Modular floor heater and air conditioner all-in-one machine

A modular, all-in-one technology, applied in air conditioning systems, heating methods, space heating and ventilation, etc., can solve problems affecting the heating effect of floor heating, and achieve the effect of keeping a clear mind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

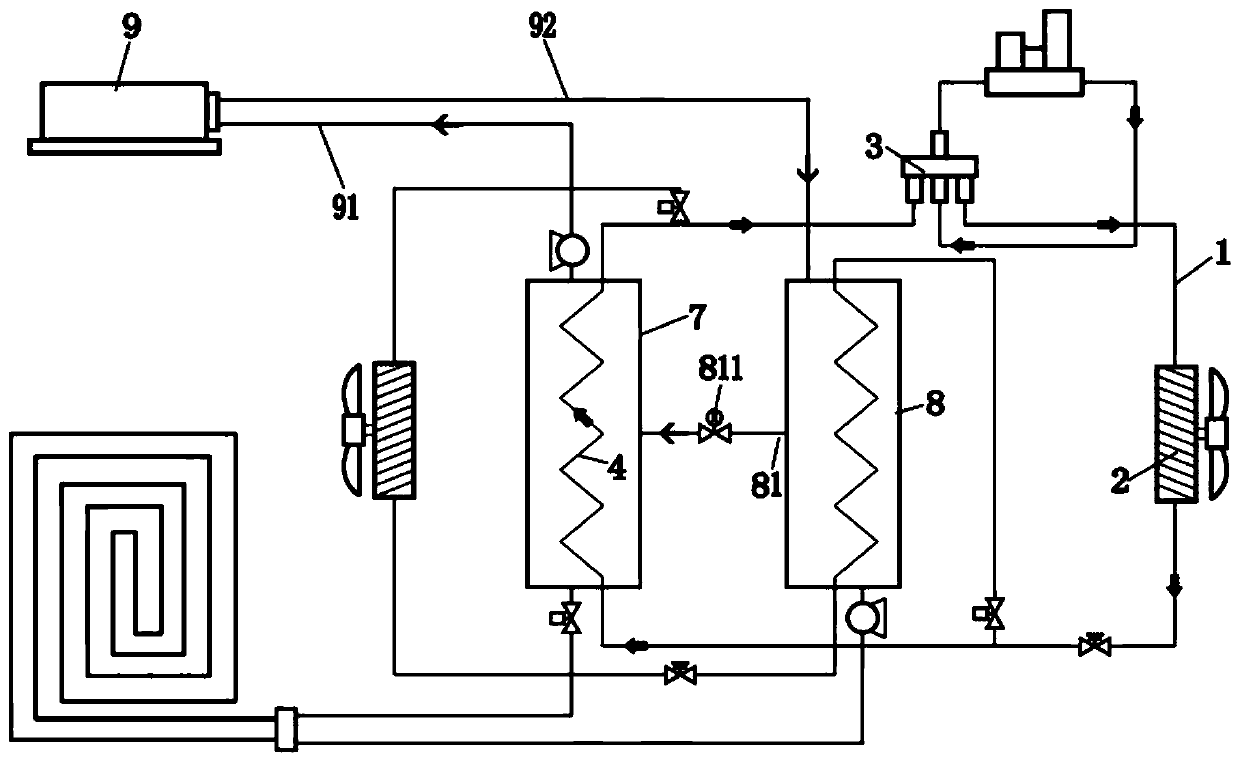

[0032] Such as figure 1 As shown, the modular floor heating and air conditioning integrated machine includes: refrigerant circulation pipeline 1, evaporator 1, 2, four-way valve 3, heat exchanger 1 4, evaporator 2 5, heat exchanger 2 6, water tank 1 7, water tank 28. Fan coil unit 9, floor heating circulation pipeline 10;

[0033] The refrigerant circulation pipeline 1 is connected with an evaporator-2, a four-way valve 3, a compressor, a heat exchanger-4, and a throttle valve, wherein the refrigerant circulation pipeline 1 is located between the four-way valve 3 and the heat exchanger-4. The part between is equipped with a refrigerant circulation pipeline;

[0034] The first branch of the refrigerant circulation pipeline is connected to the evaporator two 5, another throttle valve, and the heat exchanger two 6 in sequence, and the extended end of the first refrigerant circulation pipeline is connected to the heat exchanger one 4 and the throttle valve The refrigerant circul...

no. 2 example

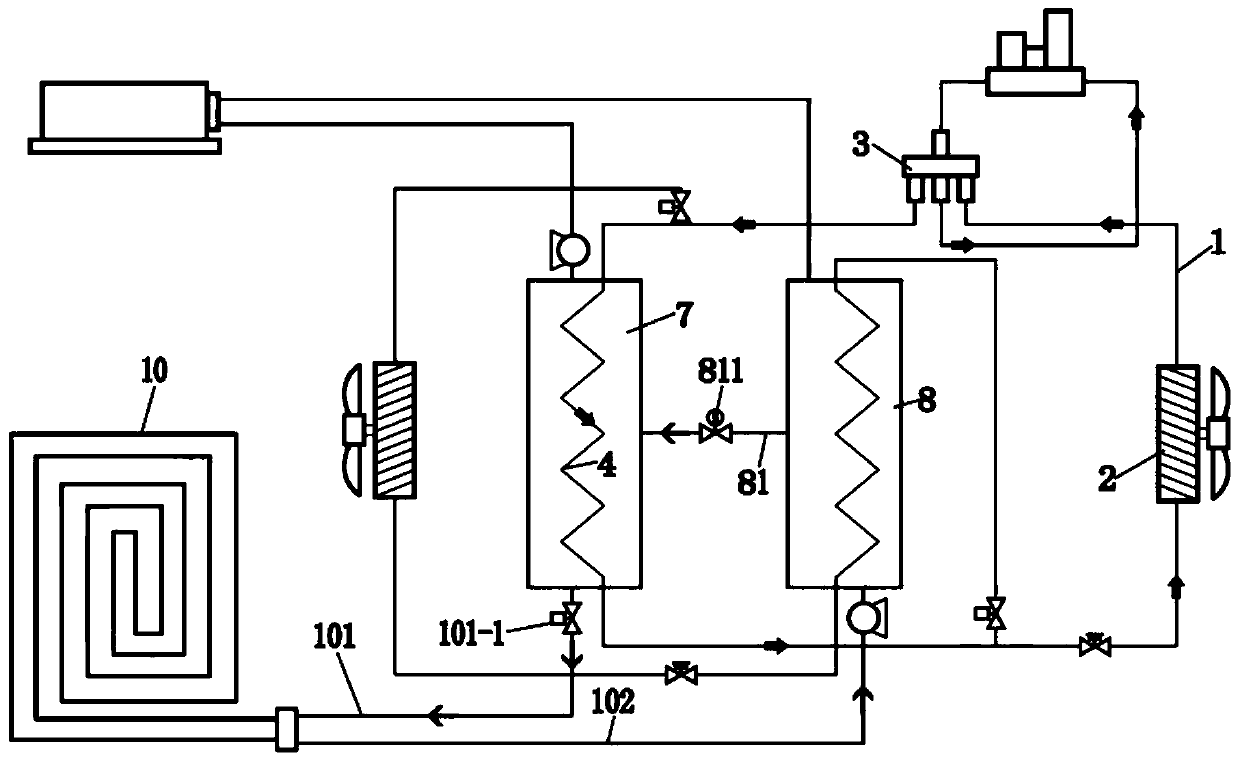

[0047] Modular floor heating and air conditioning integrated machine, including: refrigerant circulation pipeline 1, evaporator 2-1, four-way valve 3, heat exchanger 4-1, water tank 1 5-1, water tank 2 6-1, water pipe 7-1 , circulation pipeline 8-1, fan coil unit 9, floor heating circulation pipeline 10;

[0048] The refrigerant circulation pipeline 1 is sequentially connected to the evaporator 2, the four-way valve 3, the compressor, the heat exchanger 4, and the throttle valve;

[0049] Change the flow direction of the refrigerant through the four-way valve 3, so that the heat exchanger 4 can absorb heat and release heat or absorb cold and release heat;

[0050] The water tank one 5-1 accommodates the heat exchanger 4;

[0051] The first water tank 5-1 communicates with the second water tank 6-1 through the flow pipeline 7-1, and the second water tank 6-1 communicates with the evaporator 2-1 through the circulation pipeline 8-1, wherein the circulation pipeline 8-1 communic...

Embodiment approach

[0058] Preferably, as an implementable manner, a water barrier 11-1 is provided in front of the evaporator 2-1 to prevent water from overflowing when flowing along the evaporator 2-1.

[0059] The working principle of this embodiment:

[0060] The flow direction of the refrigerant is changed through the four-way valve 3 to realize separate cooling and heating of the fan coil unit 9 and the floor heating circulation pipeline 10 or joint cooling and heating. When the fan coil unit 9 needs to be turned on for cooling, the floor heating circulation pipeline 10 is used for heating mode, such as Figure 10 As shown, the circulating water pump 1 8-11 is turned on, the water in the water tank 2 6-1 flows into the evaporator 2-1 along the circulating pipeline 8-1, exchanges heat with the evaporator 2-1, cools down, and flows into the water tank again In the second 6-1, the heat exchanger 4-1 heats the water in the water tank one 5-1 at the same time, the three-way valve 91-11 closes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com