Preparation method of unconventional natural gas well fracturing physical simulation sample

An unconventional natural gas and physical simulation technology, applied in the field of rock sample preparation, can solve the problems of high degree of weathering, difficulty in controlling bedding planes, and inability to realize comparative research on experimental variables, achieving the effect of strong operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

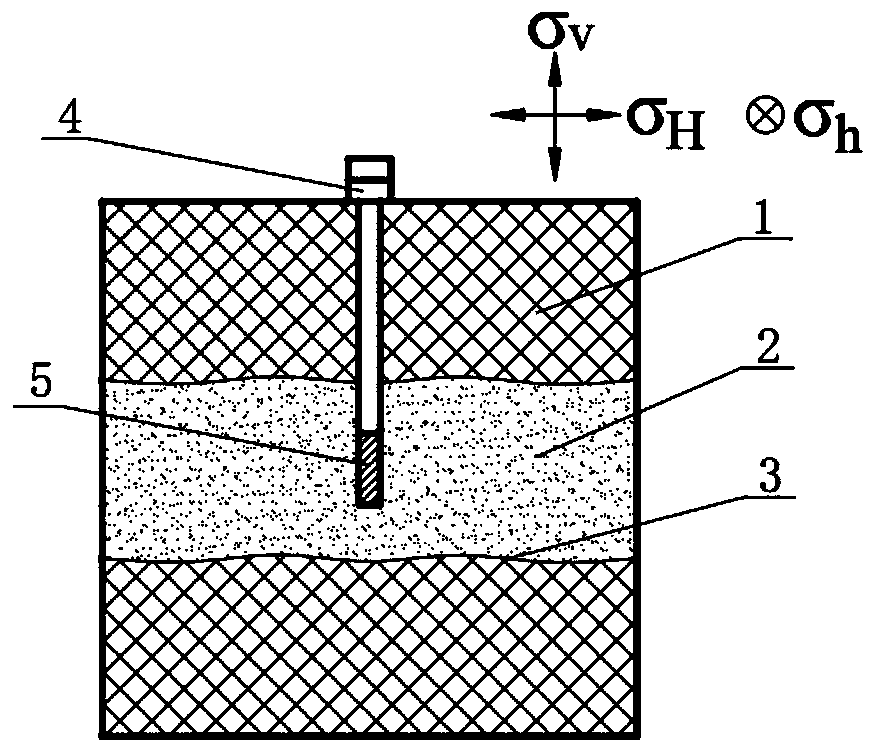

[0039] Step 1: Since the simulated object of the artificial rock core 2 in the middle layer is reservoir shale, it is first necessary to drill a reservoir shale specimen from the reservoir shale. The reservoir shale specimen is a cylinder with a size of for and

[0040]Then, the uniaxial compressive strength and tensile strength of the reservoir shale specimens were determined by using the uniaxial compressive strength test and the Brazilian splitting test, and then the cement that met the requirements of the strength label was selected. In this embodiment, the cement is Portland cement with a strength grade of 62.5R.

[0041] Step 2: Process the sandstone into two cuboid sandstone sheets 1 of the same size by hydraulic cutting, place them on both sides of the steel concrete mold, pour the mixture of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com