A metal point source for evaporation equipment and its application

A metal point and metal technology, applied in the field of metal point sources, can solve the problems of inability to guarantee the uniformity of heating and the inability to meet the requirements of fine control of evaporation, and achieve the effects of stable heat conduction and dissipation, reducing heat dissipation and heating uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

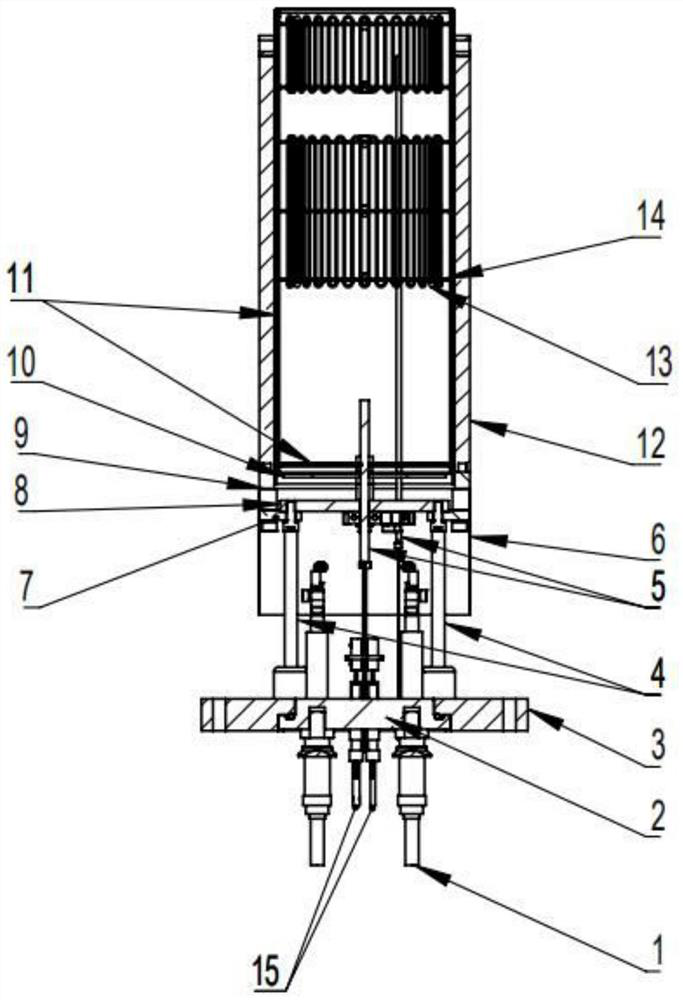

[0057] This embodiment provides a metal point source for evaporation equipment, including a connection base 2, a connection flange 3, an external electrode 1, a thermocouple 5, a cooling water pipe 4, a metal heater, a heat preservation plate 11 and a cooling water jacket 12;

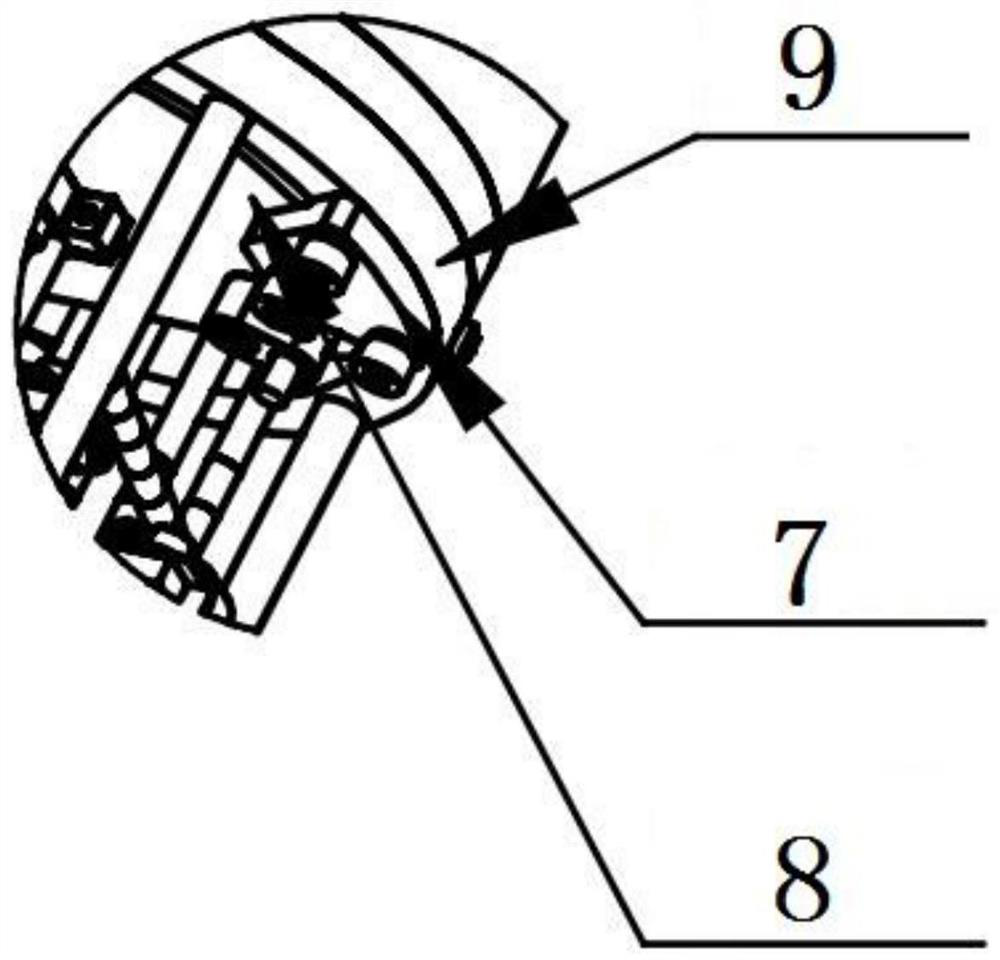

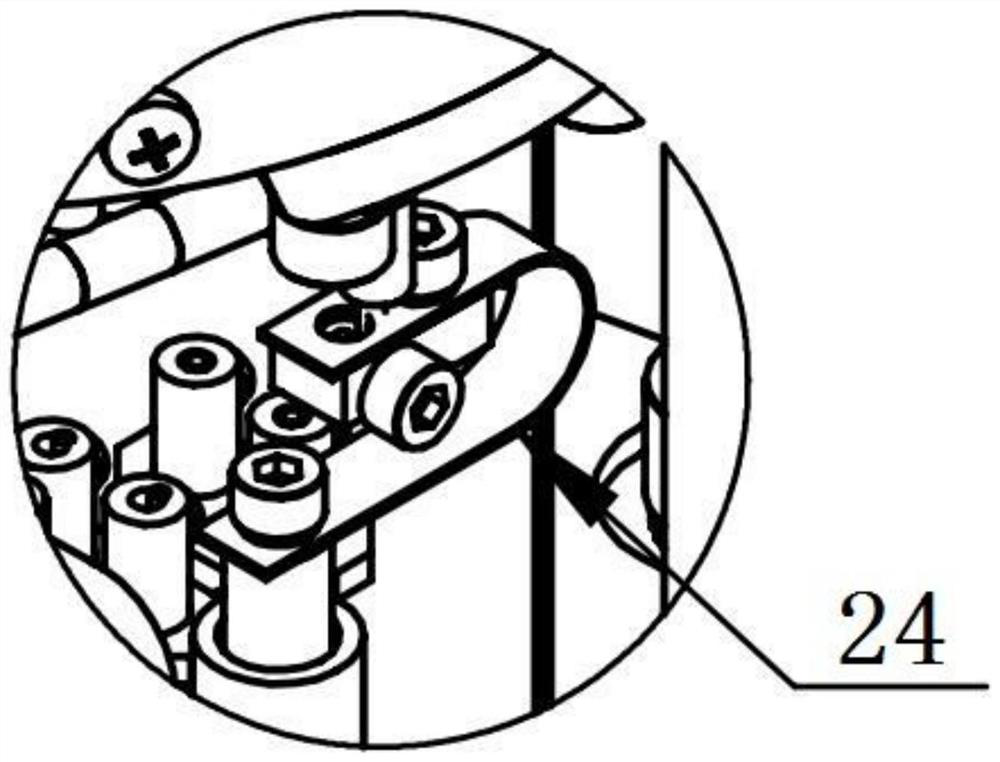

[0058] The metal heater is connected to the inner wall of the insulation board 11, and the insulation board 11 is provided with a cooling water jacket 12, and the bottom of the cooling water jacket 12 is connected with a bottom ring 9, and the large support plate 8 is located in the bottom ring 9 and passes through the small support at the bottom of the bottom ring 9 The board 7 is supported and connected, and a base plate 10 is arranged above the large supporting plate 8, and the base plate 10 is supported and connected to the heat preservation board 11;

[0059] The external electrode 1 and the thermocouple 5 run through the connection base 2 respectively, and the connection base 2 is installed on the...

Embodiment 2

[0074] A kind of metal point source that is used on the vapor deposition equipment, the structure is as described in embodiment 1, and its difference is: be provided with 3 groups of thermocouple joints 15 on the connection base 2, as Figure 13 shown. Set up 2 more thermocouple connectors for backup to avoid failure and failure to work normally.

Embodiment 3

[0076] A metal point source used on evaporation equipment, the structure is as described in Embodiment 1, the difference is that: the bottom of the bottom ring 9 is connected with a shield 6, and the shield 6 is connected with the bottom ring 9 by screws. Such as figure 1 As shown, the shield plays the role of isolation protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com