Drum-type cleaning machine for trimming of small and medium sized castings

A drum-type, small and medium-sized technology, which is applied in the field of drum-type cleaning machinery for small and medium-sized casting repairs. It can solve the problems of waste debris mixed together, a large amount of sewage and cement sand, and the surface of castings is easy to rust. Relative range of motion, the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

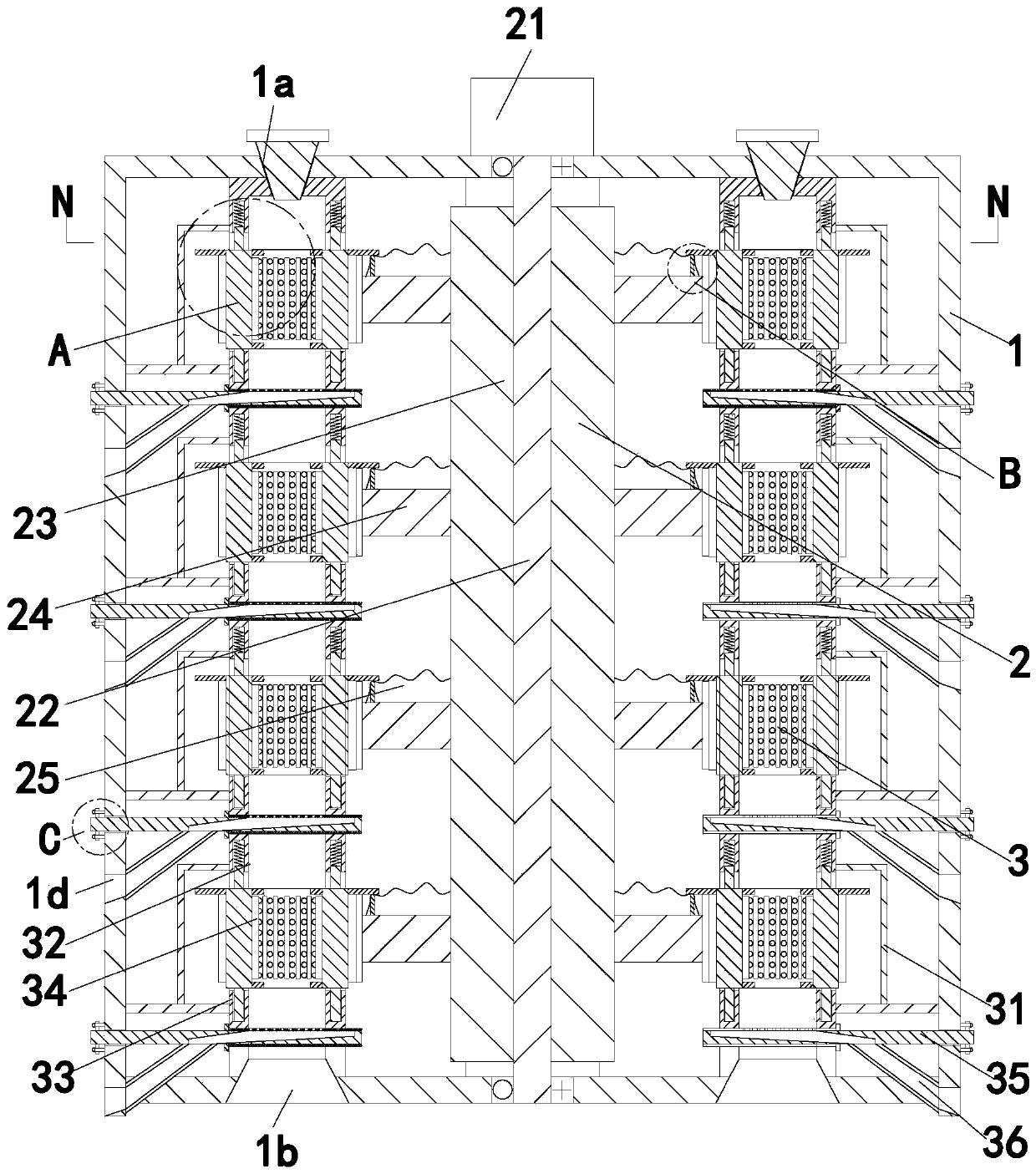

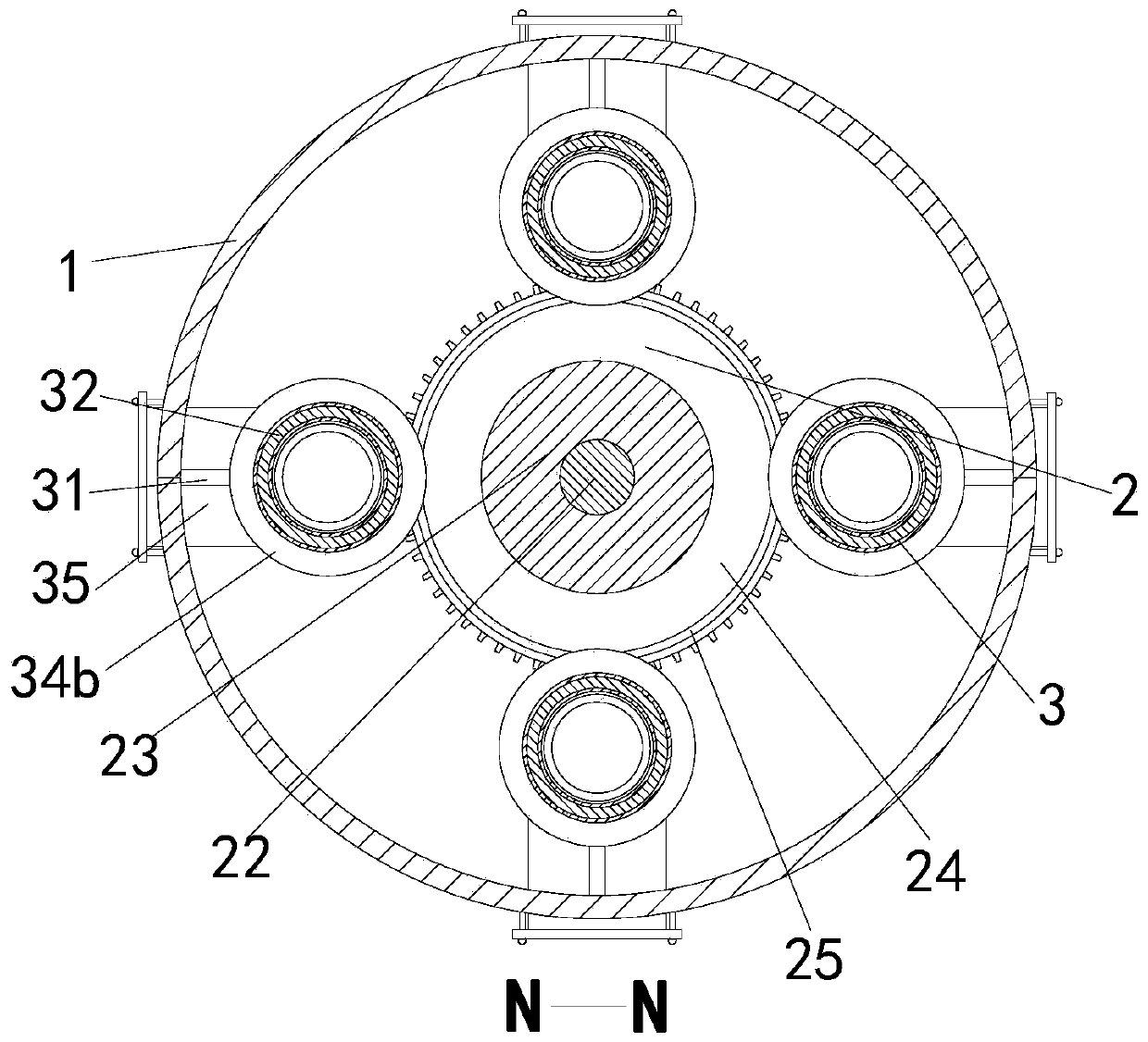

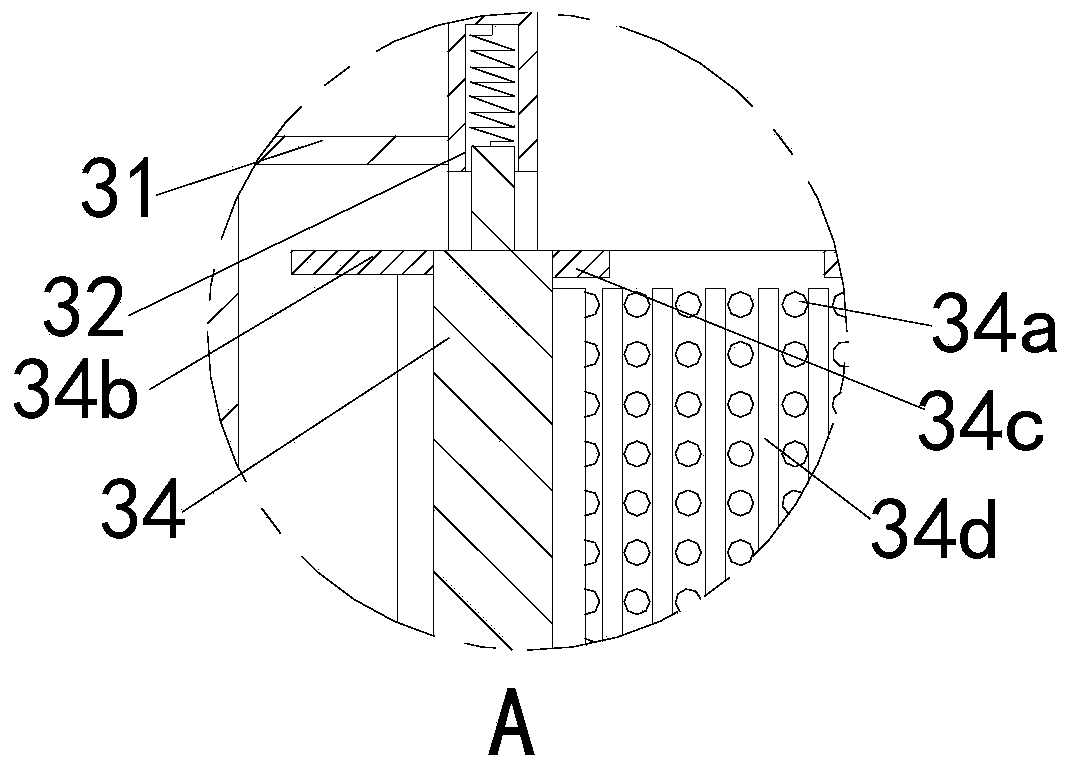

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 5 , to further elaborate the present invention.

[0027] A drum-type cleaning machine for small and medium-sized castings, including a cylinder body 1, a driving mechanism 2, and a cleaning mechanism 3. The middle part of the cylinder body 1 is equipped with a driving mechanism 2, and the outer side of the driving mechanism 2 is uniformly arranged along its circumferential direction. Mechanism 3, the cleaning mechanism 3 is installed on the inner wall of the cylinder body 1, and the upper end of the cylinder body 1 is uniformly provided with a feed port 1a along its circumferential direction, and the lower end of the cylinder body 1 is uniformly provided with a discharge port 1b along its circumferential direction. The side wall of the body 1 is uniformly provided with the installation port 1c and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com