A leaf forming device

A molding device and dough leaf technology, applied in dough molding and cutting equipment, dough processing, dough sheeter/roller/rolling pin, etc., can solve the problems of easy sticking of dough skins and inability to reduce labor intensity, etc. , to achieve the effect of reducing manual labor, simple structure, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

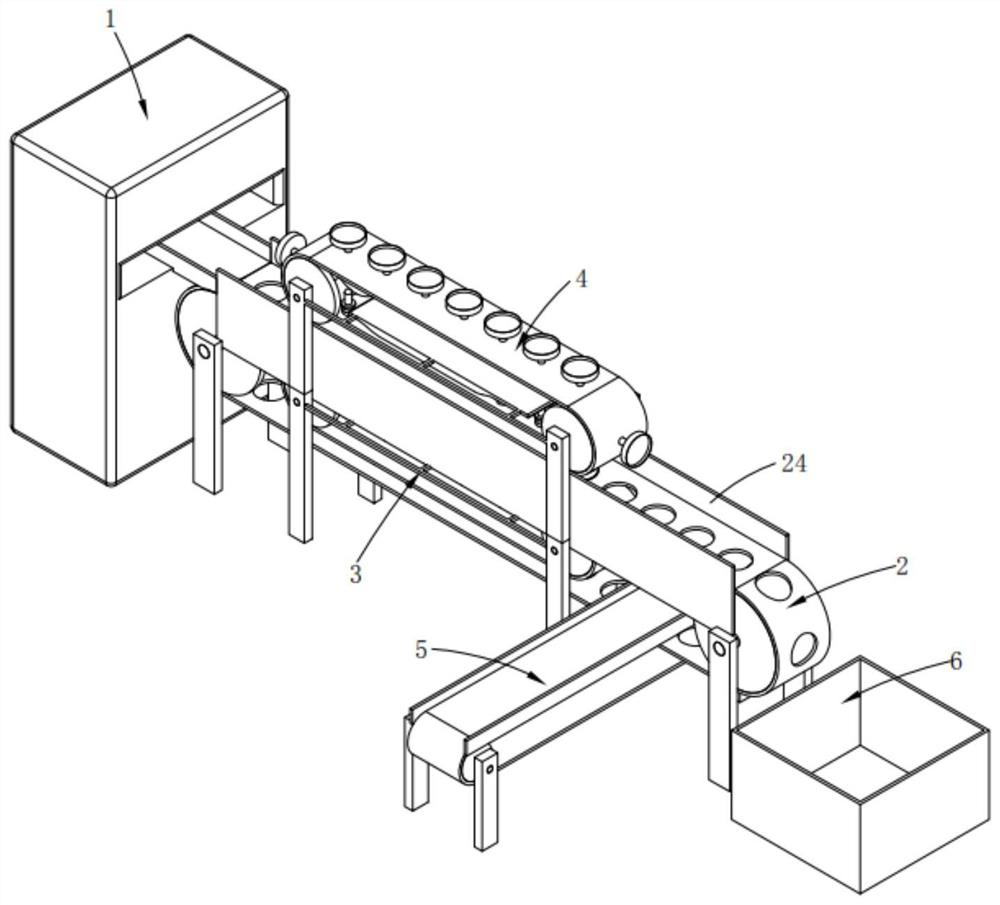

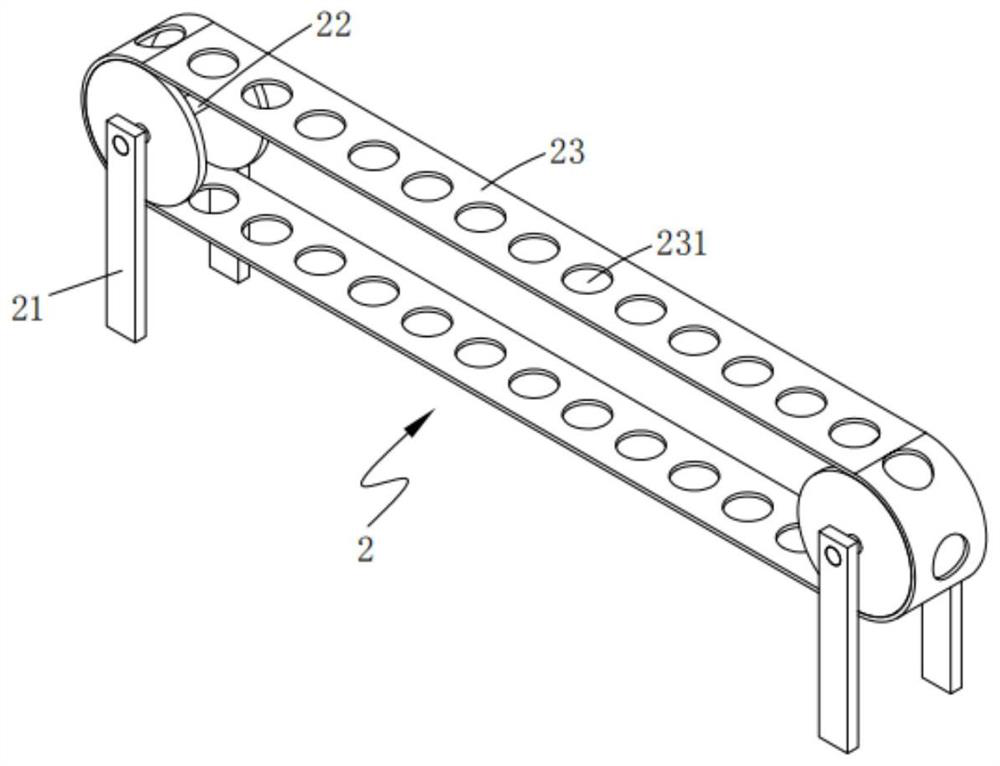

[0045] like figure 1 , 2, 3 and 4, a leaf molding device, which includes a profiling mechanism 1 and a first conveying mechanism 2 arranged at the output end of the profiling mechanism 1, the first conveying mechanism 2 includes a first bracket 21, a rotating Shaft 22 and first conveyor belt 23, the first bracket 21 points to the output end of the profiling mechanism 1, the two rotating shafts 22 are respectively rotated and arranged at both ends of the first bracket 21, and the first bracket 21 A conveyor belt 23 is sleeved outside the two rotating shafts 22, which picks up the dough 10 in the molding mechanism 1 and transports it. The first conveyor belt 23 is provided with through holes 231 in an array along its conveying direction; It also includes:

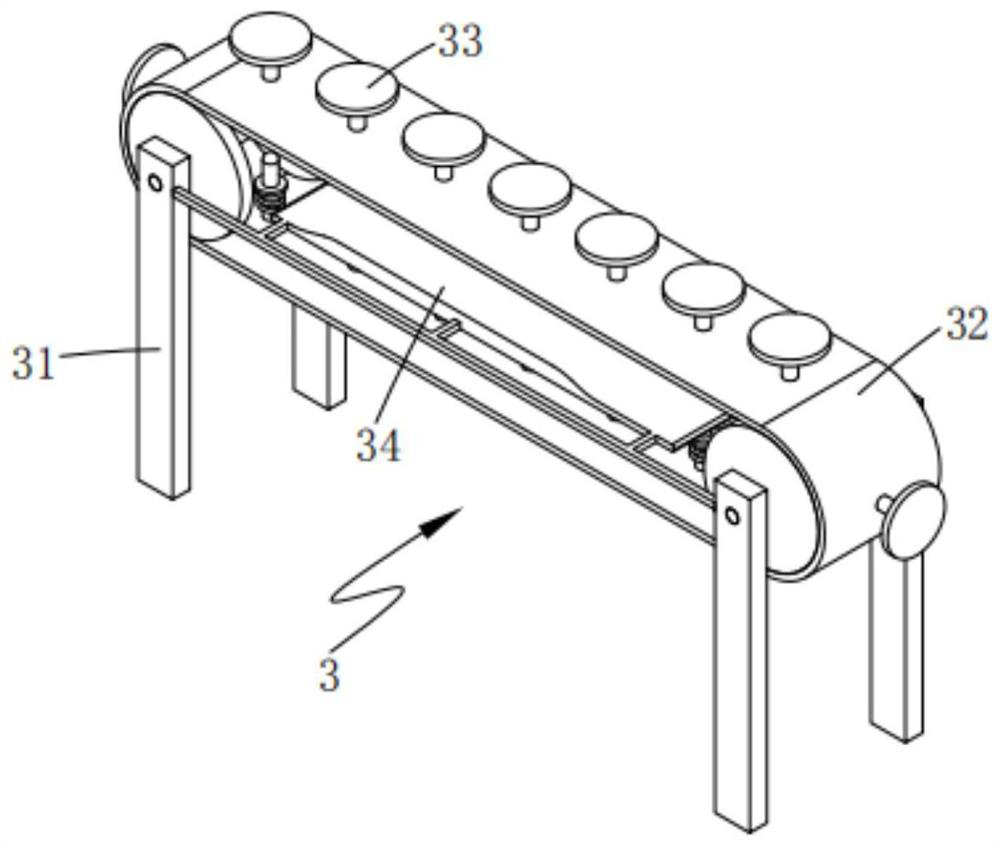

[0046] The supporting mechanism 3, the supporting mechanism 3 is arranged inside the first conveyor belt 23 along the conveying direction of the first conveying mechanism 2, and it is located between the two rotating shafts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com