Box pasting glue avoiding device

A technology of avoiding glue and gluing boxes, applied in the directions of packaging, transportation and packaging, box making operations, etc., can solve the problems of not being able to apply glue at the socket, increasing the production cost of enterprises, and difficult to guarantee the quality of gluing, so as to meet the production quality of products. , The effect of reducing production cost and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

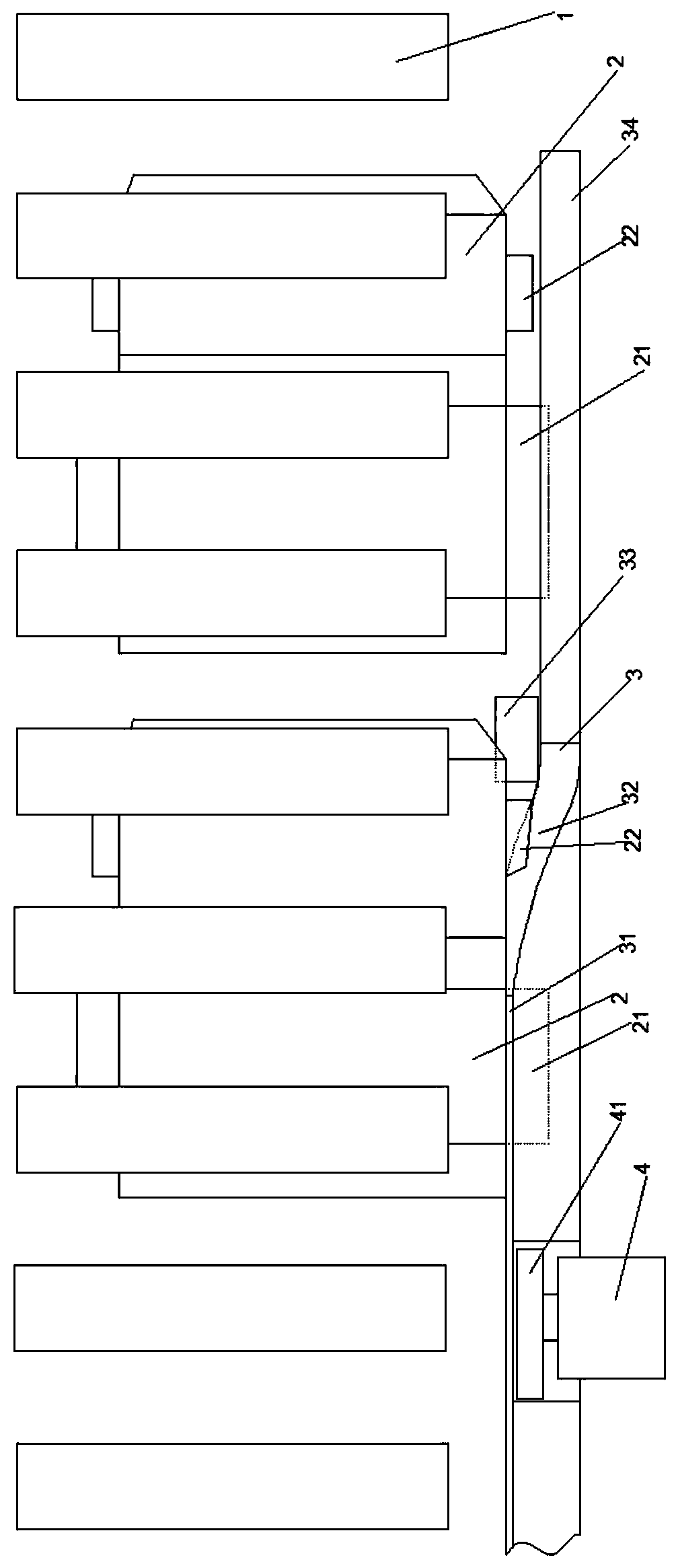

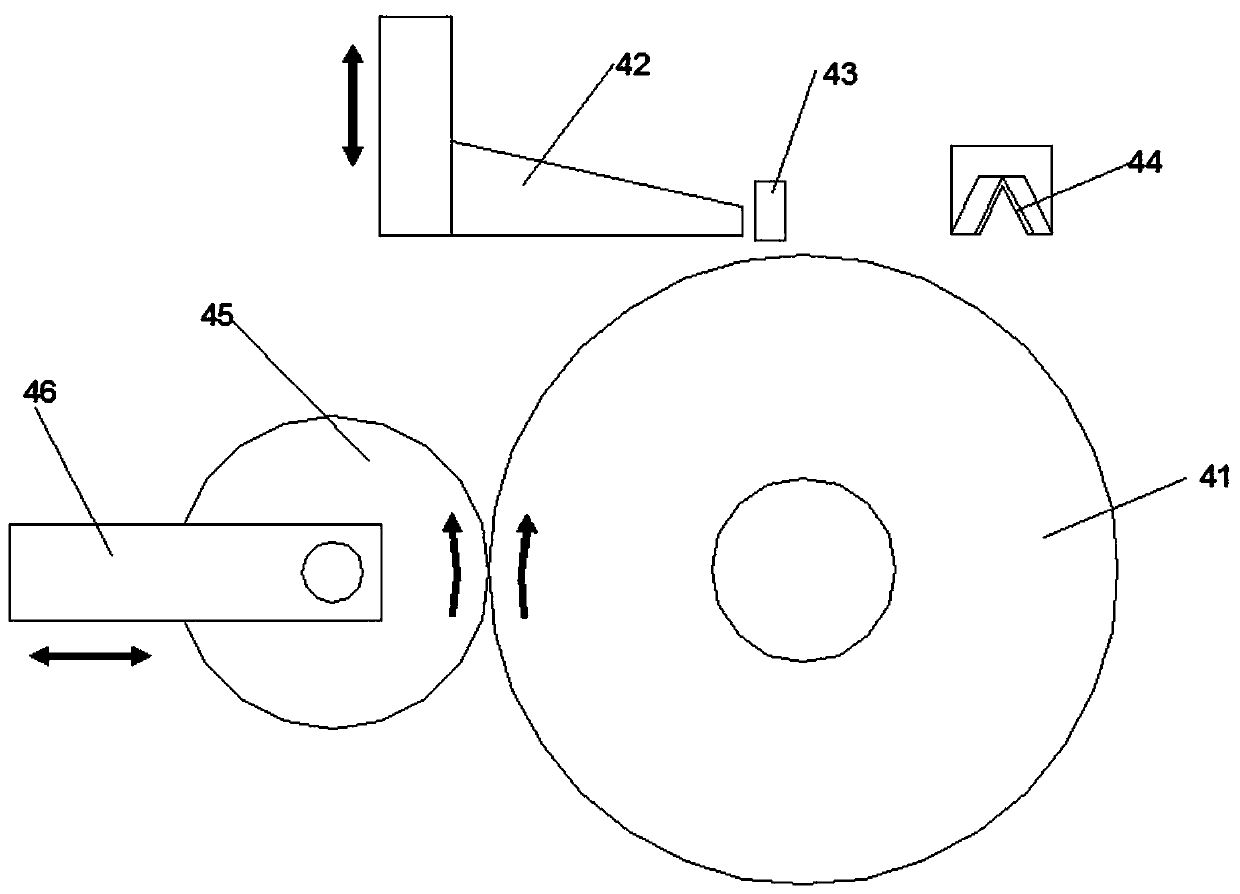

[0021] refer to Figure 1-2 As shown, a glue avoiding device for pasting boxes includes a conveying line and a glue avoiding track for transporting the box body 2. A guide track 34 is arranged on one side of the conveying line, and the opening 21 and the socket 22 of the box body 2 are located on the side of the conveying line. Driven by the conveying line, it moves along the direction of the guide track 34, and the rubber avoiding track is arranged on the guide track 34;

[0022] One side of the rubber avoiding track is provided with a jacking part, and the jacking part guides the socket 22 of the box body 2 to the rubber avoiding track, and the rubber avoiding track folds the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com