Halogen-free flame-retardant resin and preparation method thereof

A technology of flame retardant resin and flame retardant, which is applied in the field of halogen-free flame retardant polymers, which can solve the problems of personal injury, circuit short circuit, and formation of ashes, etc., and achieve improved flame retardancy, enhanced mechanical strength, and good flame retardant effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

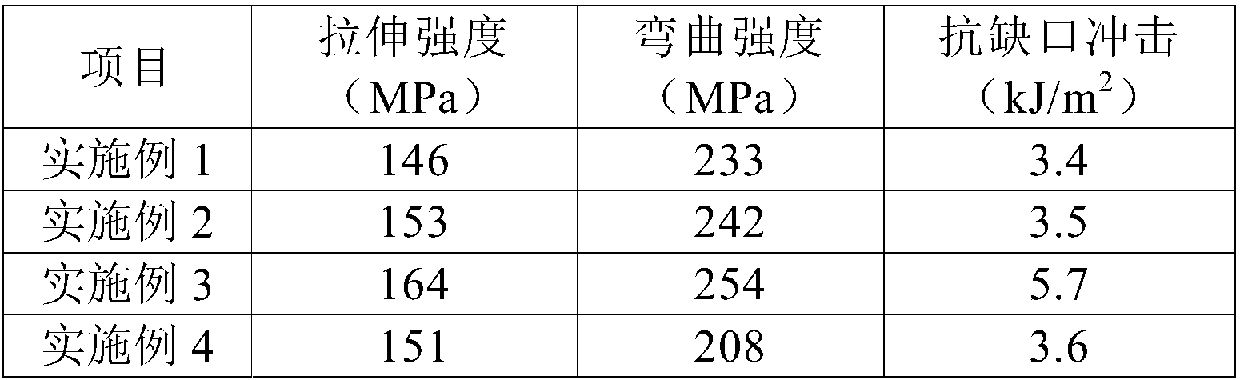

Examples

Embodiment 1

[0036] The halogen-free flame retardant resin of this embodiment includes the following components in parts by weight:

[0037] Polyamide PA56: 100 parts

[0038] Aluminum hypophosphite: 20 parts

[0039] Fiberglass: 33 parts

[0040] WAX-E: 0.3 parts

[0041] WAX-C: 0.6 parts

[0042] Antioxidant 1010: 0.4 parts

[0043] The preparation method of the halogen-free flame retardant resin of the present embodiment comprises the following steps:

[0044] 1) prepare materials according to the above ratio;

[0045] 2) Mix PA56, aluminum hypophosphite, WAX-E, WAX-C and antioxidant 1010 to obtain a premix;

[0046] 3) Use a twin-screw extruder to blend and melt the premix, and while blending and melting, use a feeder to forcibly feed the glass fibers into the premix, and after 5 minutes, extrude through a twin-screw The machine extruded strands, cooled the strands to below the melting point of PA56 with water as the cooling medium, and cut and granulated to obtain the halogen-f...

Embodiment 2

[0054] The halogen-free flame retardant resin of this embodiment includes the following components in parts by weight:

[0055] Polyamide PA56: 100 parts

[0056] Aluminum hypophosphite: 15 parts

[0057] Fiberglass: 33 parts

[0058] WAX-E: 0.3 parts

[0059] WAX-C: 0.6 parts

[0060] Antioxidant 1098: 0.2 parts

[0061] The preparation method of the halogen-free flame retardant resin of the present embodiment comprises the following steps:

[0062] 1) prepare materials according to the above ratio;

[0063] 2) Mix PA56, aluminum hypophosphite, WAX-E, WAX-C and antioxidant 1098 to obtain a premix;

[0064] 3) Use a twin-screw extruder to blend and melt the premix, and while blending and melting, use a feeder to forcibly feed the glass fibers into the premix, and after 5 minutes, extrude through a twin-screw The machine extruded strands, cooled the strands to below the melting point of PA56 with water as the cooling medium, and cut and granulated to obtain the halogen-f...

Embodiment 3

[0072] The halogen-free flame retardant resin of this embodiment includes the following components in parts by weight:

[0073] Polyamide PA56: 100 parts

[0074] Aluminum hypophosphite: 10 parts

[0075] Fiberglass: 33 parts

[0076] WAX-E: 0.3 parts

[0077] WAX-C: 0.6 parts

[0078] Antioxidant 1098: 0.2 parts

[0079] The preparation method of the halogen-free flame retardant resin of the present embodiment comprises the following steps:

[0080] 1) prepare materials according to the above ratio;

[0081] 2) Mix PA56, aluminum hypophosphite, WAX-E, WAX-C and antioxidant 1098 to obtain a premix;

[0082] 3) Use a twin-screw extruder to blend and melt the premix, and while blending and melting, use a feeder to forcibly feed the glass fibers into the premix, and after 5 minutes, extrude through a twin-screw The machine extruded strands, cooled the strands to below the melting point of PA56 with water as the cooling medium, and cut and granulated to obtain the halogen-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com