A high-precision two-dimensional electric translation platform 9 is set on the working surface 8 of the laser processing equipment. The translation platform 9 can move along the horizontal and vertical directions of the working surface 8, and the center of the moving range of the translation platform 9 is aligned with the center of the processing area. ; Install a lens-removing CCD camera 10 on the translation stage 9; wherein, the photosensitive surface of the CCD camera 10 is aimed at the laser beam 11 output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com