Reactive single-component polyurethane root-puncture-resistant waterproof coating material and preparation method thereof

A waterproof coating, root puncture-resistant technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to ensure the uniformity of dispersion, improve stability and durability, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

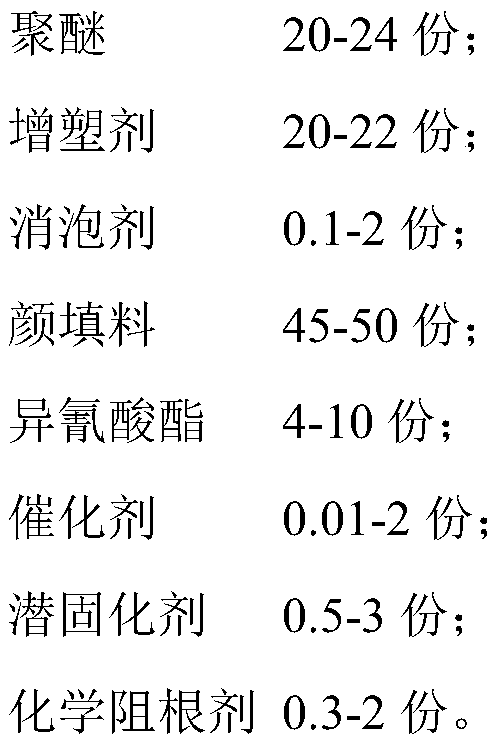

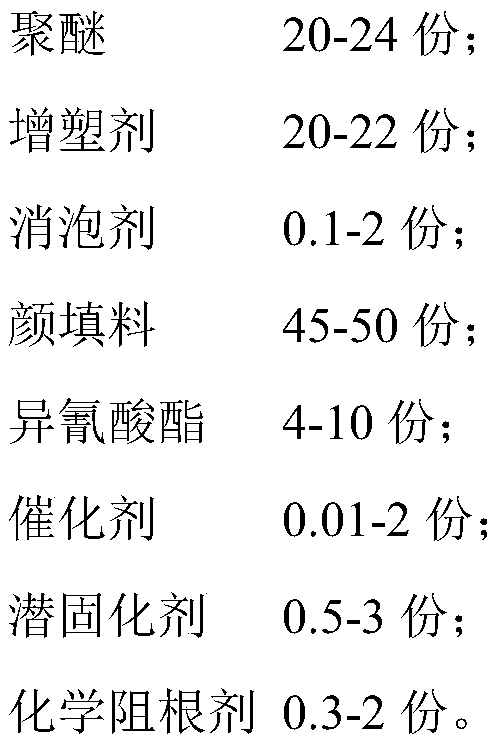

Method used

Image

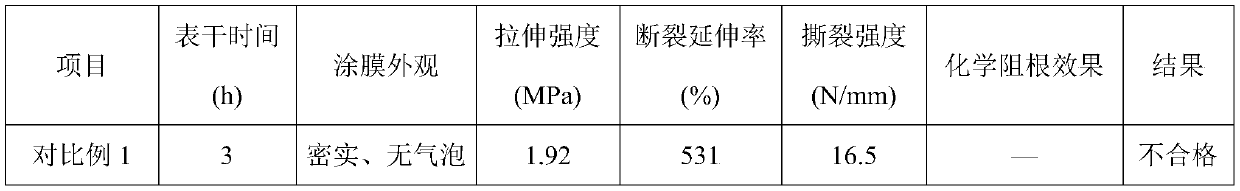

Examples

Embodiment 1

[0035] A reactive single-component polyurethane root puncture-resistant waterproof coating, including the following raw material components: 12 parts of amino-terminated polyether (D2000), 12 parts of polyether trihydric alcohol (330N), 5 parts of isocyanate (TDI), chlorinated 20 parts of paraffin, 47 parts of pigments and fillers (heavy calcium, talcum powder), 0.1 parts of organic tin catalyst (CT-11), 1.8 parts of latent curing agent (JW505), chemical root inhibitor ((R)-2-(4- Chloro-2-methylphenoxy) propionate-2-hydroxypropyl) 0.5 parts, silicone defoamer (AP001) 0.2 parts, dispersant 0.05 parts, mineral spirits 3 parts.

[0036] Specific preparation steps: add 12 parts of amino-terminated polyether (D2000), 12 parts of polyether trihydric alcohol (330N), 20 parts of chlorinated paraffin, 0.2 parts of silicone defoamer (AP001), and Filler (heavy calcium, talcum powder) 47 parts, after high-speed dispersion evenly, heat up to 100-110°C under stirring, and dehydrate for abou...

Embodiment 2

[0038] A reactive single-component polyurethane root puncture-resistant waterproof coating, including the following raw material components: 12 parts of amino-terminated polyether (D2000), 12 parts of polyether trihydric alcohol (330N), 5 parts of isocyanate (TDI), chlorinated 20 parts of paraffin, 47 parts of pigments and fillers (heavy calcium, talcum powder), 0.1 parts of organic tin catalyst (CT-11), 1.8 parts of latent curing agent (JW505), chemical root inhibitor ((R)-2-(4- Chloro-2-methylphenoxy)propionic acid-2-hydroxypropyl ester) 1 part, silicone defoamer (AP001) 0.2 part, dispersant 0.05 part, mineral spirits 3 parts.

[0039] The specific preparation steps are: add 12 parts of amino-terminated polyether (D2000), 12 parts of polyether trihydric alcohol (330N), 20 parts of chlorinated paraffin, 0.2 part of silicone defoamer (AP001) into the reaction vessel, 47 parts of pigments and fillers (heavy calcium, talcum powder), after high-speed dispersion, heat up to 100-11...

Embodiment 3

[0041] A reactive single-component polyurethane root puncture-resistant waterproof coating, including the following raw materials: 12 parts of amino-terminated polyether (D2000), 12 parts of polyether trihydric alcohol (330N), 4 parts of isocyanate (TDI), chlorinated 20 parts of paraffin, 47 parts of pigments and fillers (heavy calcium, talcum powder), 0.1 parts of organic tin catalyst (CT-11), 1.8 parts of latent curing agent (JW505), chemical root inhibitor ((R)-2-(4- Mixture of 2,3-dihydroxypropyl chloro-2-methylphenoxy)propionate and 1,3-bis(R)-2-(4-chloro-2-methylphenoxy)propionate) 0.5 parts, silicone defoamer (AP001) 0.2 parts, dispersant 0.05 parts, mineral spirits 3 parts.

[0042] The specific preparation steps are: add 12 parts of amino-terminated polyether (D2000), 12 parts of polyether trihydric alcohol (330N), 20 parts of chlorinated paraffin, 0.2 part of silicone defoamer (AP001) into the reaction vessel, 47 parts of pigments and fillers (heavy calcium, talcum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com