Method and machine for manufacturing a fibrous material web

A fiber material and machine technology, applied in the field of pressing devices, can solve the problems of high energy consumption, production speed and output limitation, and achieve the effect of improving residence time, reliable and stable operation, and optimizing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

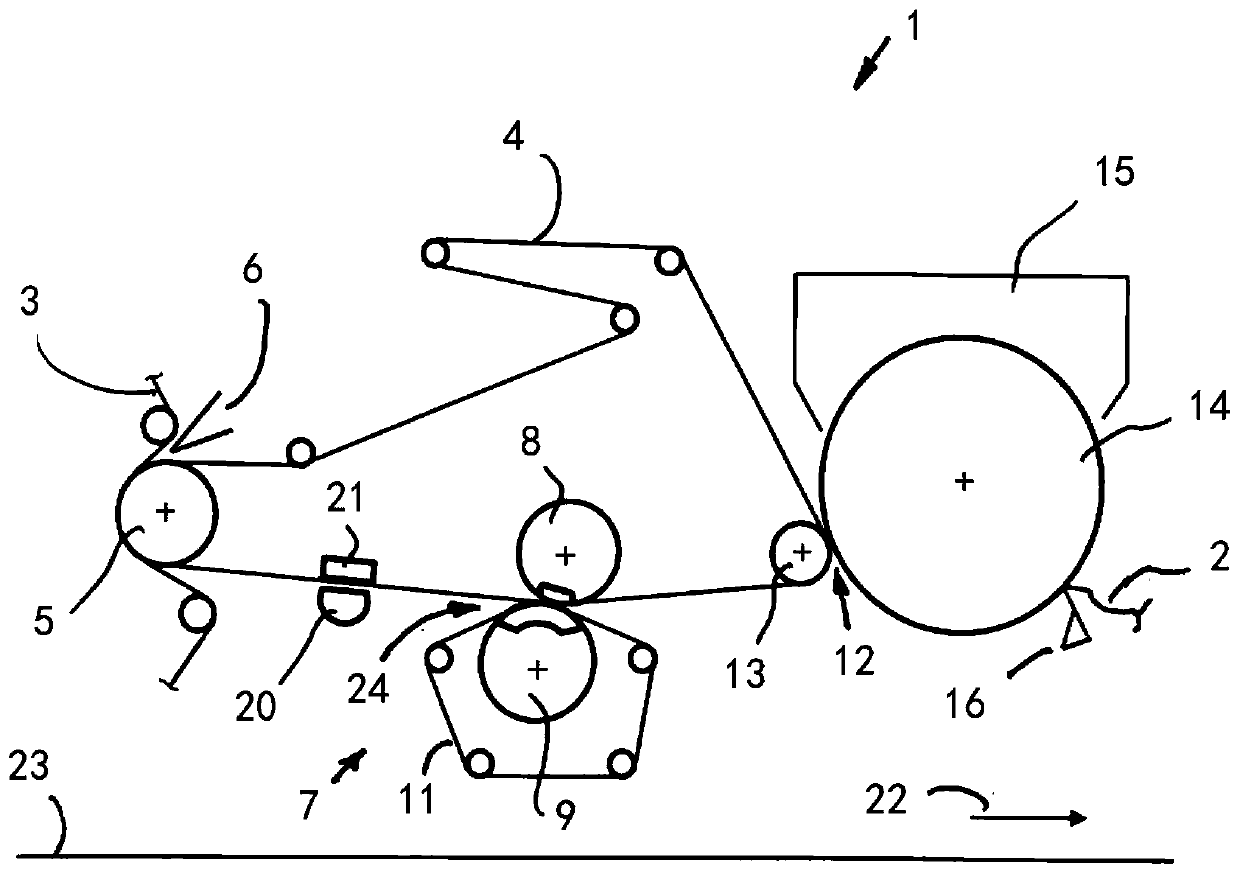

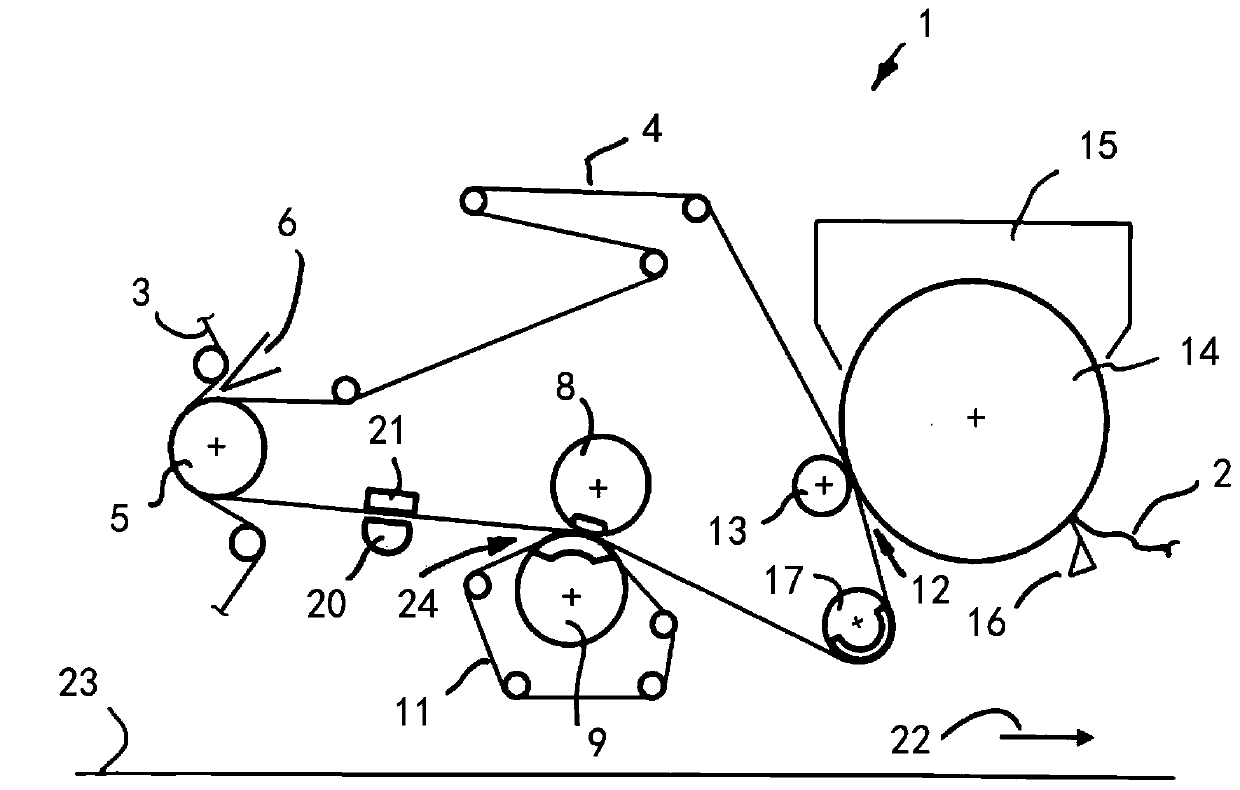

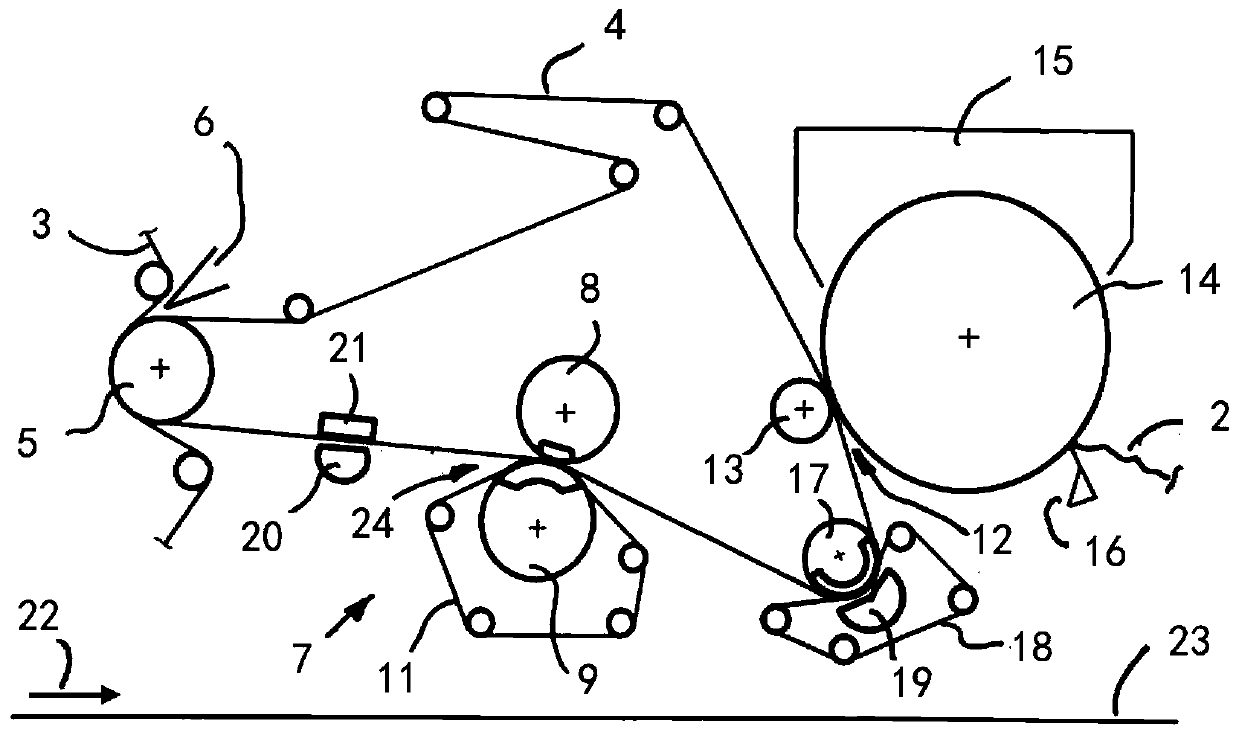

[0032] figure 1A simplified schematic representation of a first embodiment of the machine 1 according to the invention is shown. A machine 1 for producing a fibrous web 2, in this case a tissue web 2, comprises a forming area with a forming roll 5 and an inner belt 4 which at least partially encloses the forming roll together with the outer belt 3 5. The headbox 6 introduces the fiber suspension between the belts 3, 4 (ie the inner belt 3 and the outer belt 4). In order to form the tissue web 2, in the region of the forming roll 5, the fiber suspension is dewatered mainly in the common wrapping region of the belts 3, 4 and is guided, supported on the inner belt 4, to the subsequent press 7 and through the pressing device 7 . The press device 7 comprises in this example an upper press roll 8 and a lower counter roll 9 which cooperate to create a press nip 24 for further dewatering of the tissue web 2 . Counter roll 9 and press roll 8 can also be arranged inversely. The cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com