Battery

A battery and cell technology, applied in the manufacturing of batteries, battery pack components, and secondary batteries, can solve the problems of irregular overall structure of the battery, complicated assembly process, and different battery performance, and achieve compact structure, easy assembly, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

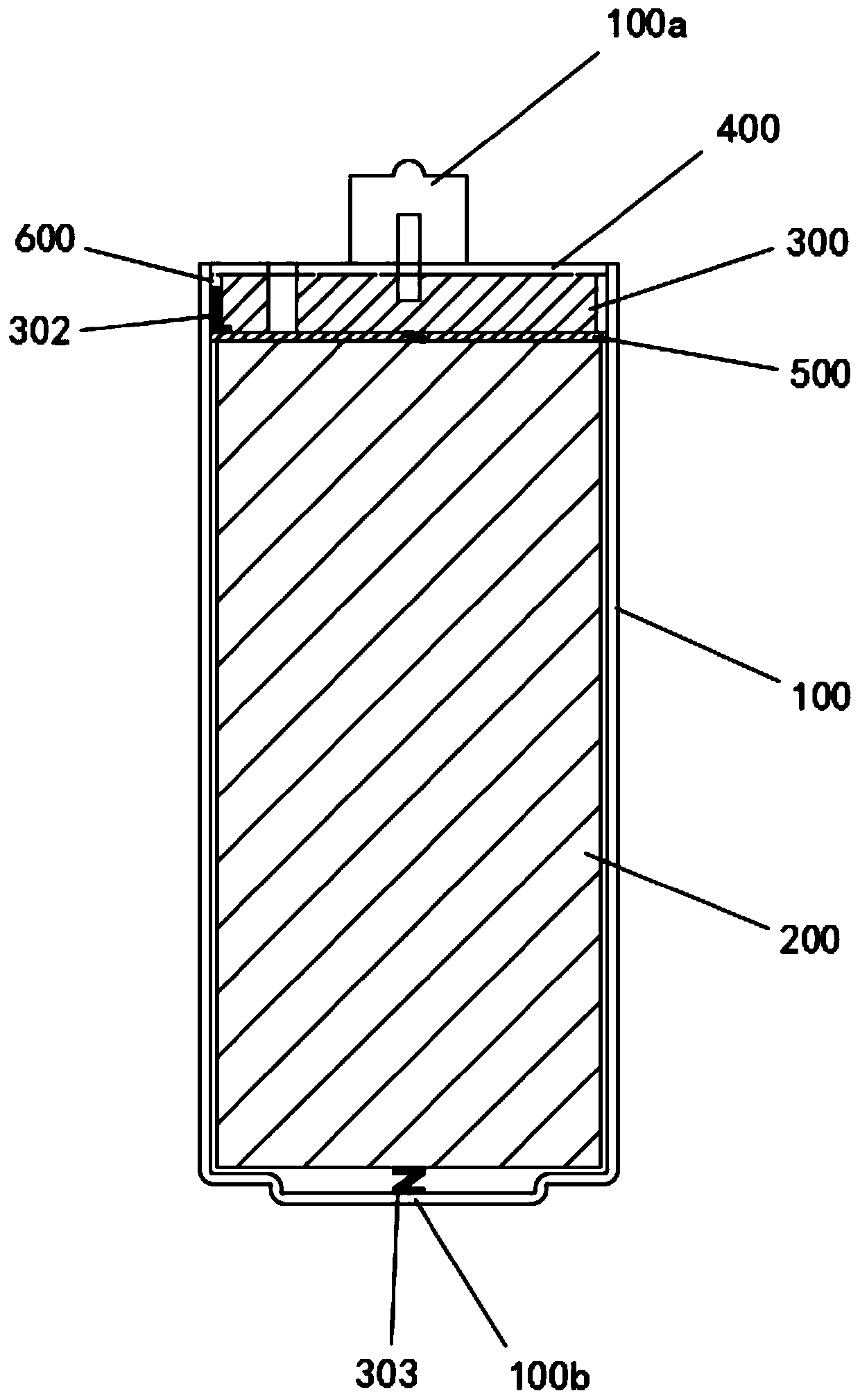

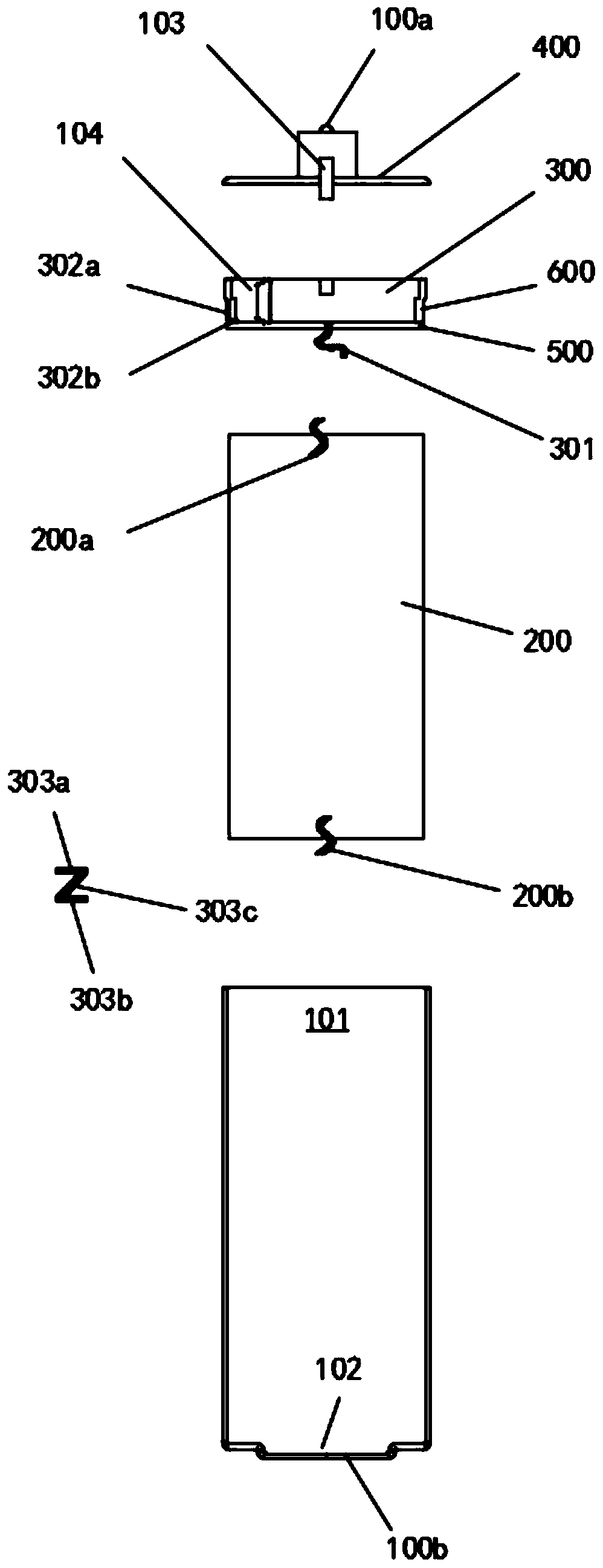

[0037] Such as figure 1 As shown in -4, a battery includes a casing 100 , a cell 200 , a chip 300 , a casing cover 400 , an insulating film 500 and a fixing collar 600 .

[0038] The shell 100 is preferably a steel shell with good structural stability. For example, 304 steel deep-drawing material is used to pass through multiple progressive stamping dies, and it is stamped to the design specification size; the upper end of the shell 100 is opened 101, and the battery cell 200 occupies the shell 100 The main space inside is biased toward the lower end of the housing 100 , the chip 300 is located above the cell 200 , and the housing cover 400 is located above the chip 300 , and the opening 101 is closed by the housing cover 400 .

[0039]A layer of insulating film 500 is laid between the chip 300 and the battery cell 200, which can isolate the direct contact between the battery cell 200 and the chip 300 and avoid interference. The insulating film 500 can be prefabricated on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com