Electric traction locomotive operation overvoltage suppression control system and method

A technology of operating overvoltage and electric traction, which is applied to vehicle components, installation along the driving track, transportation and packaging, etc. It can solve the problems of current back-channeling to the car body, abnormal shaft temperature, and car body heating, etc., so as to suppress the car body Effects of circulating current, reducing insulation breakdown, and increasing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

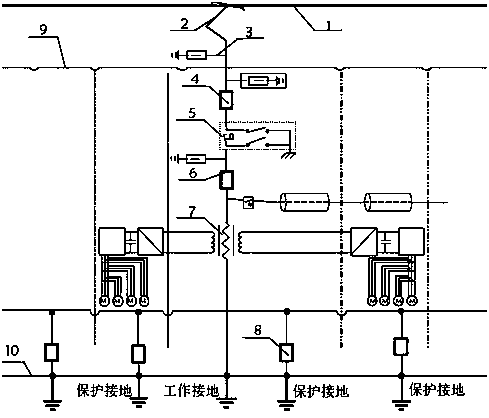

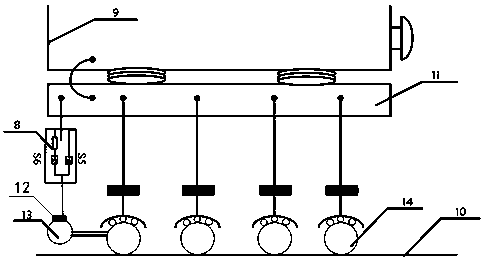

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. An electric traction locomotive operation overvoltage suppression control system, such as figure 1 As shown, it includes catenary 1, pantograph 2, lightning arrester 3, hoisting bow overvoltage suppressor 4, circuit breaker 5, circuit breaker operation overvoltage suppressor 6, current transformer, and main transformer 7 in the train traction power supply system , high-voltage cables, a new protective grounding device 8, and a train body 9.

[0039] When the train is working normally, the hoisting bow overvoltage suppression device 4, the circuit breaker operation overvoltage suppressor 6, and the new protective grounding device 8 automatically operate according to the state of the pantograph 2 and the circuit breaker 5. At the same time, it can also be monitored and manually controlled by the cab.

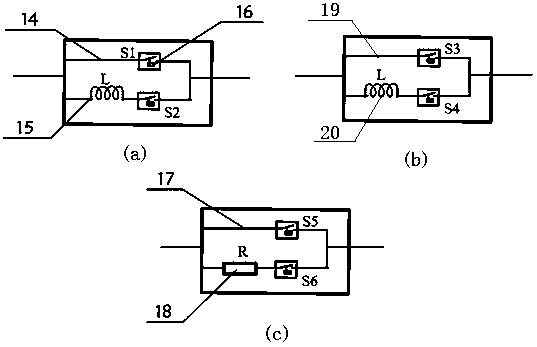

[0040] The lifting bow overvoltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com