Sterilization and disinfection equipment for liquid organic fertilizer production

A technology of sterilization and disinfection, organic fertilizer, applied in sanitary equipment, disinfection, construction and other directions for toilets, can solve problems such as poor sterilization and disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

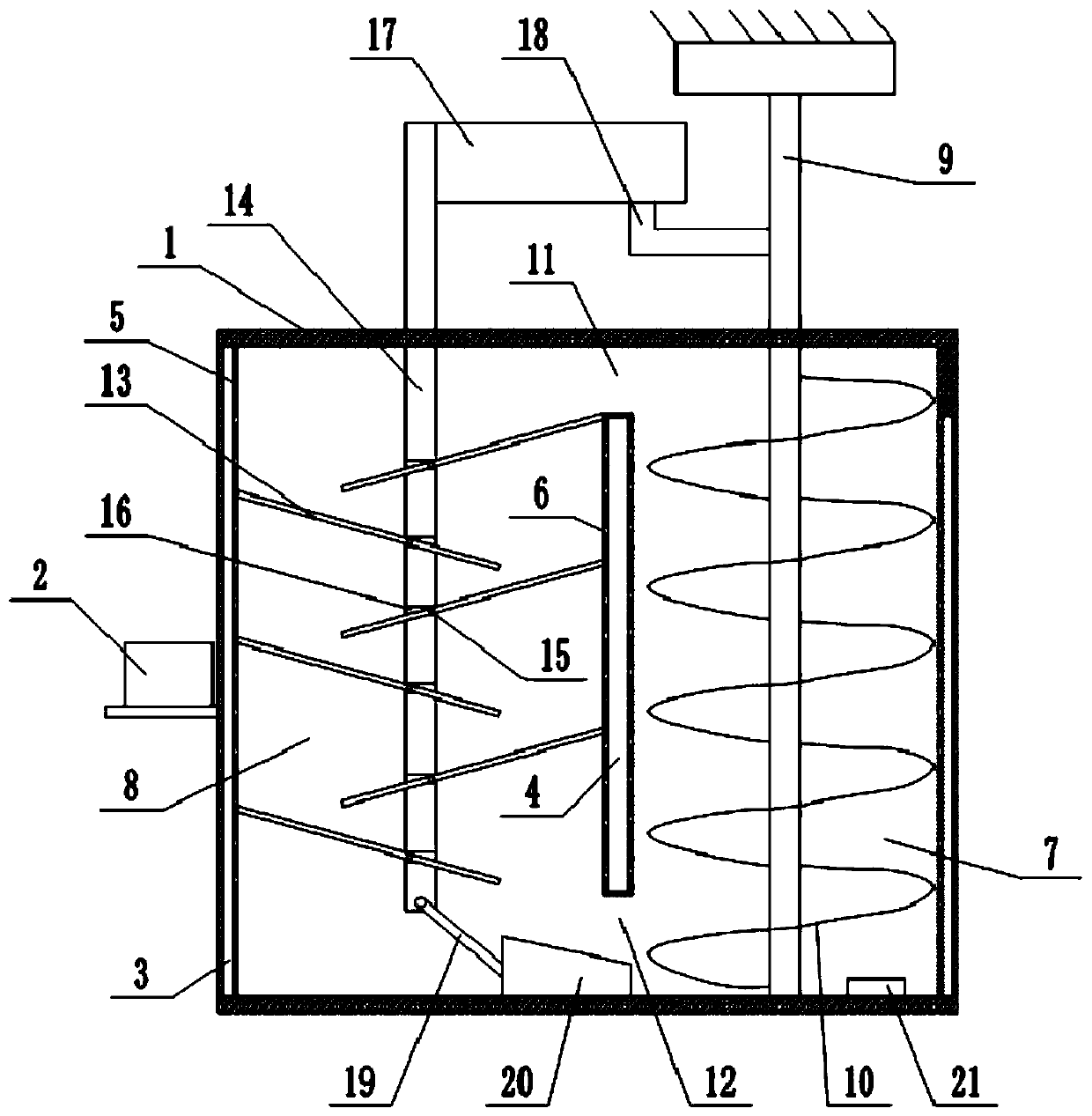

[0038] A kind of sterilization and disinfection equipment for liquid organic fertilizer production, combined with the attached figure 1As shown, it is mainly composed of a first box body 1, a screw shaft 9, a screw blade 10, a partition plate, a rolling screen 13, a swing mechanism, and a steam generating device 2. A feed inlet is installed on the top of the first box body 1 . The partition plate is vertically welded in the first box body 1, the partition plate divides the first box body 1 into the first chamber 7 and the second chamber 8, the upper end of the partition plate and the top of the first box body 1 A first output port 11 is formed between them, and a first valve is installed in the first output port 11; a material return port 12 is formed between the bottom end of the partition plate and the bottom of the first box body 1 . The first chamber 7 is rotationally connected with a screw shaft 9, and the top of the screw shaft 9 passes through the first box body 1 and ...

Embodiment 2

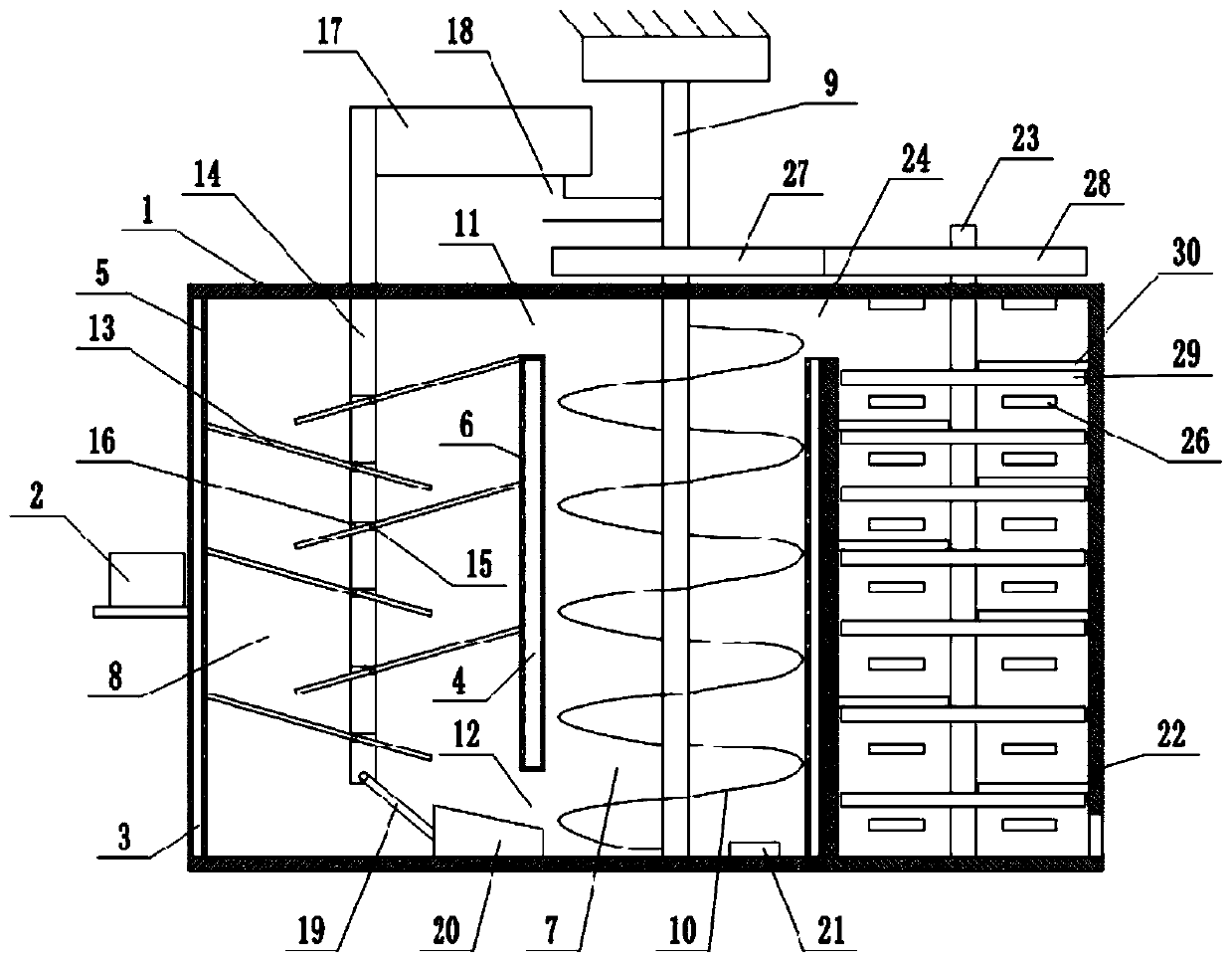

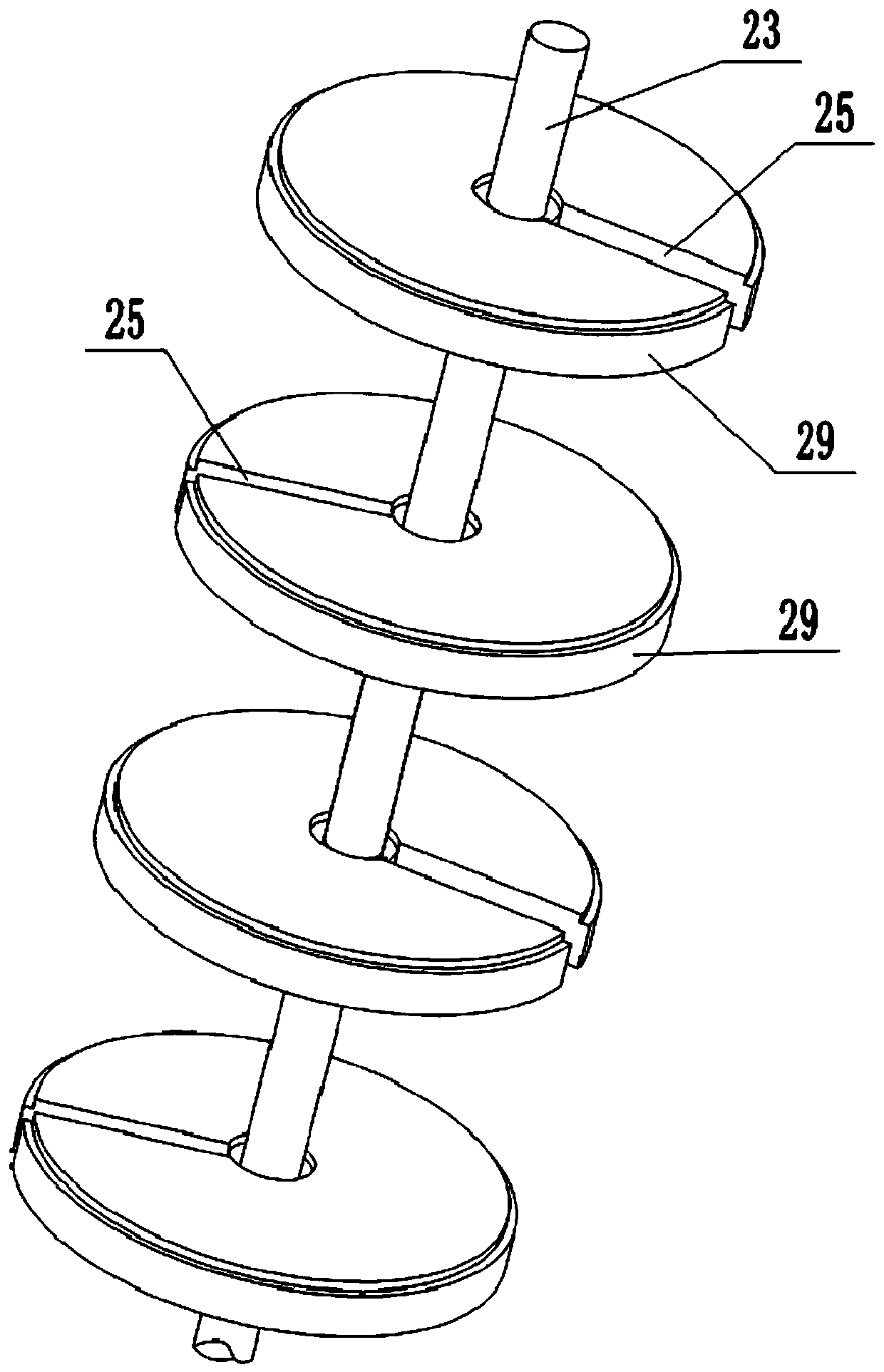

[0049] The difference between this embodiment and Embodiment 1 is that in this embodiment, a second box body 22 is also included, combined with the attached figure 2 , attached image 3 , attached Figure 4 As shown, the second box body 22 is welded on the right outer wall of the first box body 1, and the top of the right side of the first box body 1 is provided with a second output port 24, and the second output port 24 communicates with the top of the second box body 22 , and the second output port 24 is provided with a second valve. The second casing 22 is rotatably connected with a rotating shaft 23, the top of the rotating shaft 23 passes through the second casing 22 and is equipped with a driven gear 28, and the top of the screw shaft 9 passes through the first casing 1 and is equipped with a driving gear 27 , the driven gear 28 meshes with the driving gear 27 . The middle and lower parts of the rotating shaft 23 are detachably connected (specifically plugged) with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com