Equipment for repairing broken point on surface of oil tank in oil-immersed transformer

An oil-immersed transformer, surface broken technology, applied in the field of transformers, can solve problems affecting work efficiency, troublesome handling of damaged points on the surface of the inner oil tank, etc., to ensure normal operation, keep the appearance clean, and reduce the probability of next damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

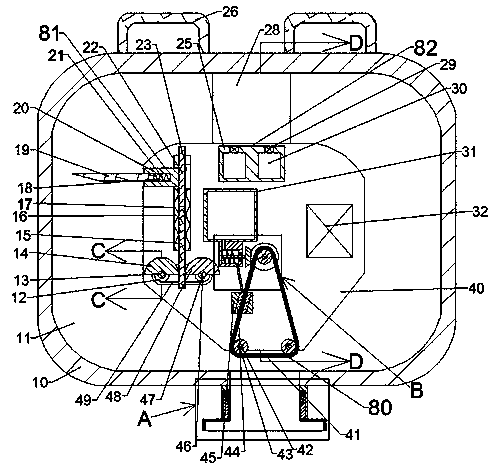

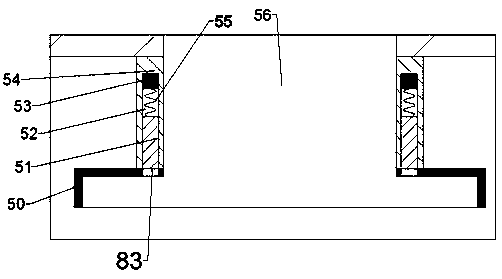

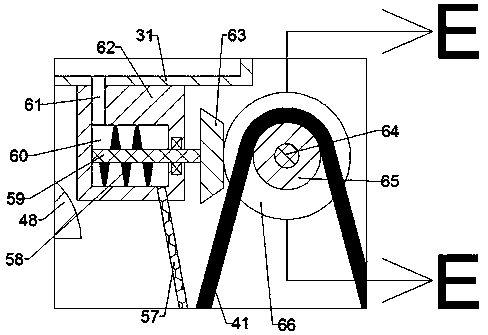

[0022] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0023] A device for repairing broken points on the surface of an oil tank in an oil-immersed transformer, as described in conjunction with accompanying drawings 1-6, includes a repair box 10, and a storage chamber 11 is provided in the repair box 10, and a support plate is provided in the storage chamber 11 40, the front end of the support plate 40 is provided with a cleaning mechanism 80, the cleaning mechanism 80 includes a power pulley 65, and the lower side of the power pulley 65 is symmetrically provided with a rotatable friction wheel 43, and the two friction wheels The wheel 43 and the power pulley 65 are frictionally driven by the cleaning belt 41, and the surface of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com