Friction-free linker

A linker, frictionless technology, applied to rotating parts, bearings, shafts and other directions that resist centrifugal force, can solve the problems of high noise, easy wear, large heat generation, etc., and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

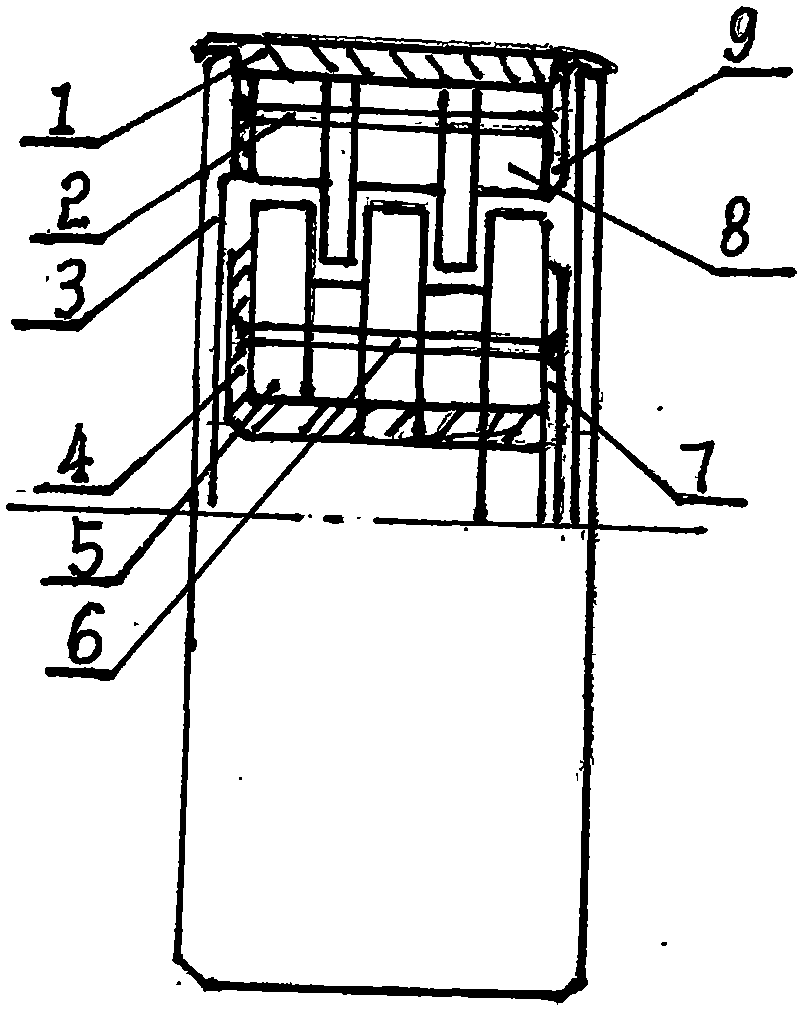

[0010] The specific embodiment of the present invention is described now in conjunction with accompanying drawing. The present invention mainly consists of outer ring 1, outer ring rivets 2, dust cover 3, inner ring 4, inner ring core 5, inner ring rivets 6, inner ring auxiliary cover 7, outer ring core 8, outer ring auxiliary cover 9 and other parts composition. The inner ring 4 is made into a disc shape and has a hollow body with a boss in the center. The inner ring core 5 is set on the boss, and the hollow in the center is a place for the user to assemble with the shaft or other parts when using. The outer ring 1 is cylindrical, and a part of the inner part is removed to leave a slightly larger hole, and the hollowed out part is embedded and fixed with the outer ring core 8 by rivets. The outer ring 1 and the inner ring 4 can be made of non-magnetic materials such as aluminum alloy or stainless steel, and the end faces of one side or both sides of the outer ring 1 have gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com