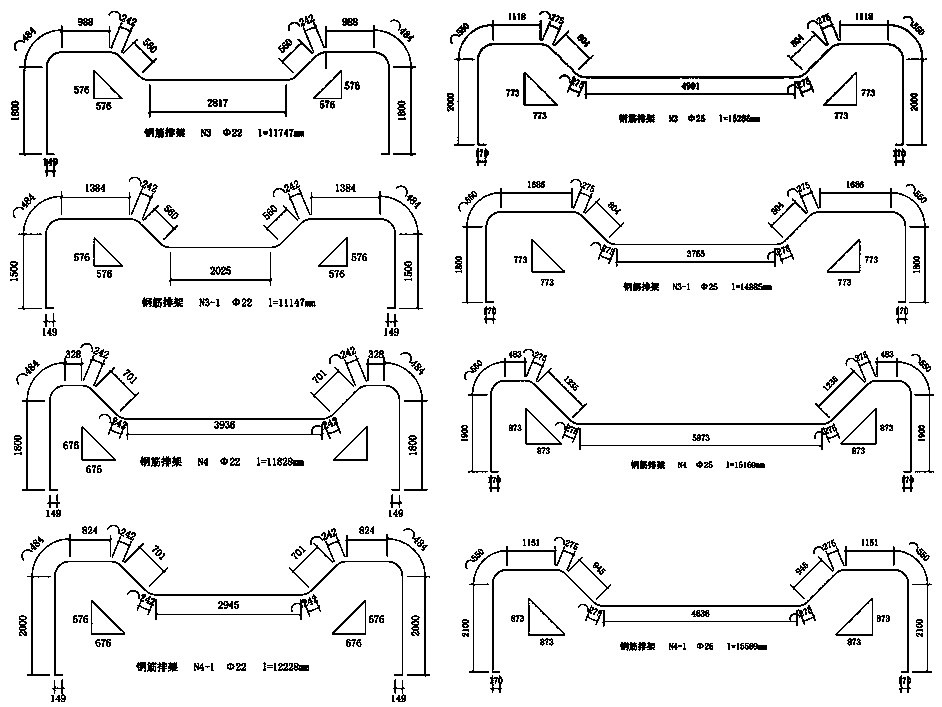

Machining device special for long and large bent-up steel bars of frame box bridge

A technology for bending steel bars and processing equipment, which is applied in the field of special processing equipment for long bending steel bars of frame box bridges, can solve the problems that the finished steel bars are difficult to meet the design requirements, the accumulated error of the bending machine is large, and the labor cost input is large, and the structural Simple, low equipment manufacturing cost, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

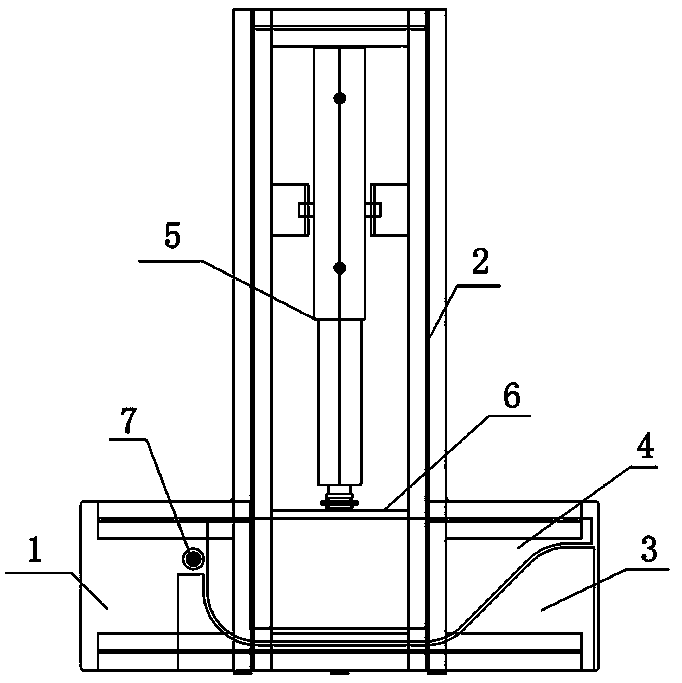

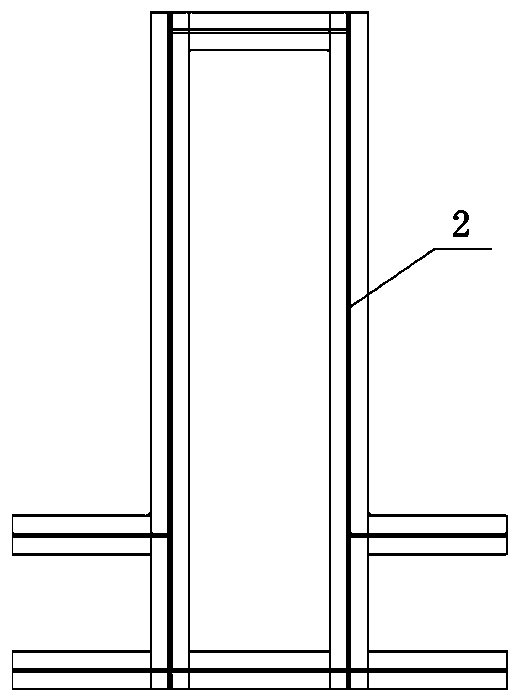

[0019] Such as figure 2 As shown, the special processing equipment for the long and bent steel bars of the frame box bridge of the present invention includes a frame 2 with an operating platform 1. During actual manufacture, the frame 2 can be welded by I-beams, and the frame after forming 2 is a T-shaped frame structure, such as image 3 As shown; the operating platform 1 is a U-shaped plate structure, and the opening is fixed inwardly on the load-bearing end of the frame 2, as Figure 4 As shown, a fixed formwork 3 is installed at the end of the operating platform 1, such as Figure 5 As shown, the operating platform 1 corresponding to the position of the fixed template 3 is provided with a movable template 4, such as Figure 6 As shown, the movable formwork 4 is driven forward and backward by the hydraulic cylinder 5 fixedly arranged on the frame 2, and the working surface between the fixed formwork 3 and the movable formwork 4 is a curved surface consistent with the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com