Gradual-changing mortar spraying device for spray coating

A spraying device and gradient technology, applied in the field of gradient mortar spraying devices for spraying, can solve the problems of poor spraying effect, uneven spraying, thick mortar coating, etc., and achieve safe and convenient use, avoid random placement, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

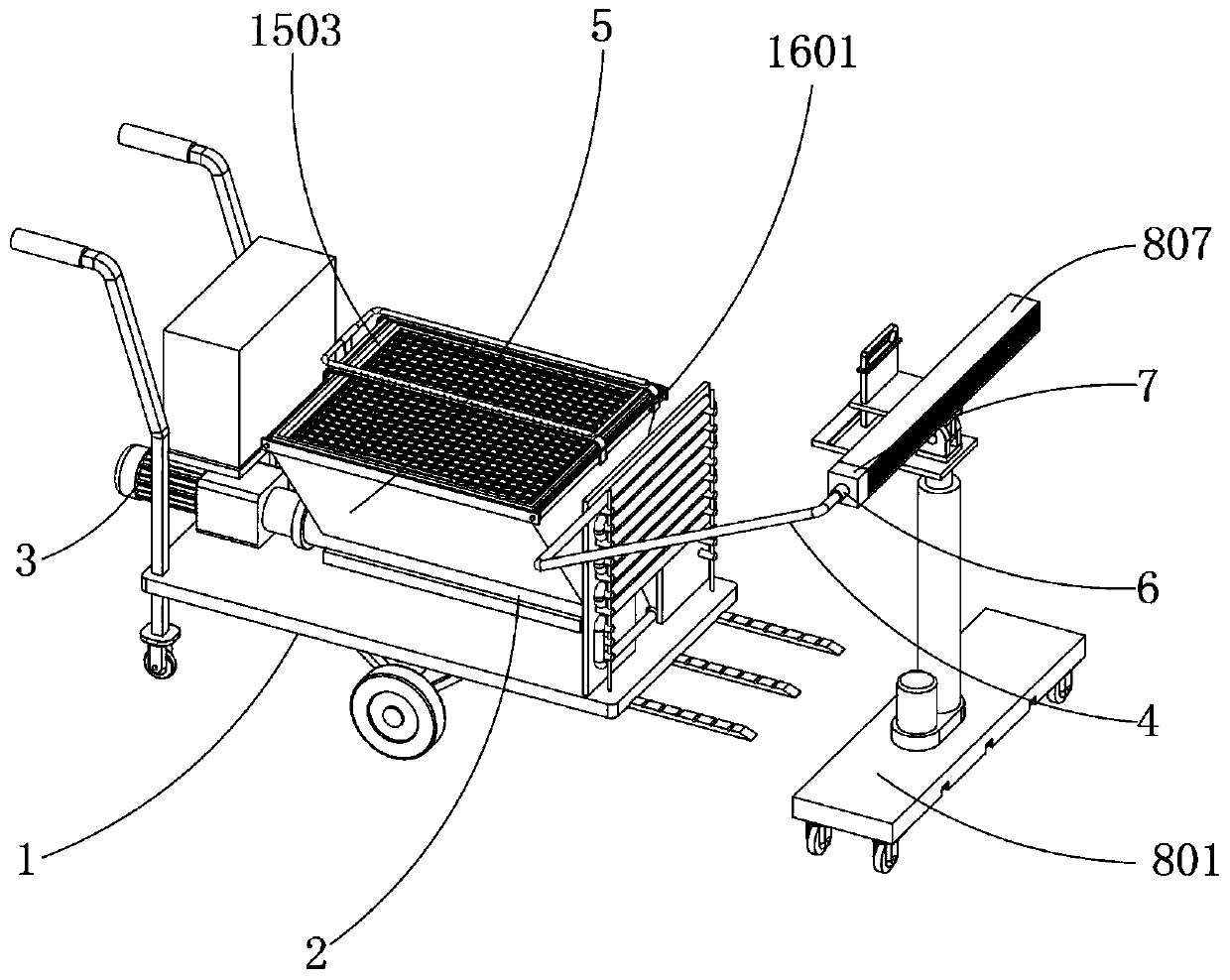

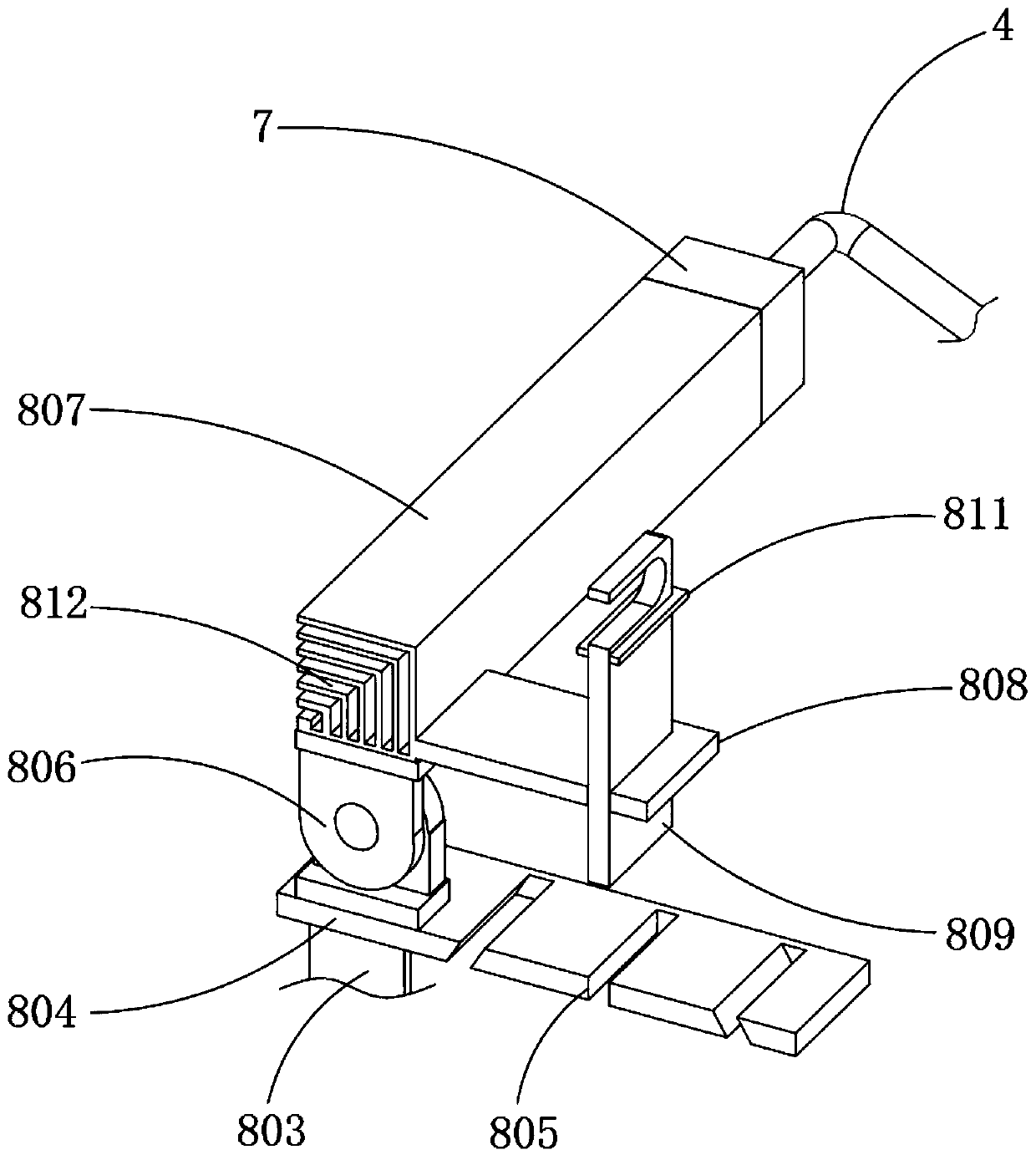

[0048] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a gradual change mortar spraying device for spraying, comprising a spraying machine frame 1, a screw pump 2, a motor 3 and a feed bin 5, after starting the motor 3, the bottom of the feed bin 5 The mortar is in contact with the middle part of the screw pump 2, and enters between the pump body and the screw blade of the screw pump 2, and the screw shaft in the screw pump 2 is driven by the motor 3 to rotate, because a sealed cavity is formed between the screw blade and the screw pump 2 body, Every time the screw rotates once, the mortar in the sealing cavity is pushed forward by one pitch. With the continuous rotation of the screw, the mortar is pressed from one sealing cavity to the other in a spiral manner, and finally extruded out of the screw pump 2 pump body, and then completes For the purpose of spraying outward, a screw pump 2 is installed on the top of the sprayer frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com