Mounting structure of ultrasonic flowmeter probe

An installation structure and flowmeter technology, which is applied in the direction of measuring devices, volume measurement, flow measurement/mass flow, etc., can solve the problems of ultrasonic flowmeter measurement data error, affecting ultrasonic flowmeter data measurement, troublesome installation and disassembly, etc. To achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

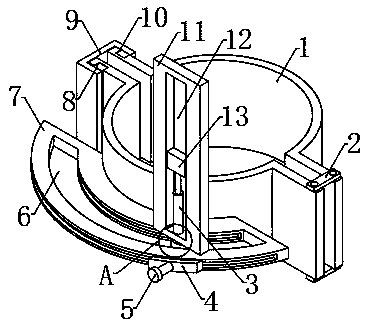

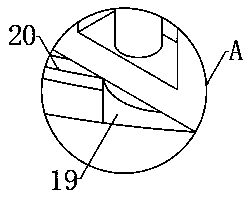

[0021] like figure 1 and image 3 As shown, an installation structure of an ultrasonic flowmeter probe includes two splints 1, one end on both sides of the two splints 1 is respectively connected to the two ends of the two fixed plates 2 through four rotating shafts, and the two splints 1 One end of one side is provided with a first chute 10, and the two sides of the inner walls of the two first chute 10 are respectively slidably connected with the two sides of the two slide plates 8, and one side of the two slide plates 8 is connected with the U-shaped plate 9 respectively. The two sides of the inner wall are fixedly connected, and the two splints 1 are set on the pipeline to be tested, and the slide plate 8 is drawn into the first chute 10, so that the splint 1 is fixed, and the probe body 18 can be fixed on the pipeline to be tested. To facilitate the installation and disassembly of the probe body 18, the middle part of one side of the splint 1 is fixed with an arc-shaped ...

Embodiment 2

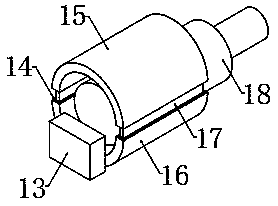

[0023] On the basis of embodiment one, refer to figure 1 and image 3 , the top of the slide bar 19 is fixedly connected to the middle part of the bottom end of the moving plate 11, and the middle part on one side of the moving plate 11 is provided with a third chute 12, and the two sides of the third chute 12 inner wall are connected with the two sides of the second slider 13 respectively. Slidingly connected, the middle part of one side of the second slider 13 is fixedly connected with the middle part of one side of the bottom plate 16, the inner wall of the bottom plate 16 is engaged with the outer wall of the probe body 18, and both sides of the top of the bottom plate 16 are provided with card slots 14. Two clamping grooves 14 are engaged and connected with two clamping plates 17 respectively, and the two clamping plates 17 are respectively fixedly arranged on both sides of the bottom end of the top plate 15, the probe body 18 is placed on the bottom plate 16, and the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com