Solar cigar tobacco leaf airing room capable of automatically controlling temperature and humidity

A technology for cigar tobacco leaves and solar energy, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, can solve the problems of inaccurate control of temperature and humidity in the drying room of cigar and tobacco leaves, achieve automatic temperature control and humidity control, and avoid unbalanced humidity. Ensure the effect of drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

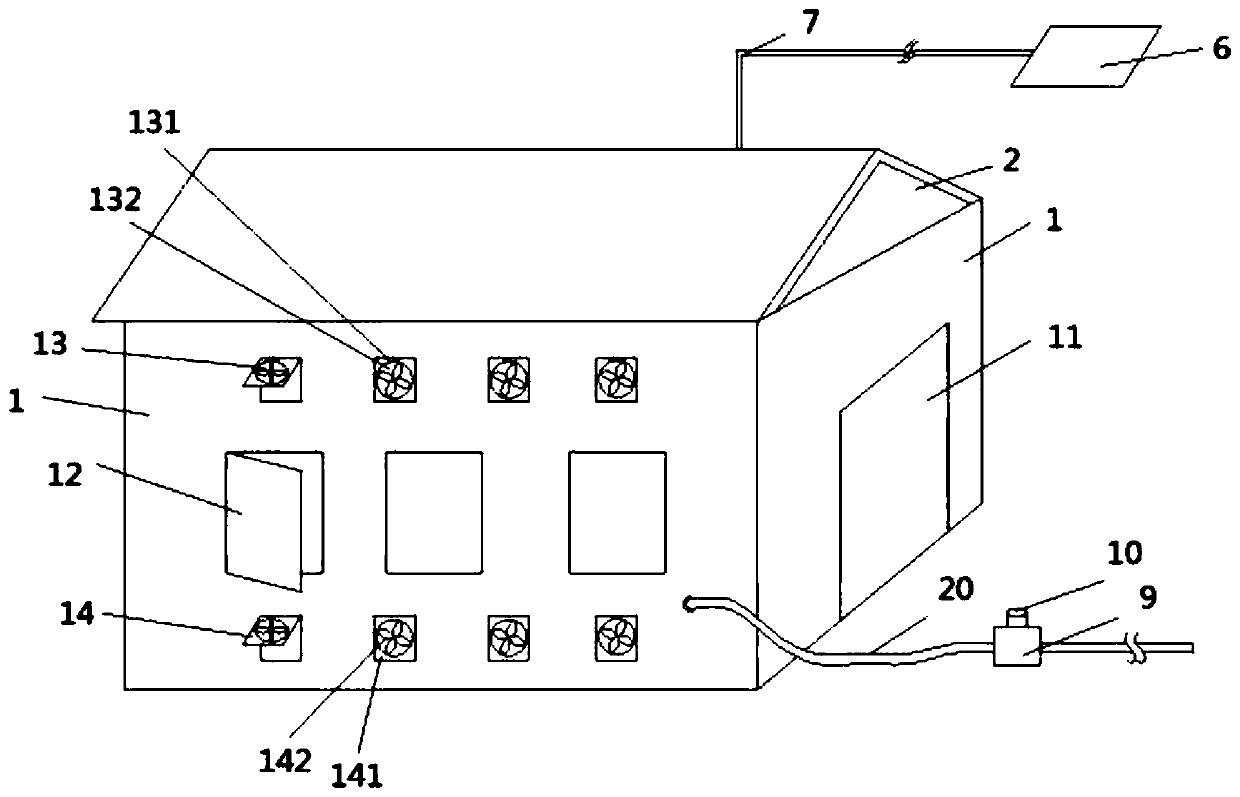

[0056] A kind of solar cigar tobacco leaf airing room with automatic temperature control and humidity control provided by the invention, such as figure 1 Shown, comprise airing room body and solar generator set 6, the output end of solar generator set 6 is connected with the cable 7 of airing room, supplies power to basic electrical equipment in the airing room;

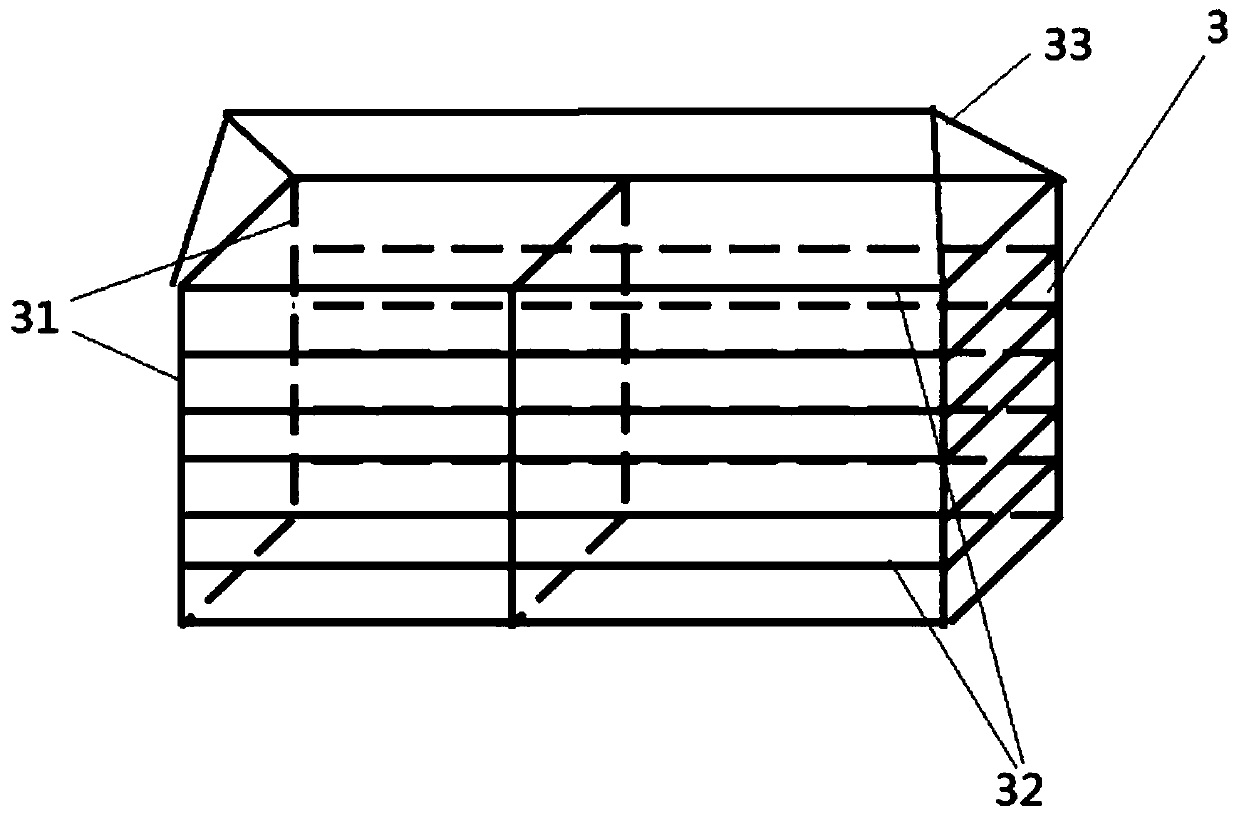

[0057] The airing room body comprises body of wall 1, roof 2 and frame 3, and frame 3 is made up of column 31, several beams 32 and herringbone roof truss 33 erected between column 31, as figure 2 As shown, the column 31, the beam 32 and the gable roof truss 33 are all wooden structures, the wall 1 is provided with doors 11 and windows 12, and the upper and lower parts of the wall 1 are respectively provided with an exhaust structure 13 and an air intake structure. 14;

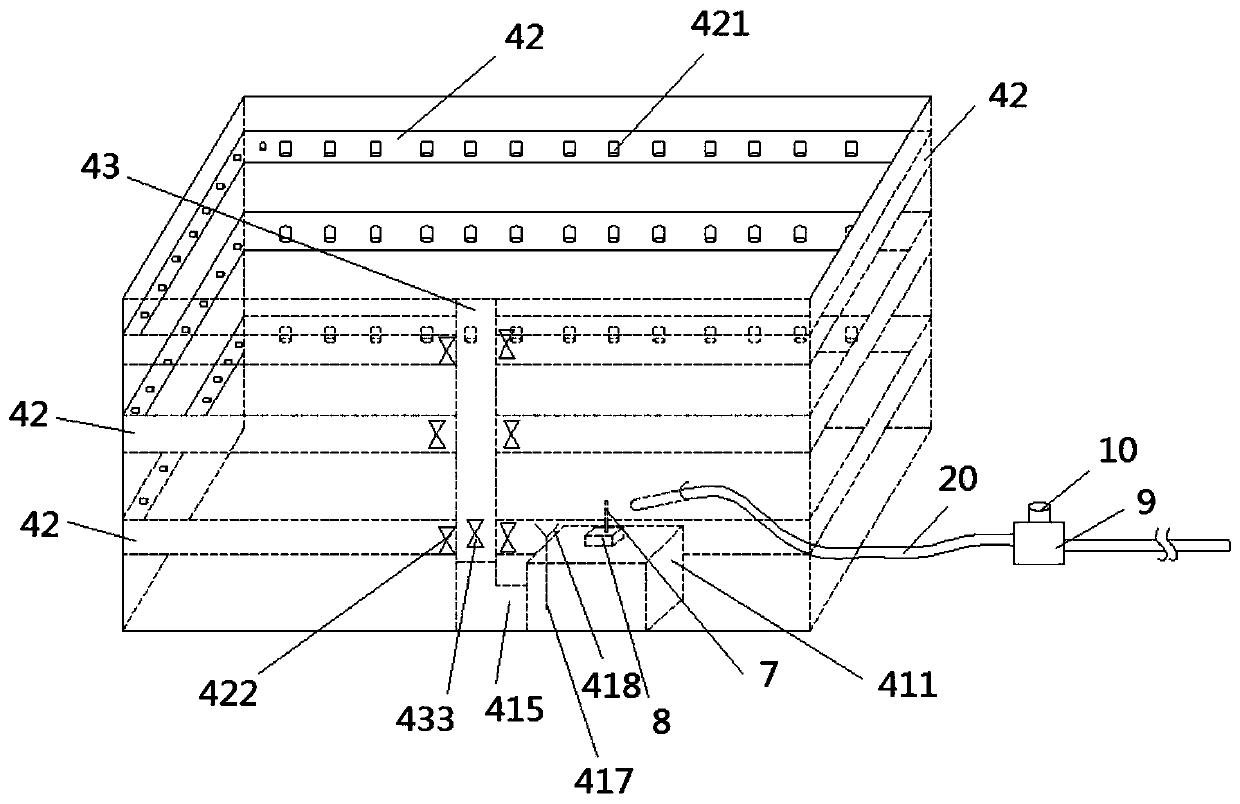

[0058] Such as image 3 As shown, the inside of the drying room body is provided with a humidifying device 4 and a cigarette drying rack 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com