Automobile inspection tool rotating device

A technology of rotating device and inspection tool, applied in the direction of manufacturing tools, program control manipulators, manipulators, etc., can solve the problems of inability to meet production needs, low efficiency of inspection tool processing, and inability to process workpieces, etc. The effect of high practicability and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

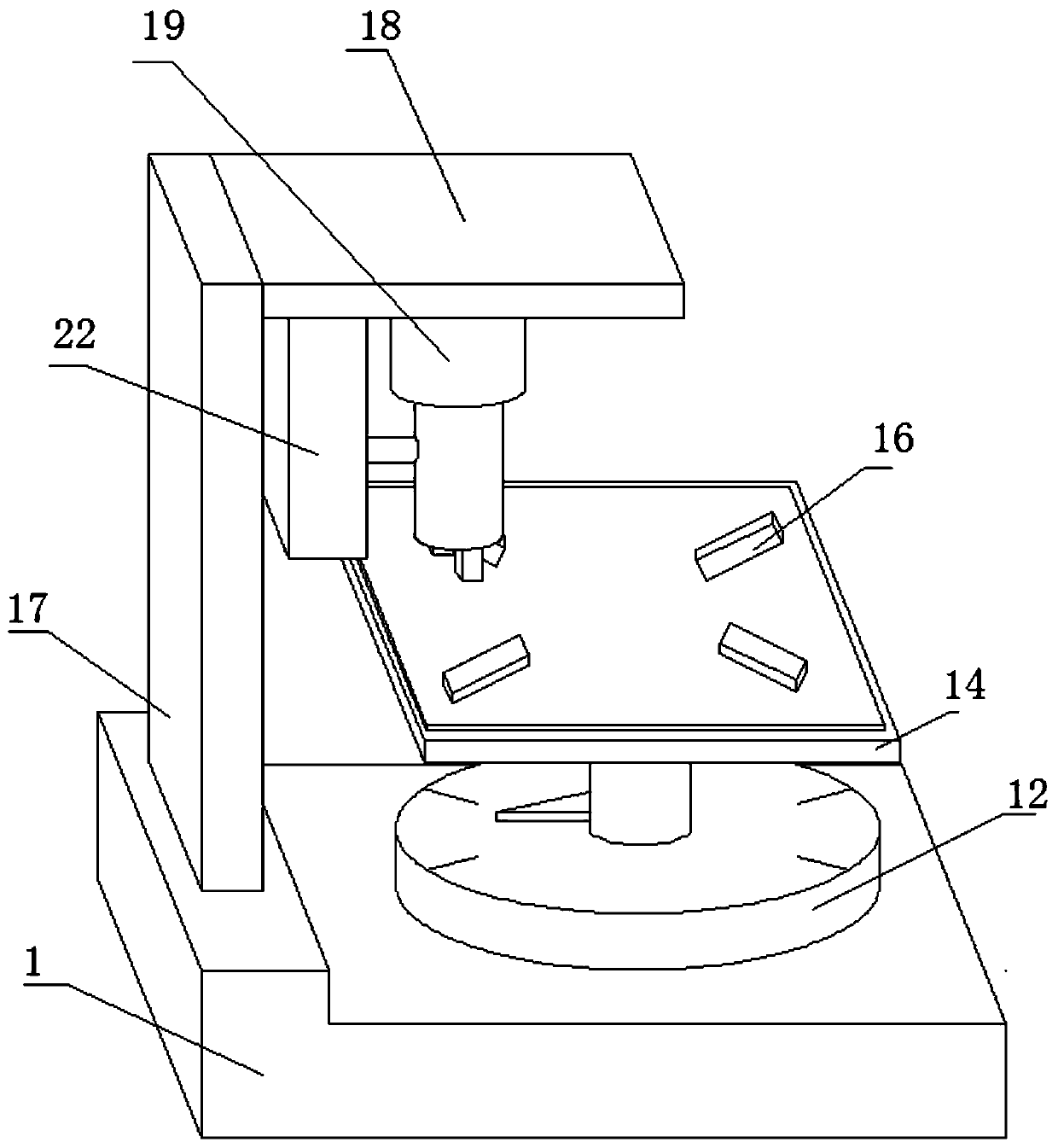

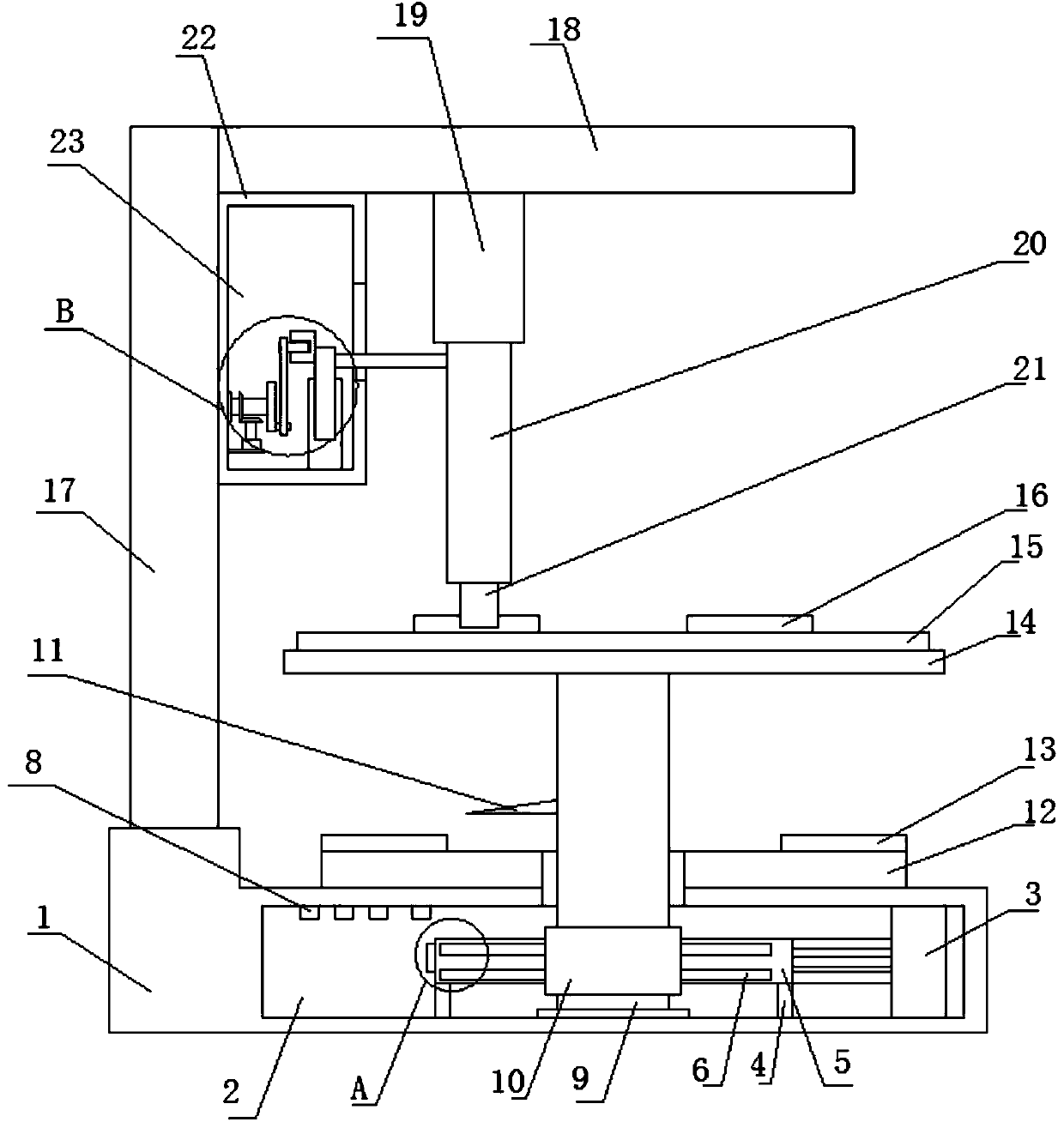

[0024] refer to Figure 1-5 In this embodiment, a car inspection tool rotation device is proposed, including a base 1, a chamber 2 is provided on the base 1, a vertical shaft 9 is installed on the bottom inner wall of the chamber 2, and the top of the vertical shaft 9 runs through the chamber 2 and extends to the top of the base 1, and the top of the vertical shaft 9 is rotatably connected to the top inner wall of the chamber 2, and the outer side of the vertical shaft 9 is fixedly installed with a pointing block 11, and the vertical shaft 9 is connected with a rotating assembly , the top of the vertical shaft 9 is fixedly installed with a placement tray 14, and the top of the placement tray 14 is placed with a workpiece 15, and the top of the workpiece 15 is provided with a plurality of processing positions 16 symmetrically arranged at the center point, and the top side of the base 1 is fixed and installed There is a vertical plate 17, and one side of the vertical plate 17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com