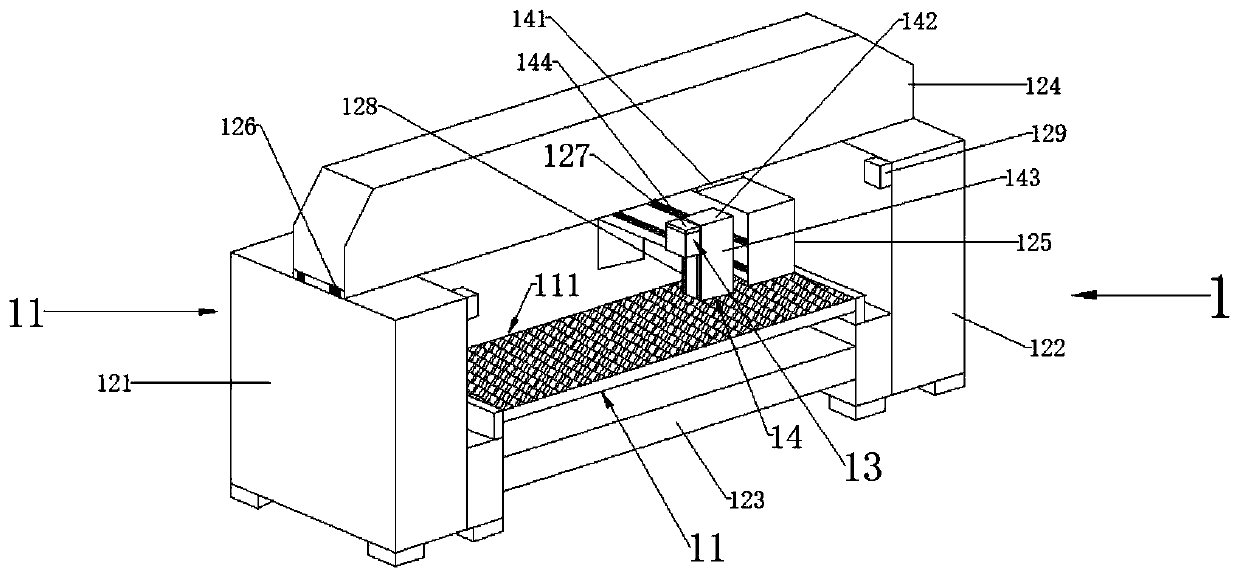

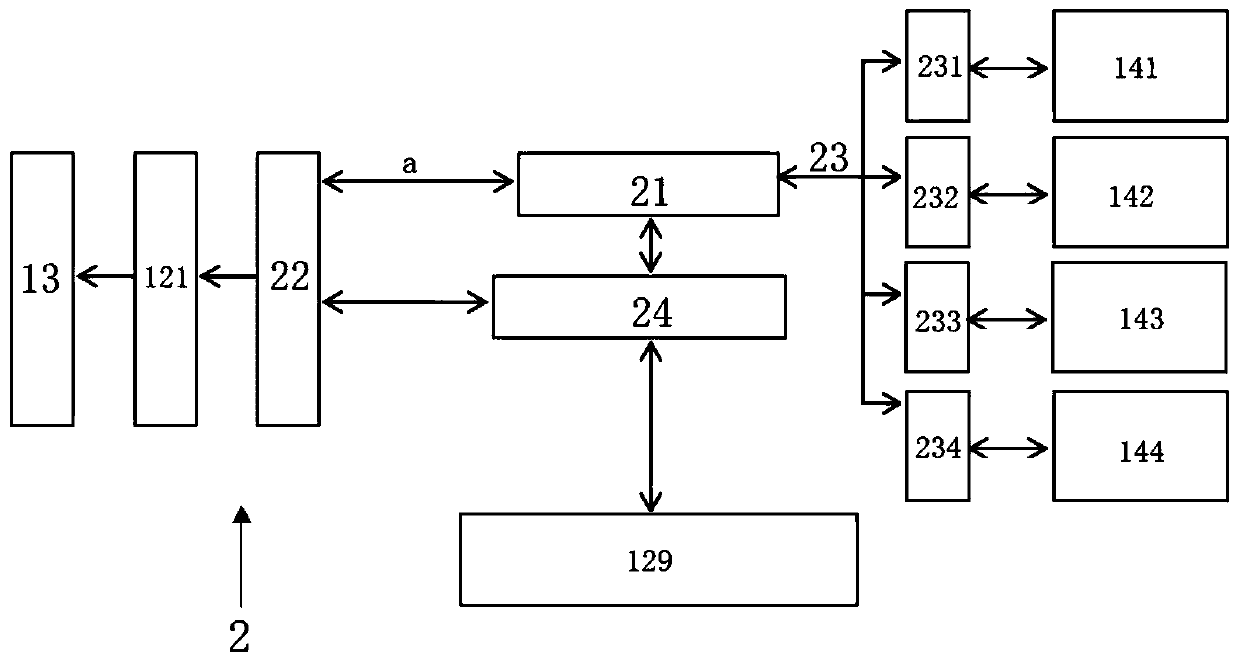

Intelligent optical fiber laser cutting system and application method thereof

A technology of laser cutting and intelligent optical fiber, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of improving the intelligent control system of optical fiber laser cutting machine, etc., so as to improve the level of perception, ensure safety, and have good application prospects wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The application method of the intelligent fiber laser cutting system described in the present invention includes the following steps in sequence:

[0046] (1) Power on, and after power on, the electrical control part (2) automatically runs the origin positioning program, finds the positive and negative of each axis and the origin limit, and then fixes the workpiece to be processed on the processing platform (11);

[0047] (2) Perform a focus search operation on the workpiece through the servo motion control mechanism (23);

[0048] (3) Perform positioning operations on three points on the boundary of the workpiece that are not on a straight line to determine the boundary of the workpiece;

[0049] (4) Import the graphics to be processed, and convert the DXF format at the same time, and click the start processing on the operation interface of the industrial computer (22).

[0050] The application method of the intelligent optical fiber laser cutting system disclosed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com