A composite metal lithium negative electrode with filler and preparation method thereof

A technology of composite metal and lithium negative electrode, applied in the direction of negative electrode, active material electrode, battery electrode, etc., can solve complex and dangerous problems, and achieve the effect of improving cycle performance, simple operation, and slowing down the volume expansion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

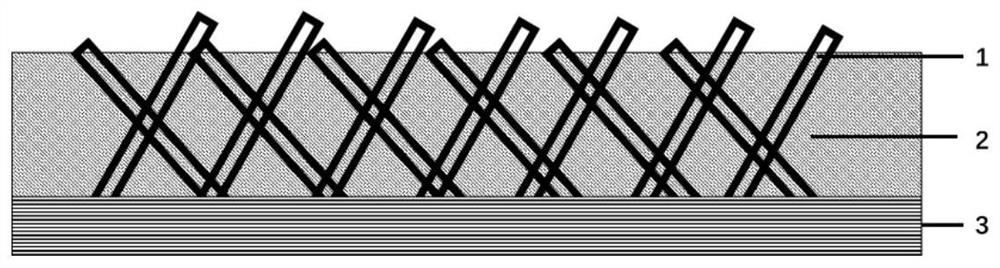

[0034] Using carbon paper as a skeleton material and polyacrylonitrile as a filler, a composite metal lithium negative electrode is obtained, which specifically includes metal lithium, carbon paper and polyacrylonitrile filled in the pore structure of the carbon paper. Prepare as follows:

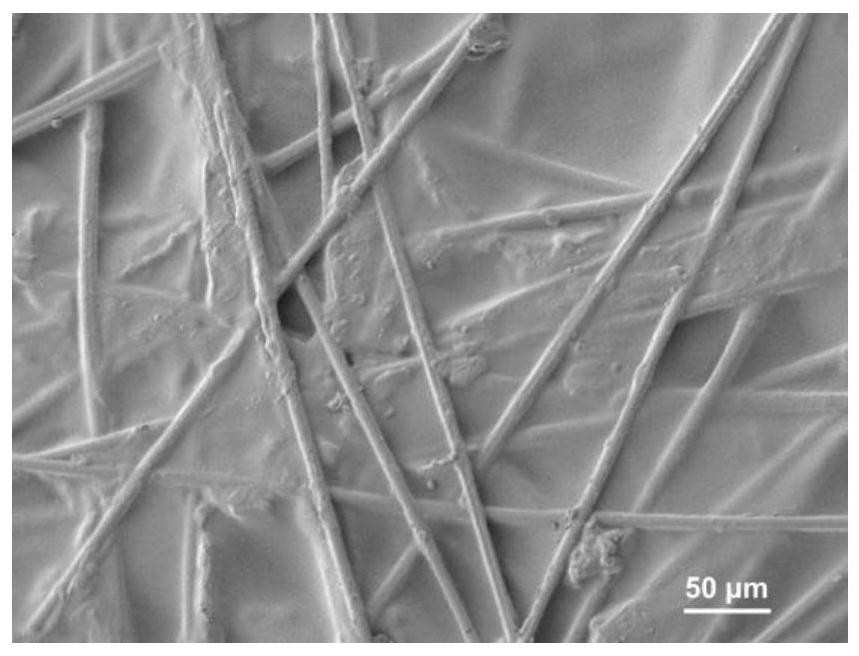

[0035] (1) Dissolve polyacrylonitrile in N-methylpyrrolidone, stir evenly until polyacrylonitrile can be completely dissolved in the solvent, and the slurry is relatively viscous, and the obtained slurry is coated on carbon paper (average pore size 100 μm), baked After 6 hours of dry treatment, polyacrylonitrile fills the pores of the carbon paper to obtain the treated carbon paper; as figure 2 Shown is the SEM image of carbon paper after polyacrylonitrile filled pores, from figure 2 It can be seen that the pores of the carbon paper are completely filled by polyacrylonitrile.

[0036] (2) Align and stack the treated carbon paper obtained in step (1) and the lithium strip with a thicknes...

Embodiment 2

[0040]A composite metal lithium negative electrode is obtained by using copper mesh as a skeleton material (average pore diameter of 100 μm) and polyacrylonitrile as a filler, which specifically includes metal lithium, copper mesh and polyacrylonitrile filled in the copper mesh structure.

[0041] Prepare as follows:

[0042] (1) Dissolve polyacrylonitrile in N-methylpyrrolidone, polyacrylonitrile can be completely dissolved in the solvent, coat the resulting slurry on the copper grid, dry for 6 hours, and fill the polyacrylonitrile into the copper mesh structure , to obtain the processed copper mesh skeleton;

[0043] (2) Align and stack the treated copper mesh skeleton obtained in step (1) and the lithium strip with a thickness of 50 μm, and roll it through a rolling mill at a pressure of 8 MPa and a temperature of 60° C. A copper mesh / lithium ribbon composite metal lithium negative electrode with polyacrylonitrile-filled pores was obtained.

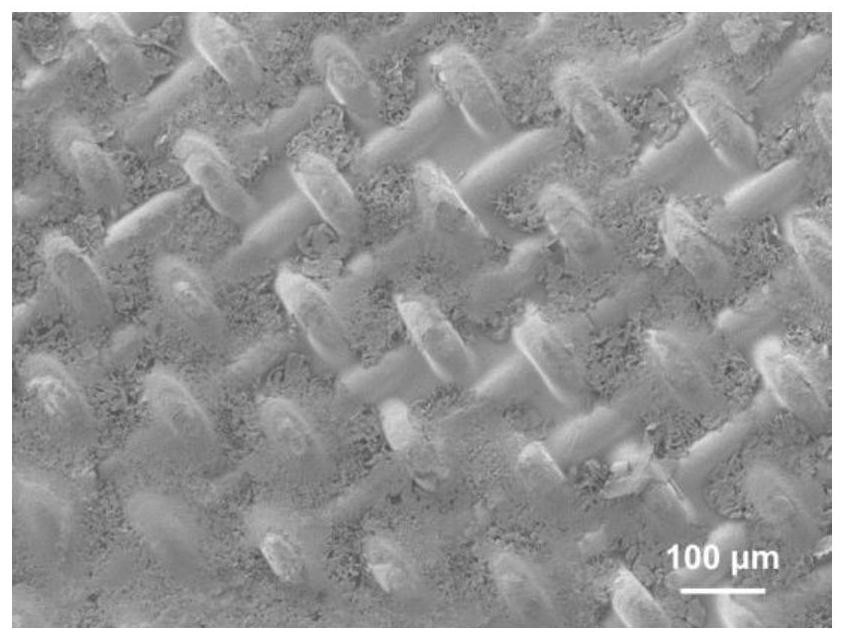

[0044] Such as image 3 The ...

Embodiment 3

[0050] Using carbon paper as the skeleton material and a mixture of polyacrylonitrile and polyethylene as the filler, a composite metal lithium negative electrode is obtained, which specifically includes metal lithium, carbon paper, and polyacrylonitrile and polyethylene filled in the carbon paper pore structure . Prepare as follows:

[0051] (1) Dissolve polyacrylonitrile and polyethylene in acetone, coat the resulting solution on carbon paper (average pore size 100 μm), dry for 6 hours, fill the pores of the carbon paper with polyacrylonitrile and polyethylene, and obtain Treated carbon paper skeleton;

[0052] (2) Align and stack the treated carbon paper obtained in step (1) and the lithium tape with a thickness of 33 μm, and press it through a punching machine at a pressure of 0.1 MPa and a temperature of 20°C; after stamping, the ultra-thin lithium tape is pasted with carbon paper combined to obtain a carbon paper / lithium ribbon composite metal lithium negative electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com