A high-pressure casting process for a non-welded axial flow fan

A high-pressure casting and axial flow fan technology, which is applied in the field of high-pressure casting technology, can solve the problems of low efficiency of performance parameters, heavy weight of low-pressure casting impellers, and lack of market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

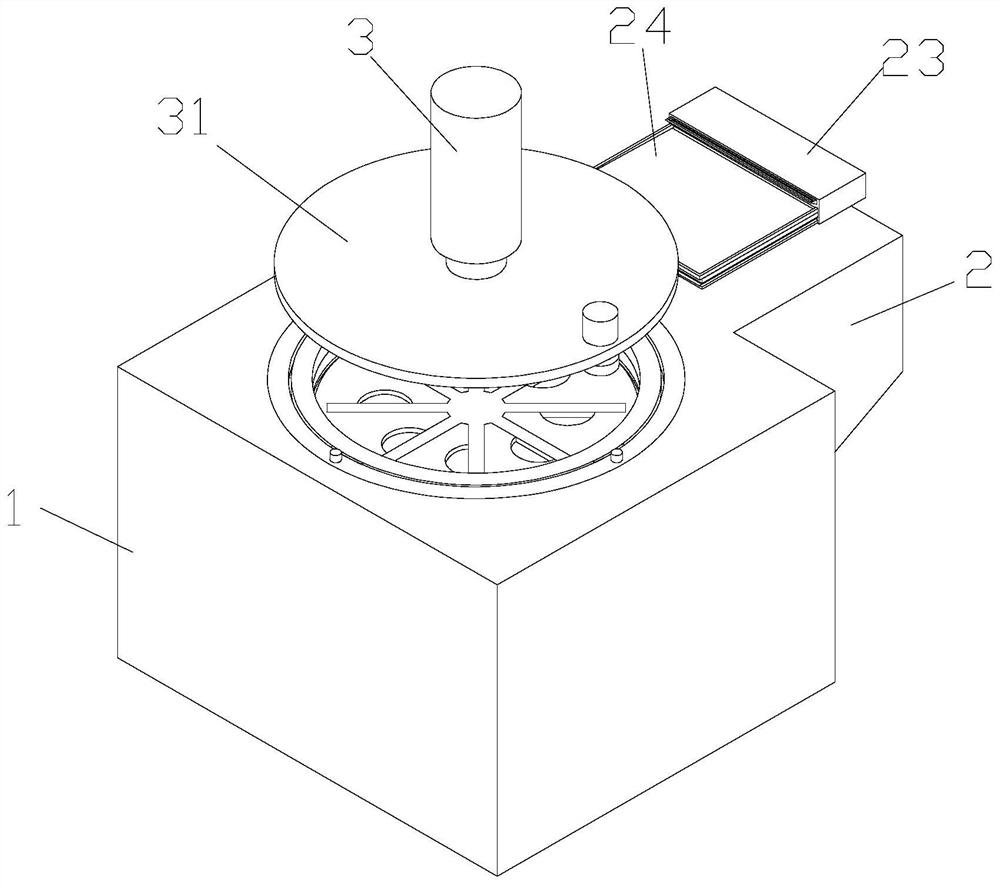

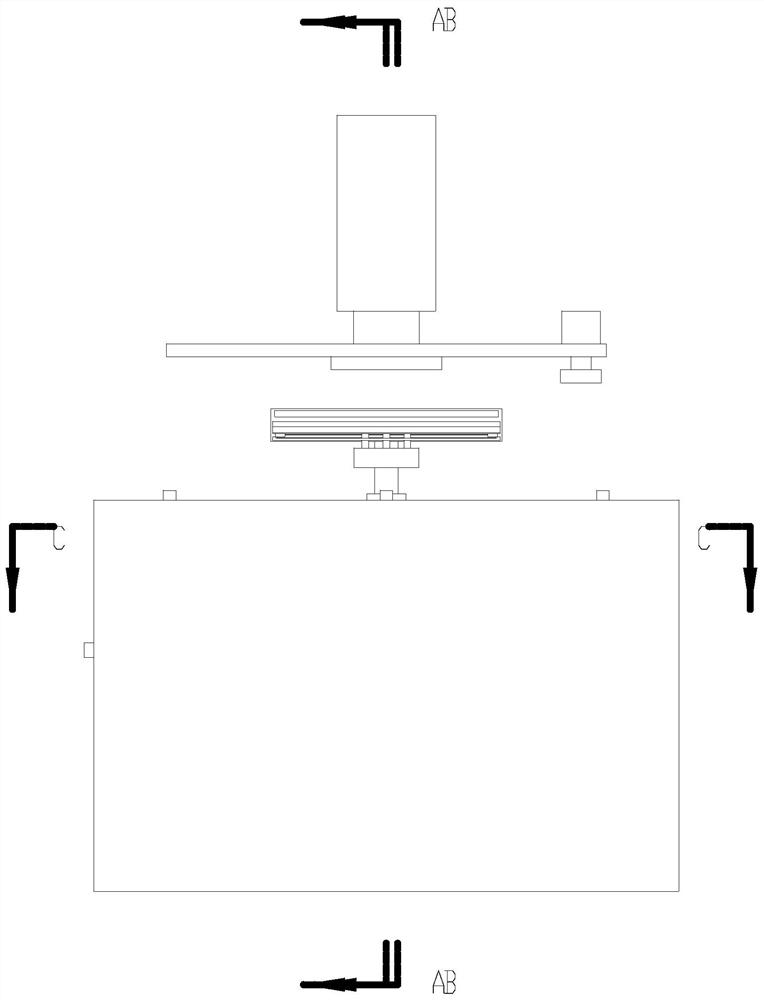

Image

Examples

Embodiment 1

[0037] A high-pressure casting process for a non-welded axial flow fan, specifically a high-pressure casting process for an impeller, including: a. Design and manufacture of a casting mold: according to the shape of the impeller, the shape of the casting mold is designed to complete the manufacture of a cone; b. The installation of the casting mold And test: put the mold into the casting machine, and test the performance index of the mold; c. Pretreatment of the mold: after preheating the mold, spray paint on the inner wall of the mold; d. With casting: after the upper and lower molds of the mold are combined, the molten metal is injected into the mold; e. Injection and cooling: The injection pressure is reasonably controlled to fill the entire mold with metal, and then the mold is cooled. Processing to make the castings rapidly formed; f. Open the mold and take out the parts: after the molding is completed, the upper and lower molds are opened, and the formed castings are dire...

Embodiment 2

[0063] A high-pressure casting process for a non-welded axial flow fan, specifically a high-pressure casting process for an impeller, including: a. Design and manufacture of a casting mold: according to the shape of the impeller, the shape of the casting mold is designed to complete the manufacture of a cone; b. The installation of the casting mold And test: put the mold into the casting machine, and test the performance index of the mold; c. Pretreatment of the mold: after preheating the mold, spray paint on the inner wall of the mold; d. With casting: after the upper and lower molds of the mold are combined, the molten metal is injected into the mold; e. Injection and cooling: The injection pressure is reasonably controlled to fill the entire mold with metal, and then the mold is cooled. Processing to make the castings rapidly formed; f. Open the mold and take out the parts: after the molding is completed, the upper and lower molds are opened, and the formed castings are dire...

Embodiment 3

[0065] A high-pressure casting process for a non-welded axial flow fan, specifically a high-pressure casting process for an impeller, including: a. Design and manufacture of a casting mold: according to the shape of the impeller, the shape of the casting mold is designed to complete the manufacture of a cone; b. The installation of the casting mold And test: put the mold into the casting machine, and test the performance index of the mold; c. Pretreatment of the mold: after preheating the mold, spray paint on the inner wall of the mold; d. With casting: after the upper and lower molds of the mold are combined, the molten metal is injected into the mold; e. Injection and cooling: The injection pressure is reasonably controlled to fill the entire mold with metal, and then the mold is cooled. processing to make the castings rapidly formed; f. Open the mold and take out the parts: after the molding is completed, the upper and lower molds are opened, and the formed castings are dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com