Cleaning process and equipment for bearing repair

A technology for cleaning equipment and bearings, which is applied in the field of cleaning technology and equipment for bearing repair, which can solve the problems of multiple equipment, complicated process, and low cleaning efficiency, and achieve the effects of simplifying cleaning steps, improving quality, and quickly cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below with reference to the accompanying drawings.

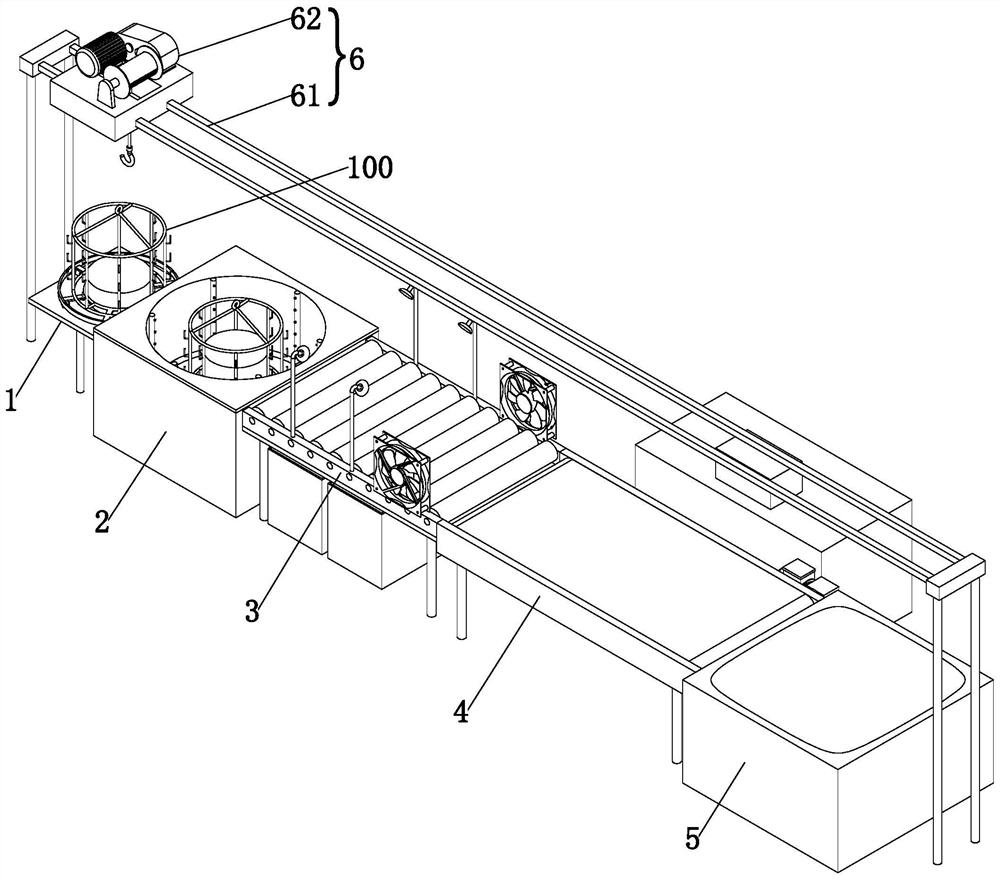

[0052] refer to figure 1 , which is a cleaning device for bearing repair disclosed in the present invention, comprising a support frame 1, a degreasing cleaning pool 2, a rust-removing cleaning table 3, a flaw detection test table 4 and a rust-proof soaking pool 5 arranged in sequence, and the cleaning equipment is arranged in a glyph production line.

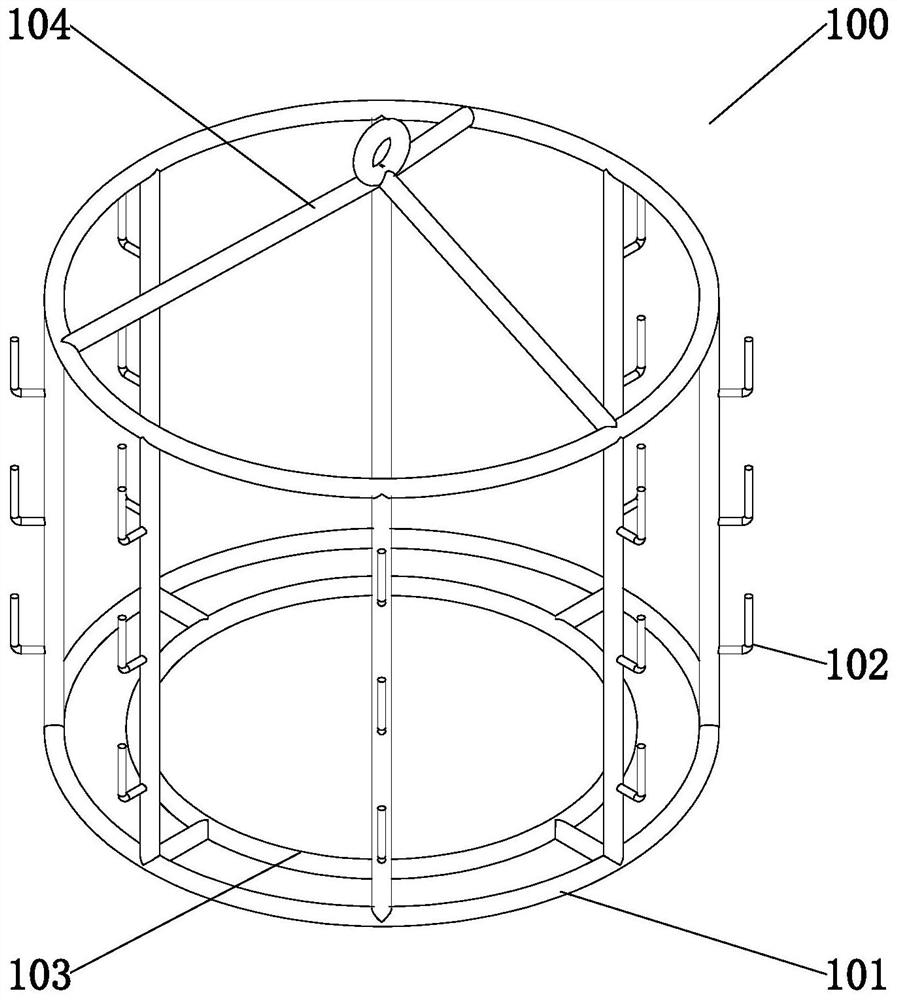

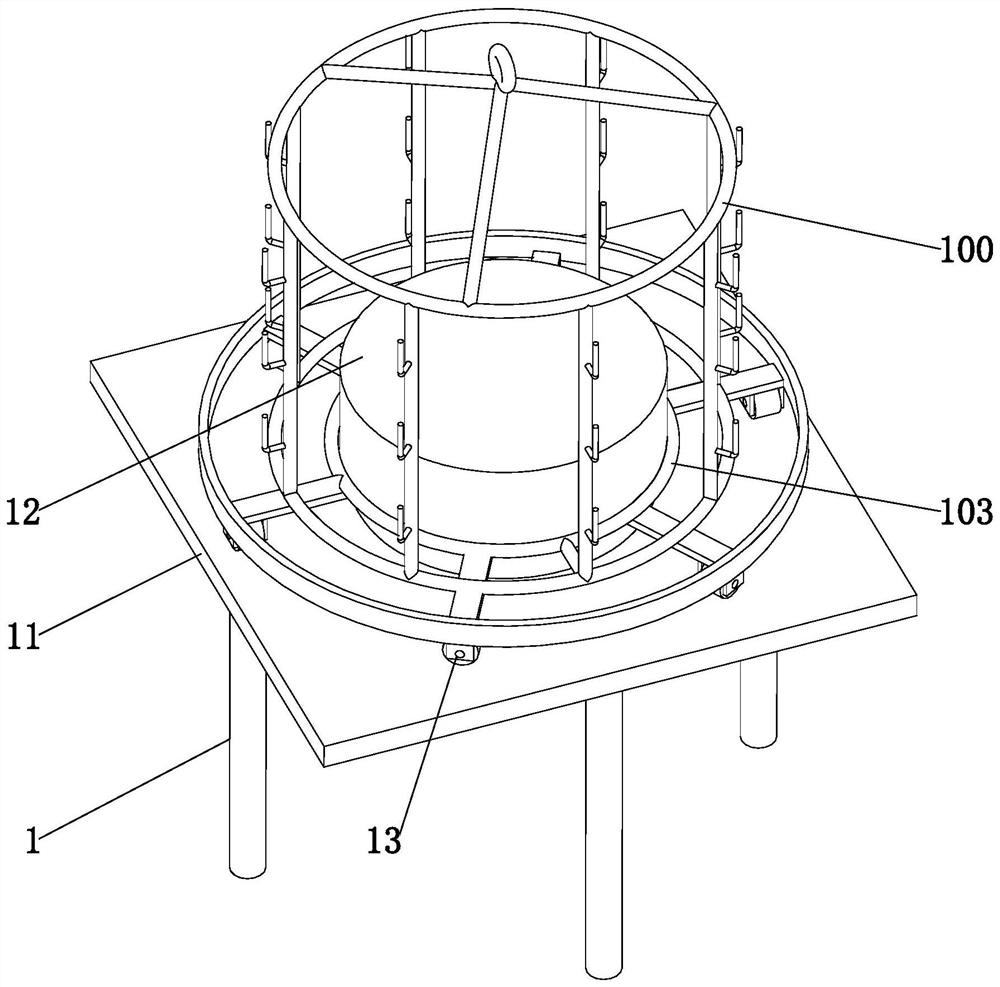

[0053] The support frame 1 is located at one end of the equipment and is used to support and place the rack 100. Before the bearing is cleaned, the bearing is disassembled into separate parts and suspended on the rack 100. The clear bearing parts in this embodiment are the inner parts of the bearing. The ring and the outer ring are hung on the periphery of the storage rack 100 , and the support frame 1 supports the storage rack 100 . The degreasing cleaning pool 2 is set close to the support frame 1, the pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com