A coal blending and coking method for regulating the proportion of strongly sticky coal

A technology for blending coal for coking and sticking coal, applied in coke ovens, petroleum industry, etc., can solve problems such as inability to characterize quality characteristics alone, not being valued by production, and fluctuating coke quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

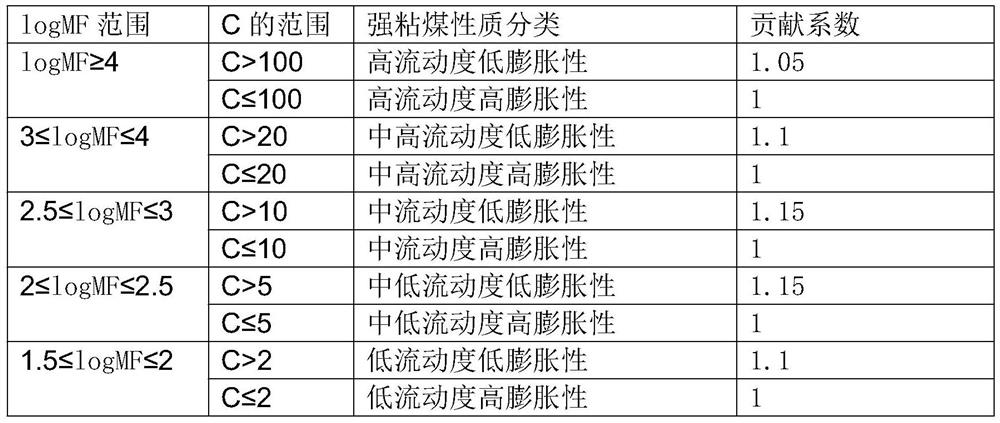

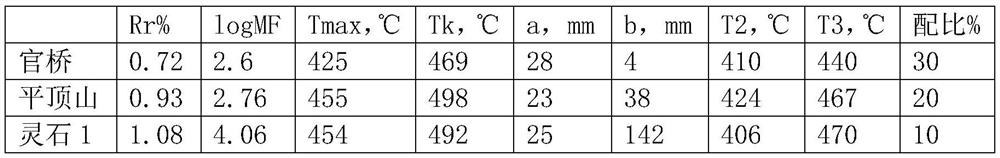

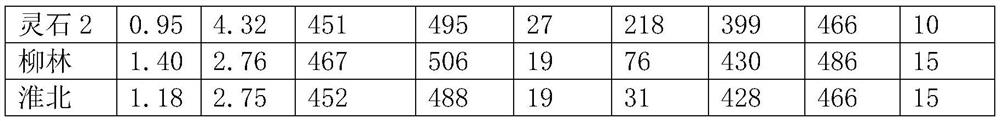

[0031] The coal blending plan of a coking production enterprise before adjustment is: strong caking coal from six mining points from Guanqiao mining point, Pingdingshan mining point, Lingshi mining point 1, Lingshi mining point 2, Liulin mining point, and Huaibei mining point Composition according to the following ratio:

[0032] According to the industry standard MT / T 1015-2006, measure the Gibbs maximum fluidity MF, Gibbs solidification temperature Tk, and Gibbs maximum fluidity temperature Tmax of each strong caking coal;

[0033] According to the national standard GB 5450-85, the maximum shrinkage distance a, the maximum expansion distance b, the stop expansion temperature T3 and the maximum shrinkage temperature T2 of the Aurora expansion degree of various coals were measured.

[0034]

[0035]

[0036] Among them, the Rr of the coal at Guanqiao mining site is 0.72%, which belongs to non-strongly caking coal, and the coal of the other 5 mining sites is defined as co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com