A water injection packer

A packer and faucet technology, applied in the direction of sealing/packing, cleaning equipment, wellbore/well components, etc., can solve the problems of inability to realize subdivided water injection in multiple sections, cumbersome deployment process, and long deployment cycle. Achieve the effects of shortening the debugging cycle, simplifying the deployment process, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

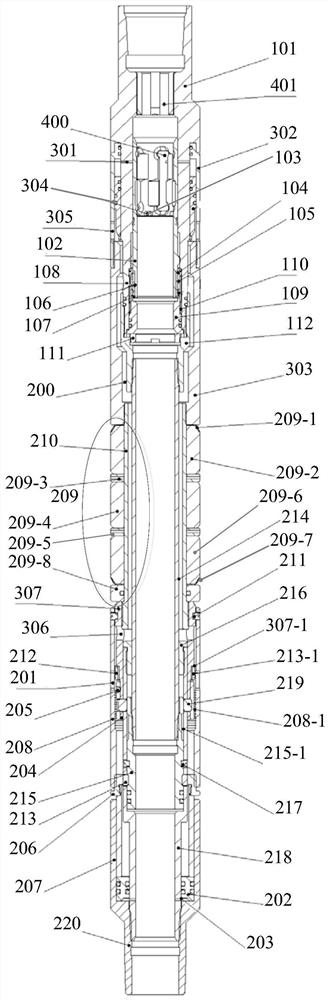

[0087] attached figure 1 A schematic diagram of a water injection packer provided for the embodiment of the present invention, as attached figure 1 As shown, the water injection packer includes: a water distribution mechanism and a seating and unsealing mechanism;

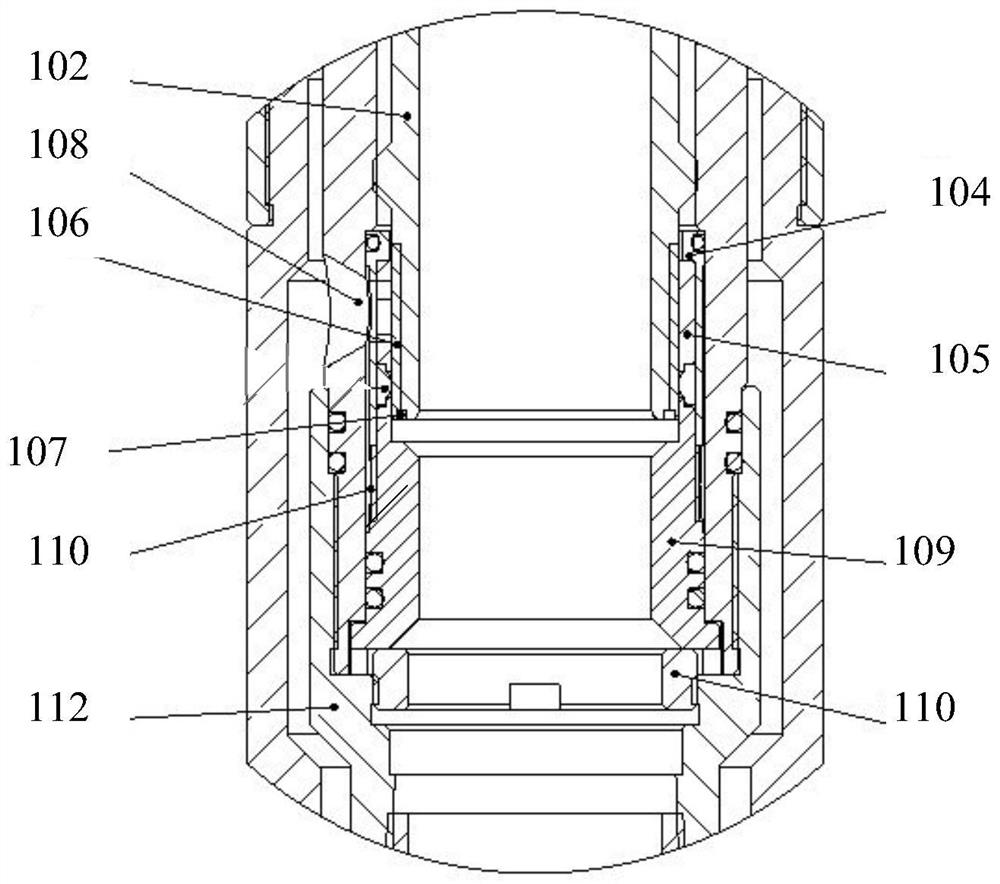

[0088] The water distribution mechanism includes: an upper joint 101, a working cylinder 102, a water outlet 103, a fixed water nozzle 104, a fixed water nozzle lining 105, a movable water nozzle outer lining 106, a water nozzle outer lining collar 107 and a water outlet 108;

[0089] Wherein, the working cylinder 102 is arranged at the lower end inside the upper joint 101, and the working cylinder 102 can move up and down in the vertical direction,

[0090] The water hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com