Horizontal double-shaft reverse differential efficient stirring device for soil remediation

A horizontal dual-shaft, soil remediation technology, applied in the field of soil remediation, can solve the problems of uneven mixing, poor mixing ability, poor continuous mixing ability, etc., to ensure mixing efficiency and mixing ability, improve mixing uniformity, and improve mixing. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

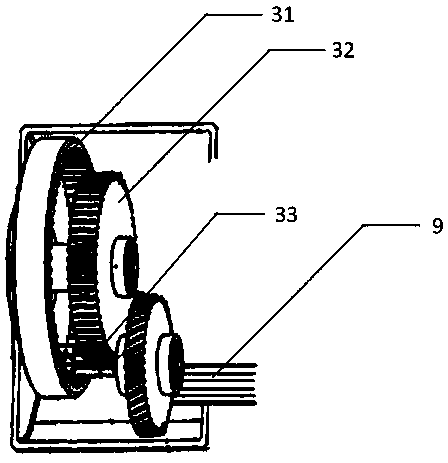

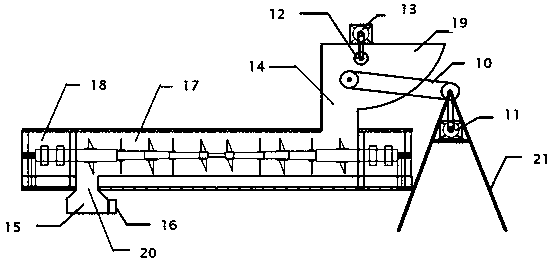

[0039] like Figure 1-4 As shown, a horizontal dual-shaft reverse differential speed high-efficiency stirring device for soil restoration, the horizontal double-shaft reverse differential speed high-efficiency stirring device for soil restoration is horizontal, the external shell module, drive module, a stirring module, a feeding module and a discharging module; the stirring module is connected to the driving module by a chain, and the stirring module is connected to the external housing module by a bearing, and both the driving module and the stirring module are two groups;

[0040] The external housing module includes a stirring bin housing 17 and a driving bin housing 18 , and the stirring bin housing 17 and the driving bin housing 18 are separated by a steel plate 2 .

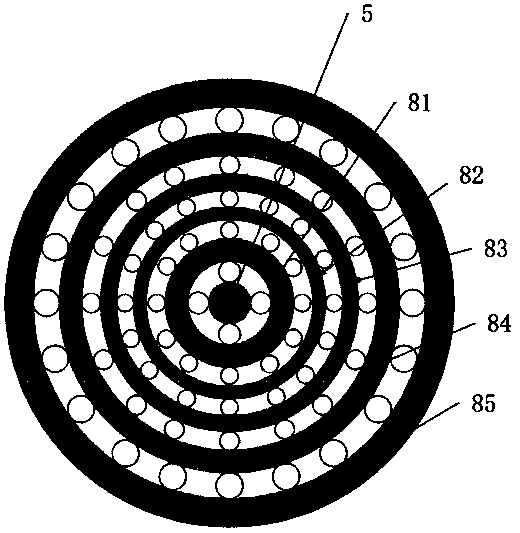

[0041] The stirring module includes a reverse stirring paddle 6, a forward propulsion paddle 7 and a concentric sleeve bearing 8. The concentric sleeve bearing takes the sleeve bearing iron core 5 as the axi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com