A silicone thermally conductive potting silicone with excellent performance

A technology of heat conduction potting and silicone, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of high product viscosity, poor oil leakage performance, difficult adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

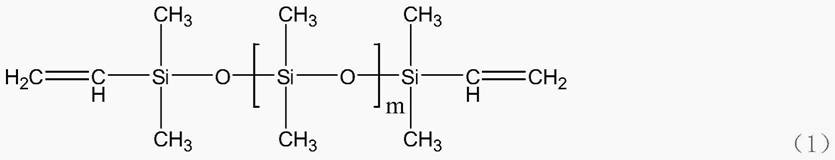

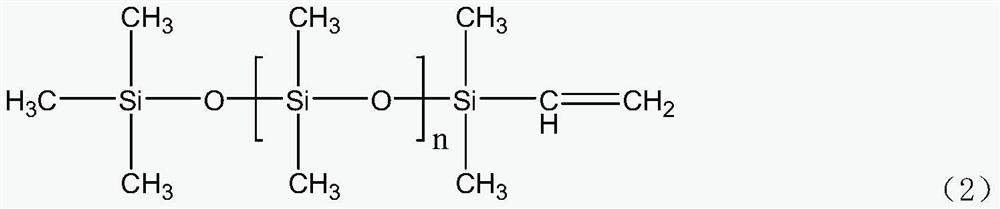

[0049] A component: successively weigh 7.0 g of methyl vinyl polysiloxane-1 (wherein m=48, vinyl content is 1.0 wt%) with a viscosity of 100 mPa.s such as structural formula (1); the viscosity is 50 mPa.s 8.5g of methyl vinyl polysiloxane-2 (where n=45, vinyl content is 0.80wt%) such as structural formula (2); 85g of thermal conductive powder; 1.5g of adhesive such as structural formula (4) (wherein K 1 =7,K 2 =4); Color paste 0.35g; Catalyst 0.04g of 5000ppm; Join in double planetary mixing tank, mix under vacuum state, promptly obtain A component;

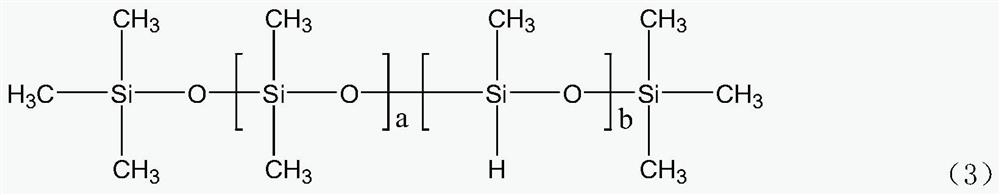

[0050] Component B: Weigh 38g of methylvinyl polysiloxane-1 (wherein m=48, vinyl content is 1.0wt%) with a viscosity of 100mPa.s such as structural formula (1); the viscosity is 50mPa.s such as 3.0g of methyl vinyl polysiloxane-2 (wherein n=45, vinyl content is 0.80wt%) of structural formula (2); 84g of heat conducting powder; viscosity is 45mPa.s as the crosslinking agent of structural formula (3) (where a=12, b=14, hydrogen ...

Embodiment 2

[0052] Component A: Weigh 6.5g of methylvinyl polysiloxane-1 (wherein m=48, vinyl content is 1.0wt%) with a viscosity of 100mPa.s such as structural formula (1); the viscosity is 50mPa.s Such as structural formula (2) methyl vinyl polysiloxane-2 (wherein n=45, vinyl content is 0.80wt%) 9g; Thermal conductive powder 84g; Such as structural formula (4) adhesive 1.0g (wherein K 1 = 6,K 2 =5); Color paste 0.30g; Catalyst 0.05g of 5000ppm; Join in double planetary mixing kettle, mix under vacuum state, promptly obtain A component;

[0053] B component: successively weigh 36g of methylvinyl polysiloxane-1 (wherein m=48, vinyl content is 1.0wt%) whose viscosity is 100mPa.s such as structural formula (1); viscosity is 50mPa.s such as 3.5g of methyl vinyl polysiloxane-2 (wherein n=45, vinyl content is 0.80wt%) of structural formula (2); 85g of heat conducting powder; viscosity is 45mPa.s as the crosslinking agent of structural formula (3) (where a=12, b=14, hydrogen content is 0.35wt...

Embodiment 3

[0055]A component: successively weigh 7.5g of methylvinyl polysiloxane-1 (wherein m=45, vinyl content is 1.05wt%) with a viscosity of 95mPa.s such as structural formula (1); the viscosity is 55mPa.s Such as structural formula (2) methyl vinyl polysiloxane-2 (wherein n=50, vinyl content is 0.70wt%) 8g; Heat conduction powder 86g; Such as structural formula (4) adhesive 2.0g (wherein K 1 =8,K 2 =3); Color paste 0.0.4g; Catalyst 0.03g of 5000ppm; Join in double planetary mixing kettle, mix under vacuum state, promptly obtain A component;

[0056] Component B: Weigh 40 g of methylvinylpolysiloxane-1 (wherein m=50, vinyl content is 0.95wt%) whose viscosity is 105mPa.s such as structural formula (1); viscosity is 45mPa.s such as 3.0g of methyl vinyl polysiloxane-2 (wherein n=40, vinyl content is 0.85wt%) of structural formula (2); 83g of heat conducting powder; viscosity is 45mPa.s as the crosslinking agent of structural formula (3) (where a=10, b=16, hydrogen content is 0.40wt%) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com