Dust removal device for floor mat production

A technology of dust removal device and floor mat, which is applied in the direction of dust removal, application, household appliances, etc., and can solve the problems of poor dust removal effect of scraper floor mat and no cleaning brushes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

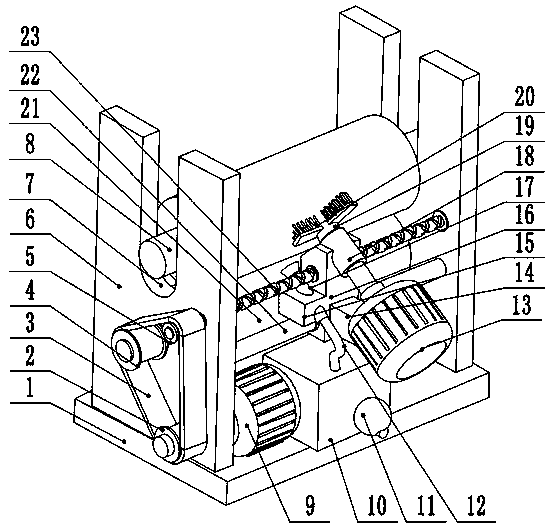

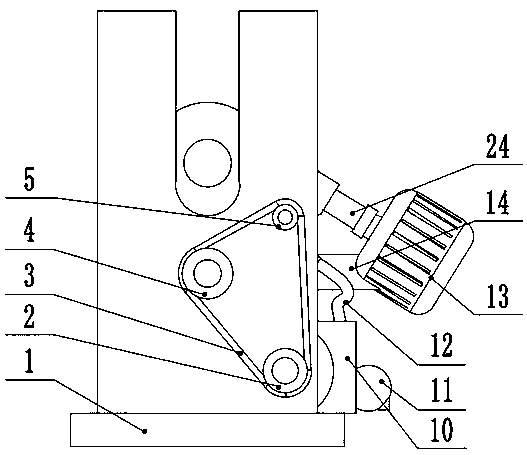

[0023] see Figure 1-3 , a dust removal device for floor mat production, comprising a bottom plate 1, side plates 6 are provided on the front and rear sides of the bottom plate 1, a placement groove 7 is arranged on the top of the side board 6, and a winding roller 8 is arranged inside the placement groove 7, and the side The bottom of the plate 6 is connected to the front and rear sides of the drive roller 21 in rotation. The right side of the bottom plate 1 is provided with a first drive motor 9. The output shaft of the first drive motor 9 is fixedly connected to the drive pulley 2, and the drive pulley 2 is connected by a belt 3. The first driven pulley 4, the first driven pulley 4 is fixedly connected to the front end of the driving roller 21, the right side of the side plate 6 is rotated to connect the front and rear sides of the screw mandrel 23, and the driving pulley 2 passes through the belt 3 Connect the second driven pulley 5, the second driven pulley 5 is fixedly c...

Embodiment 2

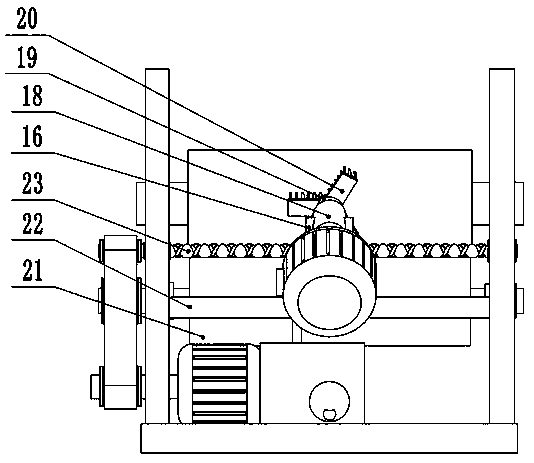

[0025] see image 3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the middle part of the upper surface of the bottom plate 1 is provided with a dust removal box 10, the top of the dust removal box 10 is connected to the bottom of the dust removal suction nozzle 17 through the air pipe 12, and the dust removal box The right side of 10 is provided with air pump 11. In order to prevent the dust sucked out by the dust removal nozzle 17 from leaking into the environment and affecting the working environment of the operator, a dust removal box 10 is arranged at the bottom of the bottom plate 1, and the dust extracted by the suction nozzle is filtered through the dust removal box 10, and when the device works for a period of time , it only needs to clean the dust removal box 10, which reduces the maintenance difficulty of the whole device.

[0026] In the implementation process of the present invention, start the first drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com