A method for preparing physical simulation samples for fracturing of unconventional natural gas wells

An unconventional natural gas and physical simulation technology, applied in the field of rock sample preparation, can solve the problems of difficult control of bedding planes, high degree of weathering, and difficulty in grasping the law of fracture penetration and propagation, and achieve the effect of simple structure and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the content of the invention of the present invention, the present invention will be described in detail below in conjunction with specific embodiments.

[0047] The shear test is a restricted shear test.

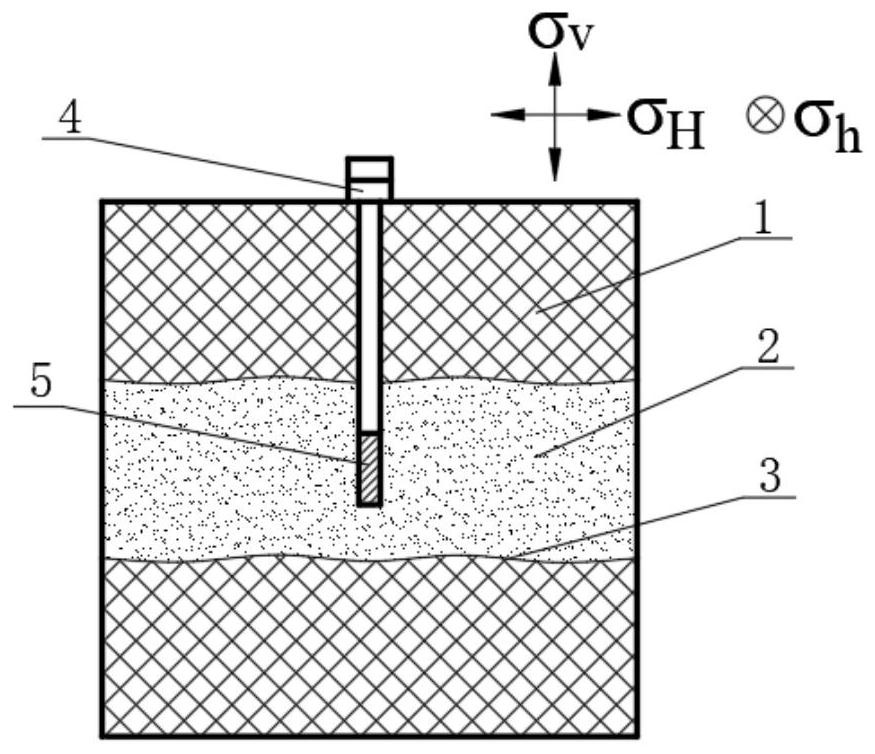

[0048] In the step 4, the simulated wellbore is drilled on the center position of the wide surface of the sandstone sheet 1. The diameter of the simulated wellbore is

[0049] In the step 4, the simulated wellbore 4 is cemented in the simulated wellbore using AB silica gel, and the cementation time is 8h.

[0050] The fracturing experiment adopts a large-scale true triaxial simulation test system. Unconventional natural gas production in simulated horizontal well fracturing

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com