Welding line double-clamp switching control method

A control method and double fixture technology, applied in the direction of program control, general control system, electrical program control, etc., can solve the problems of not having large-scale promotion and use, and achieve the effect of meeting the switching drive requirements, avoiding logic writing, and achieving standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

[0034] The present invention realizes the function of the welding line double fixture switching control system through hardware design and software programming, and through the standardized development of software and hardware. The specific content is as follows:

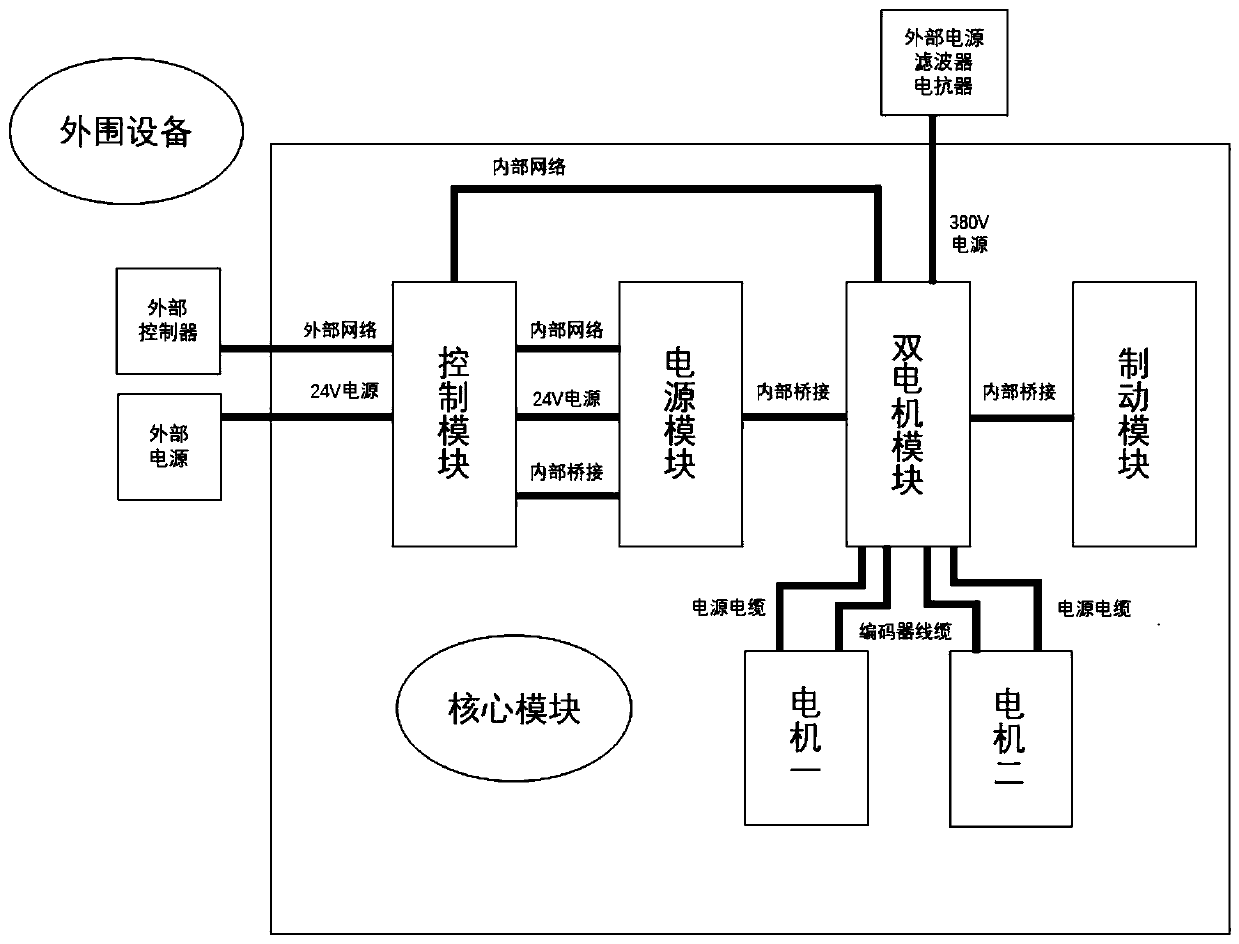

[0035] 1. Hardware modularization: Based on the related hardware of Siemens SINAMICS S120 drive system, it includes five core components including control module, power module, dual motor control module, braking module and motor. refer to figure 1 , the core module is the hardware composition of hardware standardization. The functions of each core module are as follows:

[0036] 1. Control module: the brain of the drive system, responsible for controlling and coordinating all modules in the entire system.

[0037] 2. Power module: the rectifier module, which rectifies the three-phase AC power into DC power and su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com