Assembly member and mounting method

A technology of components and locking parts, which is applied in the direction of building components, building structures, floors, etc., can solve the problems of difficult installation and recycling of existing walls, problems in the maintenance of prefabricated walls, and complex construction techniques, etc., to achieve Convenient assembly and later disassembly and reassembly, shortening the construction period, and strong installation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

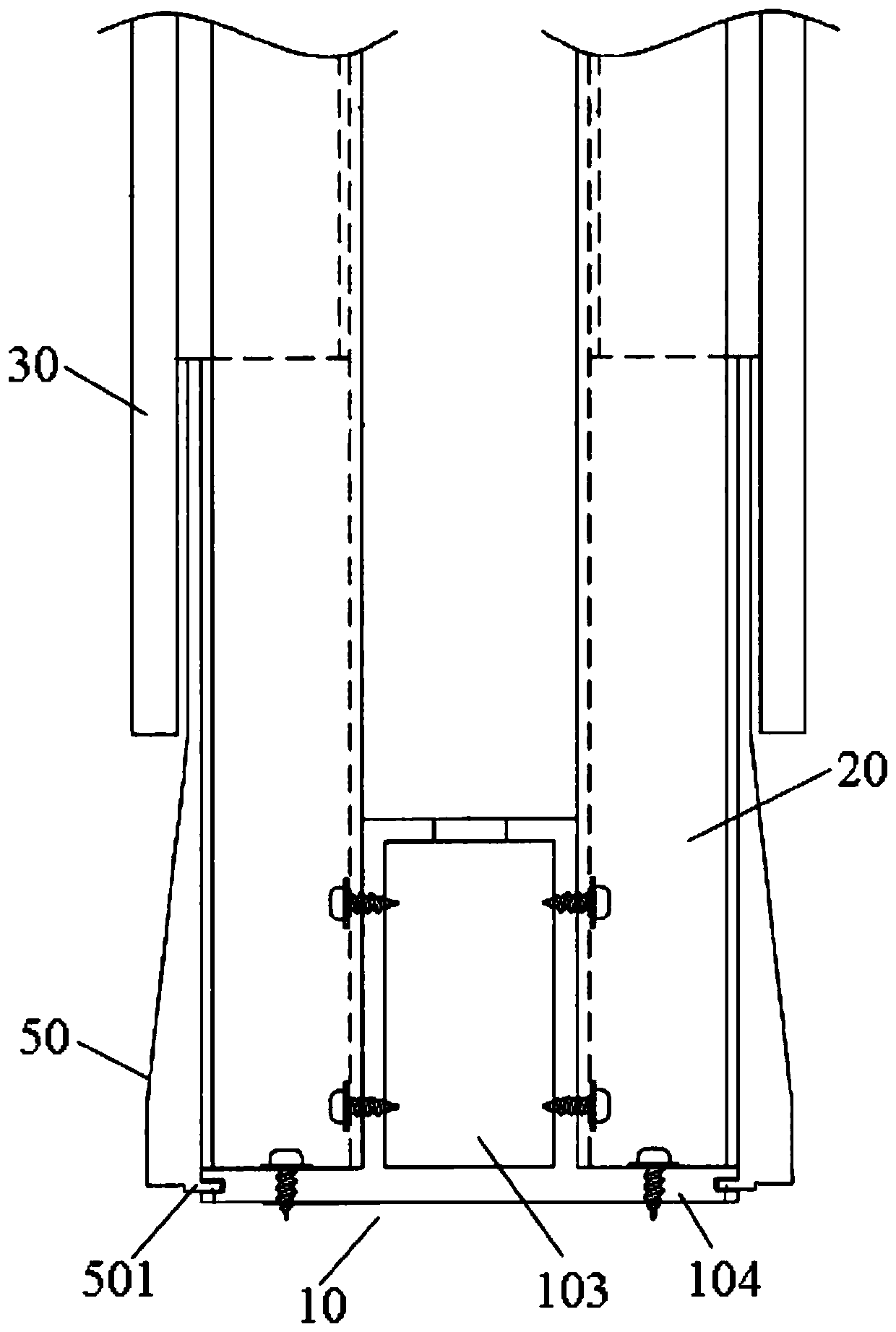

[0040] as attached figure 1 As shown, a component for assembly includes a frame and a panel 30, and the panel 30 is fixed on the frame.

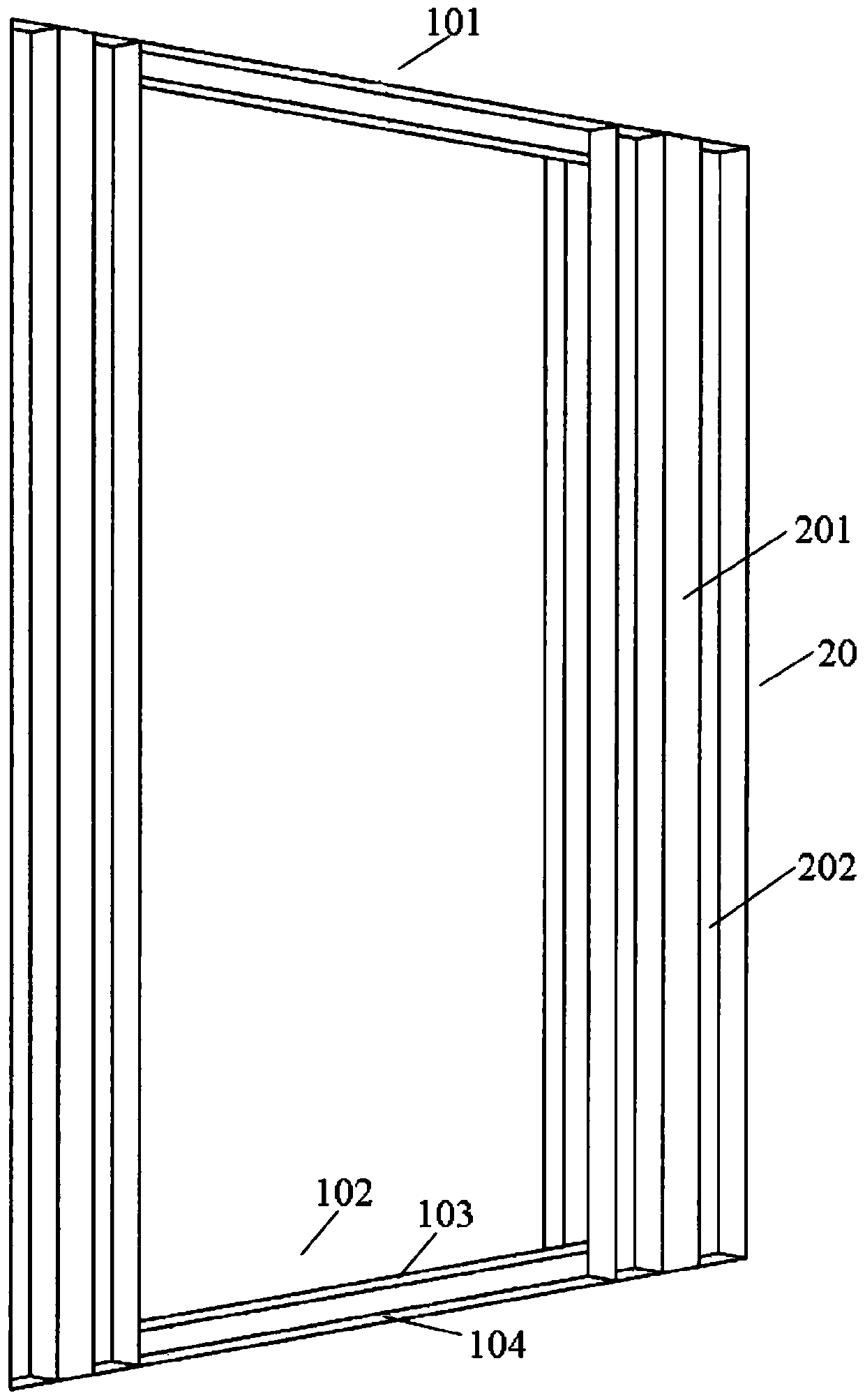

[0041] as attached figure 2 As shown, the frame includes a fixed plate 10 and a fixed column 20, the fixed plate 10 includes a first fixed plate 101 and a second fixed plate 102, and the two ends of the fixed column 20 are respectively fixed on the first fixed plate 101 and the second fixing plate 102 ; the panel 30 is fixed on the fixing column 20 .

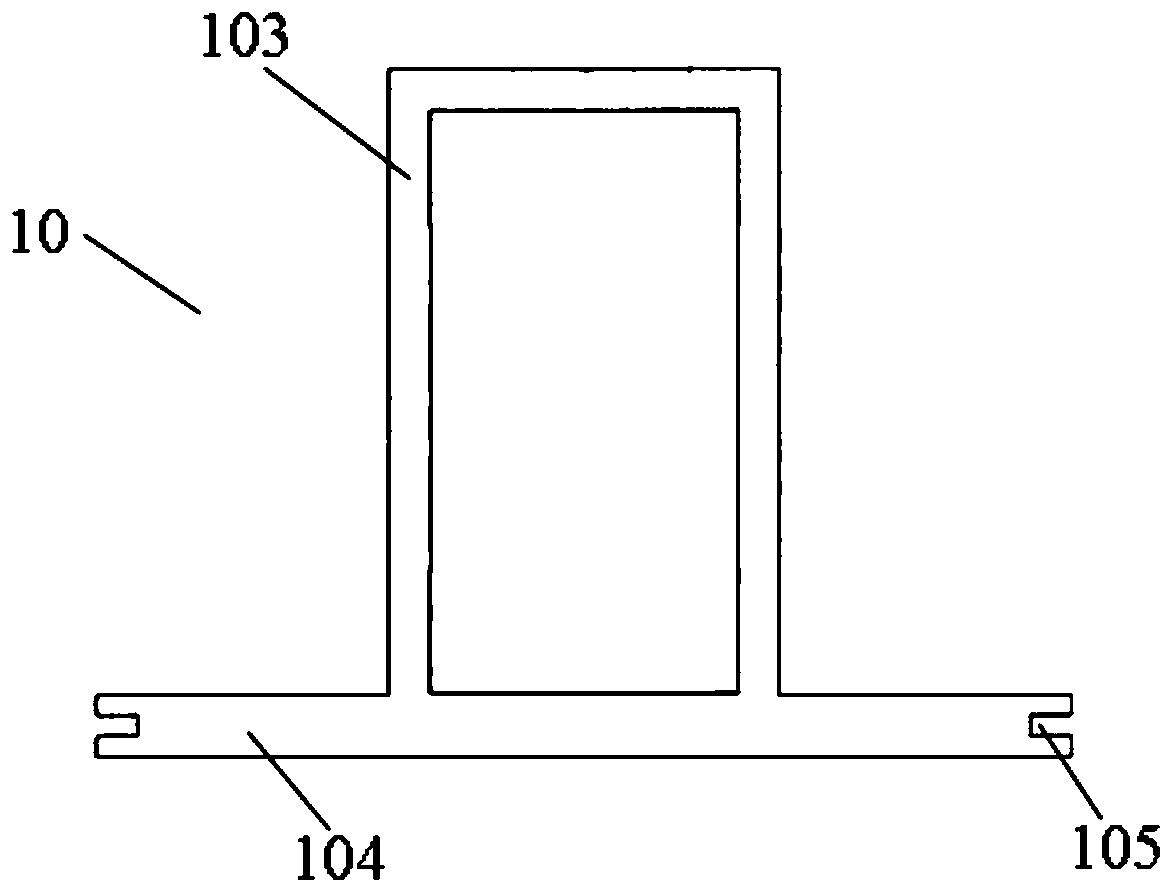

[0042] as attached image 3 As shown, the fixed plate 10 is a "convex" structure, and a first boss 103 is arranged in the middle. The first boss 103 is a hollow structure, and side plates 104 are arranged on both sides of the first boss 103. The side board 104 is used to be fixed on the ceiling or the floor.

[0043] Preferably, a through hole is provided above the first boss 103, and the through hole is used for wires to pass through.

[0044] as attached Figure 4 As shown, the fixing...

Embodiment 2

[0051] Based on the above-mentioned embodiment 1, a method for installing components for assembling comprises the following steps:

[0052] 101. First fix the first fixing plate 101 and the second fixing plate 102 on the ceiling and the floor respectively by screws, that is, the side plates 104 of the first fixing plate 101 and the second fixing plate 102 are fixed on the ceiling and the floor by screws;

[0053] 102. After step 101, fix the two ends of the fixed column 20 on the first fixed plate 101 and the second fixed plate 102 respectively, that is, the grooves 202 at both ends of the fixed column 20 are fixed on the first fixed plate 101 and the second fixed plate 102 by screws. On the first boss 103 of the fixed plate 102;

[0054] 103. After step 102, fix one side of the panel 30 on the fixed column 20 through the coupling 40, firstly connect the panel 30 to the coupling 40 with screws, and then fix the coupling 40 on the fixed column 20 Inside the groove 202;

[005...

Embodiment 3

[0058] Based on the above-mentioned embodiment 1, a method for installing components for assembling comprises the following steps:

[0059] 101. First, fix the first fixing plate 101 and the second fixing plate 102 to the ceiling and the floor respectively by screws, that is, the side panels 104 of the first fixing plate 101 and the second fixing plate 102 are fixed to the ceiling and the floor by screws superior;

[0060] 102. After step 101, fix the two ends of the two fixed columns 20 on the first fixed plate 101 and the second fixed plate 102 respectively, that is, the grooves 202 at both ends of the fixed column 20 are fixed on the first fixed plate 101 and the second fixed plate 102 by screws. On the first boss 103 of the second fixing plate 102, two fixing columns 20 are fixed on both sides of the fixing plate 10 front and back;

[0061] 103. After step 102, fix one side of the two panels 30 on the two front and rear fixing columns 20 respectively through the coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com