Color mixing device for graphic design

A technology of color grading device and graphic design, applied in decorative arts, painting tools, etc., can solve the problems of inaccurate dosage, ideal color chromatic aberration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

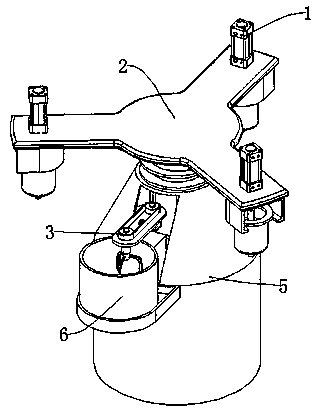

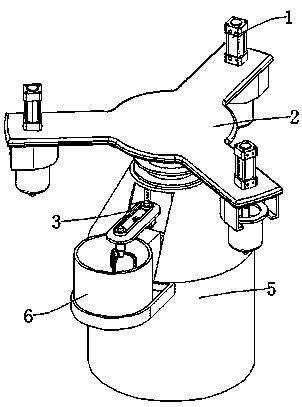

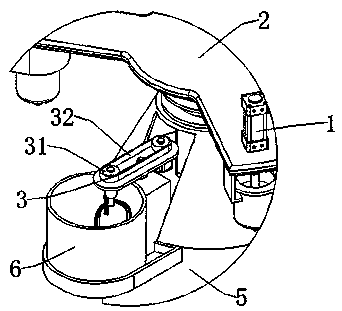

[0031]Described transmission mechanism 3 comprises belt 31, belt pulley 32, and belt pulley 32 is connected on stirring motor 25 rotating parts and stirring shaft 26 upper ends by key, belt pulley 32 outside is provided with belt 31, utilizes the transmission of belt 31 and belt pulley 32 to , mix the three kinds of pigments mixed together uniformly; the support mechanism 2 includes a first support frame 21, a rotating seat 22, a refueling motor 23, a second support frame 24, a stirring motor 25, a stirring shaft 26, a second electric motor Telescopic rod 27, the lower end of the first support frame 21 is connected to the top of the rotating seat 22 by bolts, the bottom of the rotating seat 22 is connected to the top of the cabinet 5 by bolts, the refueling motor 23 is connected to the top side of the cabinet 5 by bolts, and the second electric telescopic rod 27 The fixed part is connected to the chassis 5 by bolts, the second support frame 24 is connected to the telescopic par...

Embodiment 2

[0034] Such as figure 2 and Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the transmission mechanism 3 includes a sprocket 311 and a chain 312. The sprocket 311 is connected to the rotating part of the stirring motor 25 and the upper end of the stirring shaft 26 by a key, and a chain is arranged on the outside of the sprocket 311. 312, use the sprocket 311 and the transmission of the sprocket 311 to uniformly mix the three kinds of pigments mixed together.

[0035] see Figure 9 In the present invention, a specially designed controller device is adopted, the controller includes a chip IC, and the first pin of the chip is respectively connected to the cathode of the diode D7, the cathode of the diode D8 and the signal input terminal V1; the first pin of the chip IC The two pins are respectively connected to one end of the resistor R2 and the anode of the diode D7; the other end of the resistor R2 is connected to one end of the capacitor C1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com