Online automatic dressing device for high-precision CBN grinding wheel

A dressing device, high-precision technology, applied in the direction of grinding drive device, abrasive surface adjustment device, grinding machine tool parts, etc., can solve the problems of long product processing cycle, high work intensity, low work efficiency, etc., to reduce production The time required, the improvement of production efficiency, and the effect of good trimming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

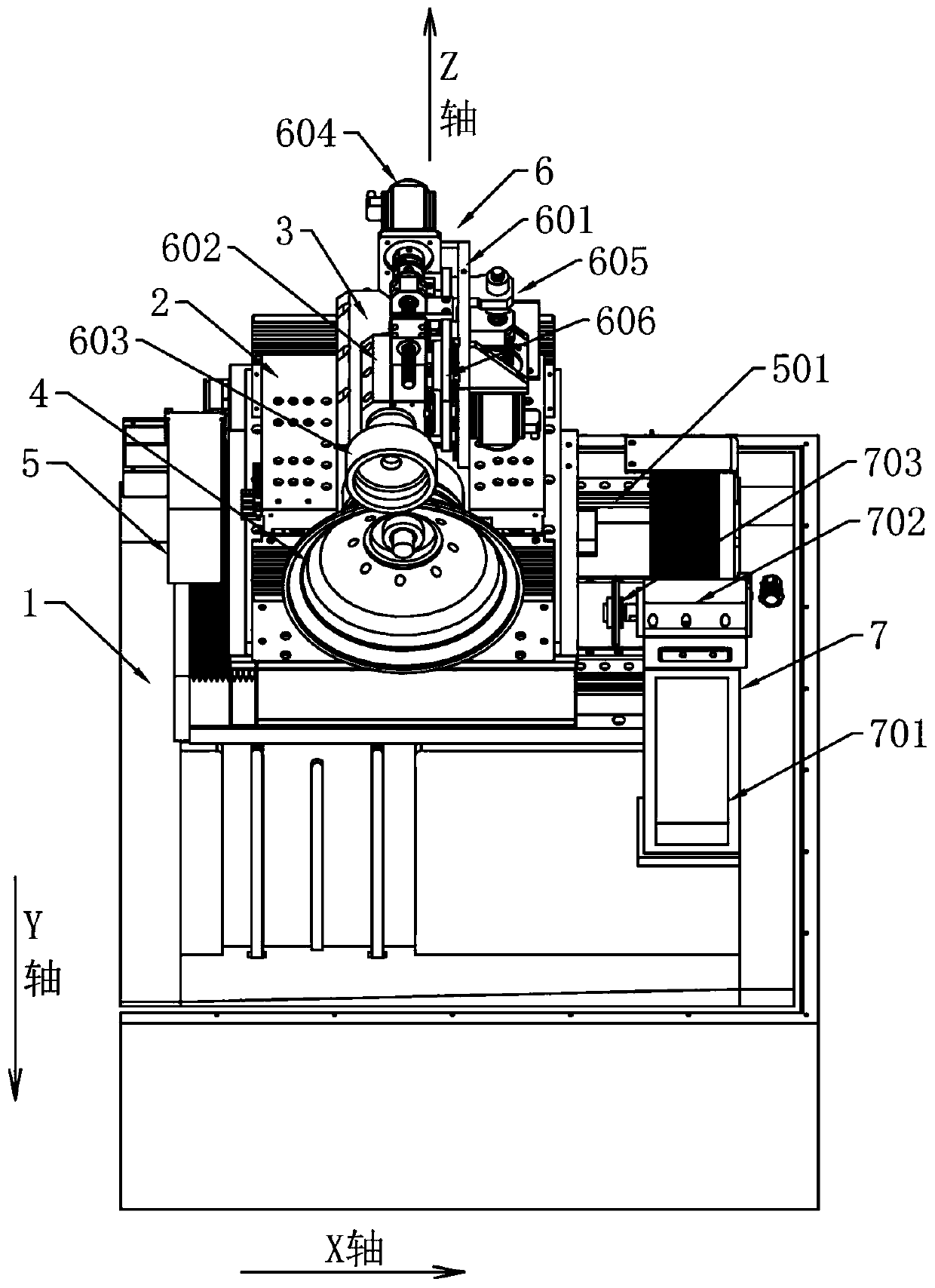

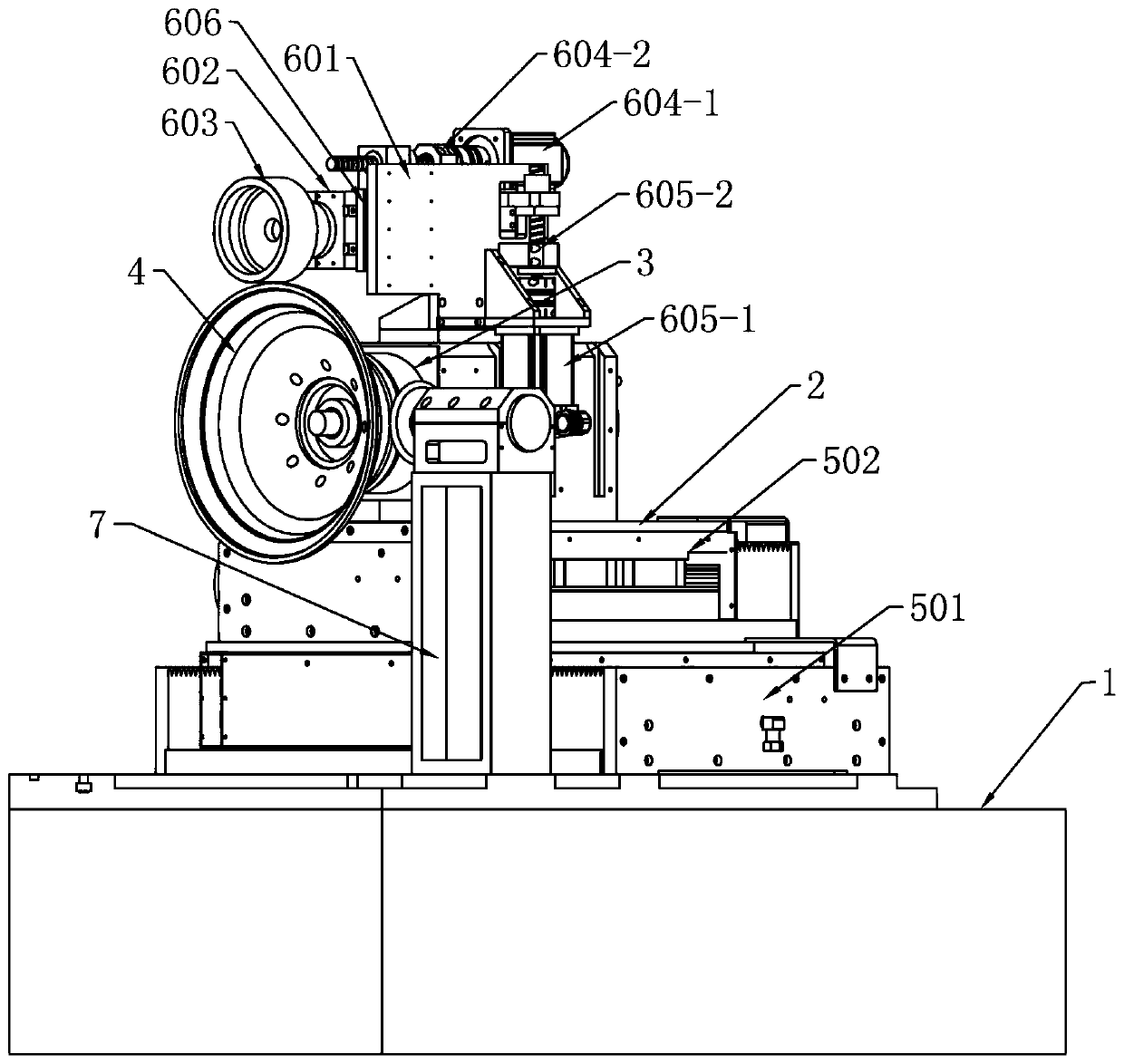

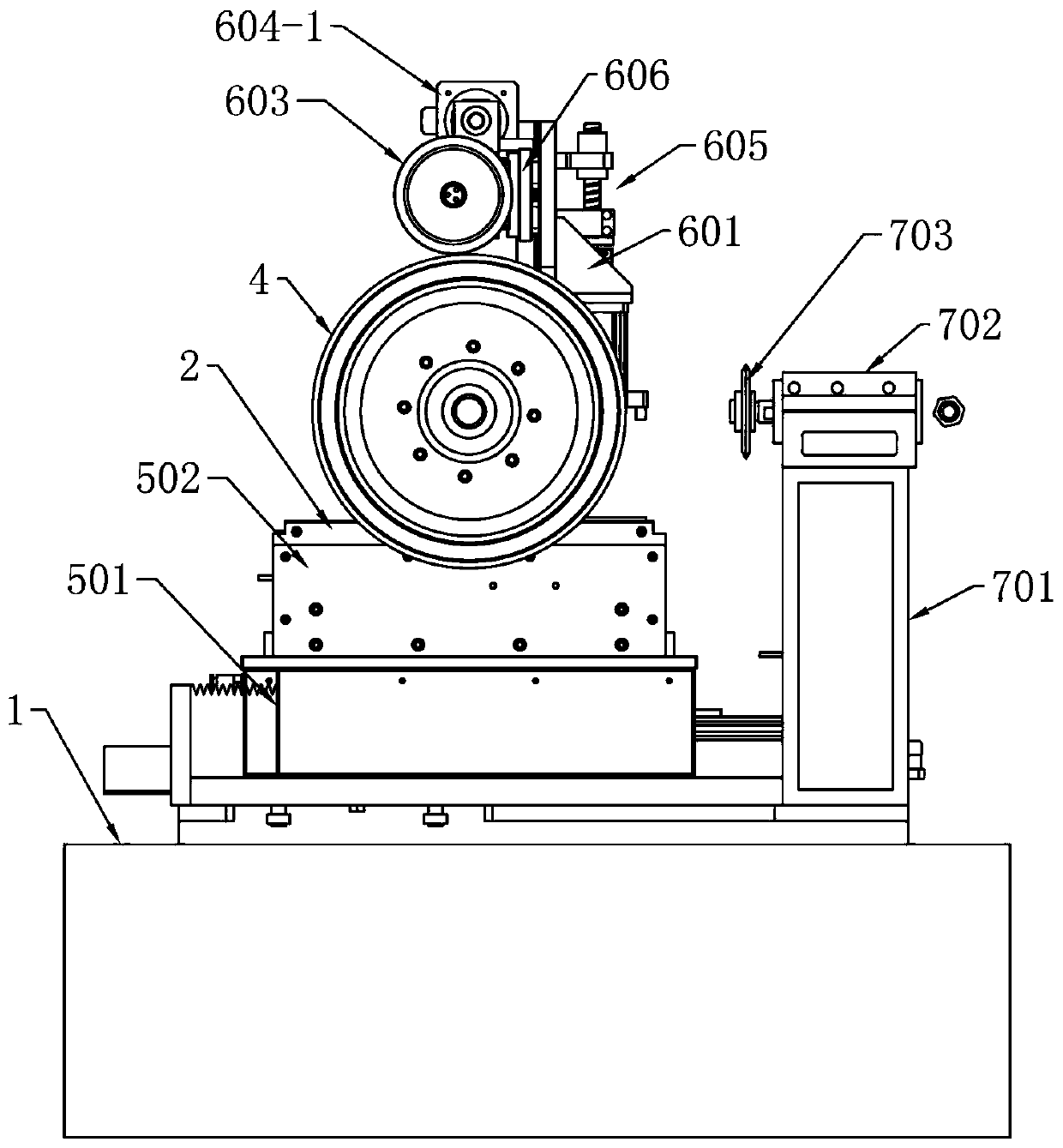

[0016] Specific Example 1: See Figure 1 to Figure 3 , in an embodiment of the present invention, a high-precision CBN grinding wheel 4 online automatic dressing device includes a machine tool platform 1, a base 2 is provided on the machine tool platform 1, a cross slide 5 and a machine tool platform are arranged below the base 2 1 sliding connection, the base 2 is provided with a grinding wheel electric spindle 3 for installing the CBN grinding wheel 4 to be trimmed, and above the grinding wheel electric spindle 3 is provided with a first sand repairing device 6 for trimming the outer contour of the CBN grinding wheel 4, so The first sand repairing device 6 is slidingly connected with the base 2, and one side of the cross slide 5 is provided with a second sand repairing device 7 for dressing the outer end surface of the CBN grinding wheel 4, and the second sand repairing device 7 is vertically fixed on the On the machine tool platform 1 and at the front end of the grinding wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com