Batch compounding method of double-frequency intelligent tags

A smart label and batch technology, applied in the field of batch compounding of dual-frequency smart labels, can solve problems such as increasing the convenience of use and reducing the cost of using smart labels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

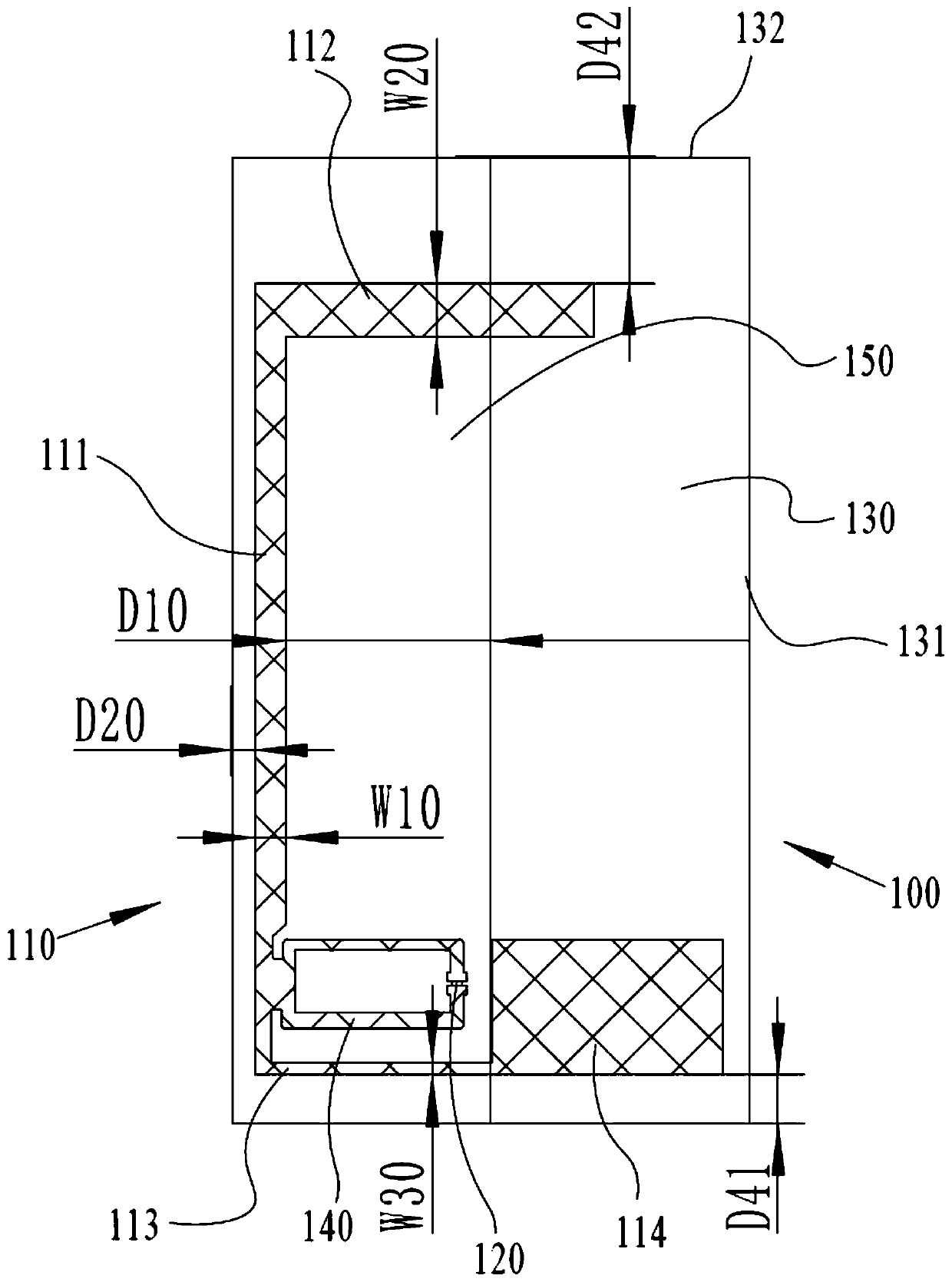

[0070] The embodiment of the present invention discloses a batch compounding method of dual-frequency smart labels, which includes the following operating procedures:

[0071] S10), UHF smart label unwinding mechanism is used for continuous unwinding of UHF smart label film and the UHF smart label film is conveyed to the first composite roller, and high frequency smart label unwinding mechanism is used for high frequency Continuous unwinding of the smart label film and conveying the UHF smart label film to the second composite roller. The UHF smart label film includes a number of UHF smart labels distributed continuously and evenly at intervals, each UHF smart label There is a blank area on the top; the high-frequency smart label film includes a number of high-frequency smart labels distributed continuously and evenly at intervals;

[0072] S20). The first composite roller and the second composite roller perform counter-roll movement. Before entering the counter-roll movement, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com