Lever type flip automatic flushing closestool

An automatic flushing and lever-type technology, which is applied in the field of flushing toilets, can solve the problems of being unable to maintain water storage and lack of water in the water tank at the same time, and achieve the effects of ensuring the use of water storage, increasing production costs, and simplifying the flushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solution of the present invention.

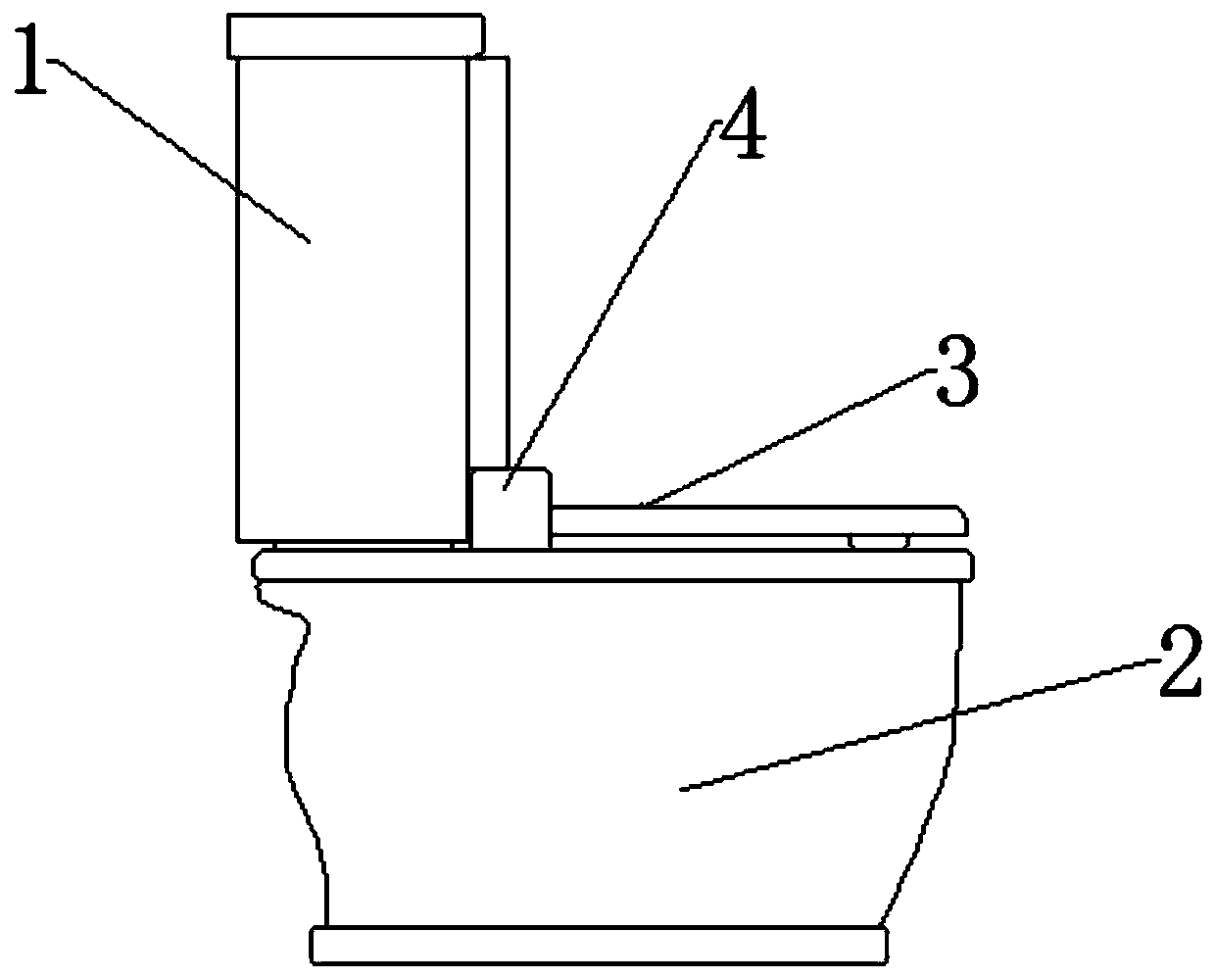

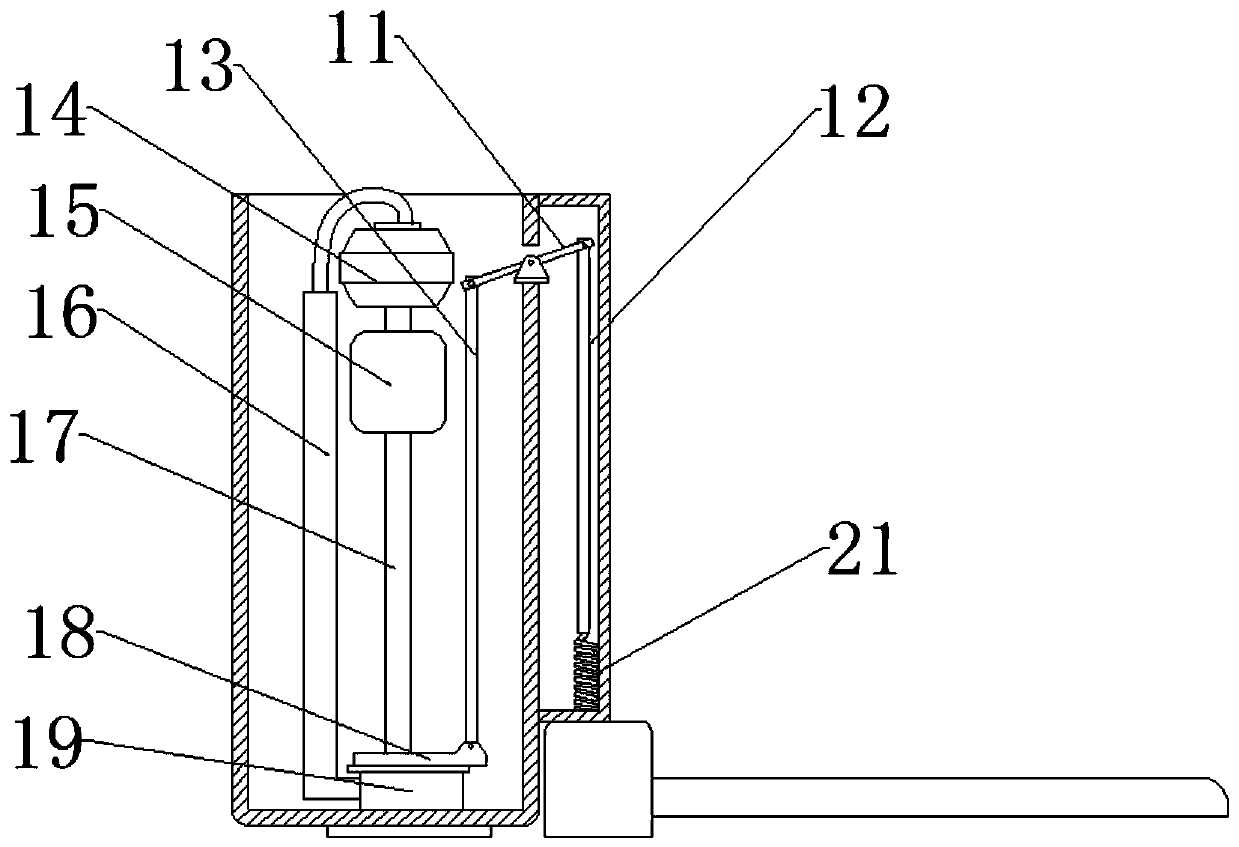

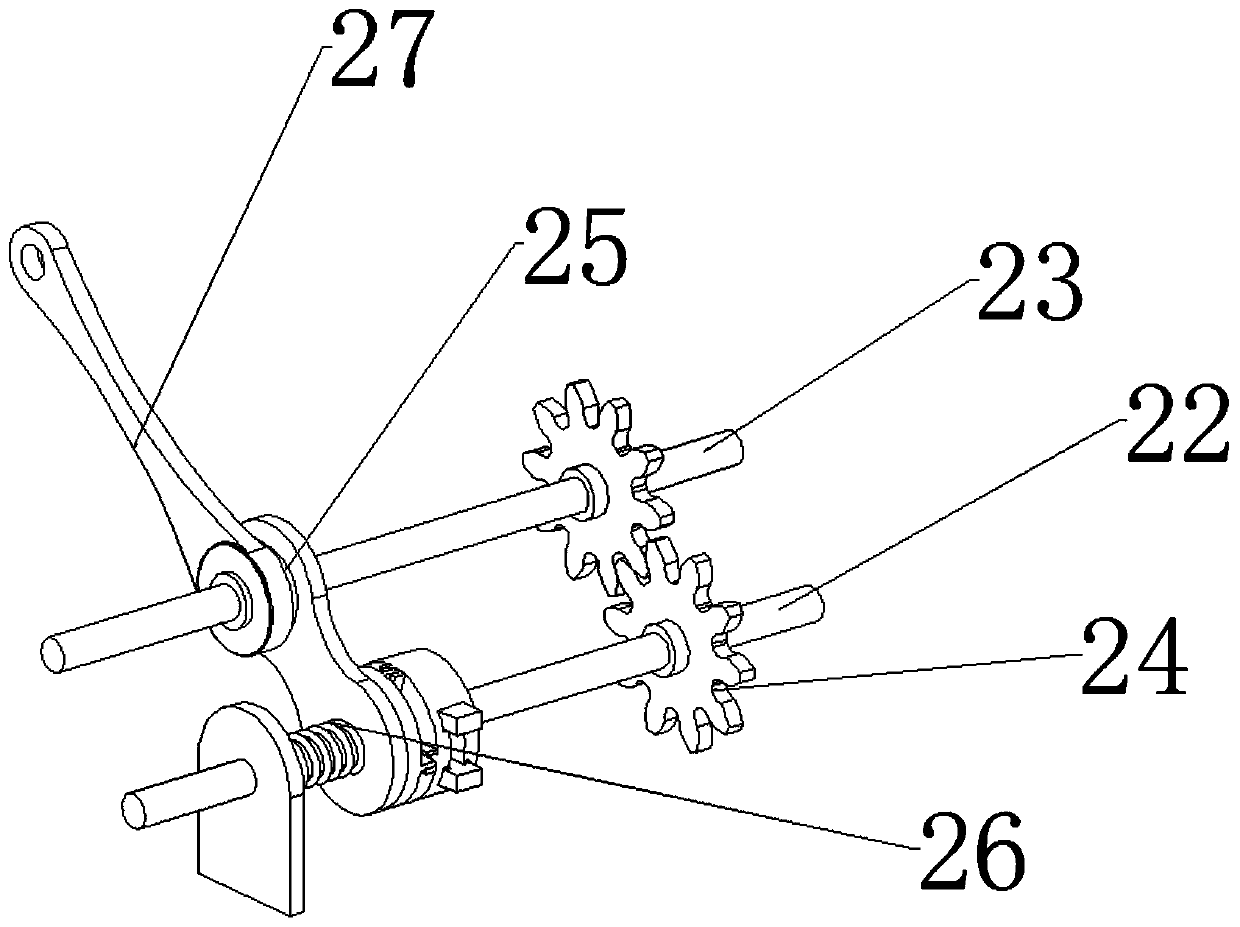

[0019] Such as Figure 1-5 As shown, the present invention provides a lever-type flip-top automatic flush toilet, including a toilet body 2, a toilet cover 3, and a water tank 1. The toilet cover 3 is rotatably installed on the toilet cover shaft 22 provided with a damping shaft structure 4 On the toilet body 2, the water tank 1 is provided with a drain pipe 17 communicating with the inside of the toilet body 2, and the outlet of the drain pipe 17 is provided with a flush valve 18, which is opened by an upward connecting rod 13. It is characterized in that: the water tank 1 is provided with a lever mechanism, the connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com