Method and device for preparing spherical metal powder through combined atomization

A metal powder and atomized powder technology, which is applied in the field of combined atomization to prepare spherical metal powder, can solve the problems of general powder production efficiency, coarse powder, and high cost of powder production, and achieve high controllability of laser energy and directionality, Wide application prospects and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

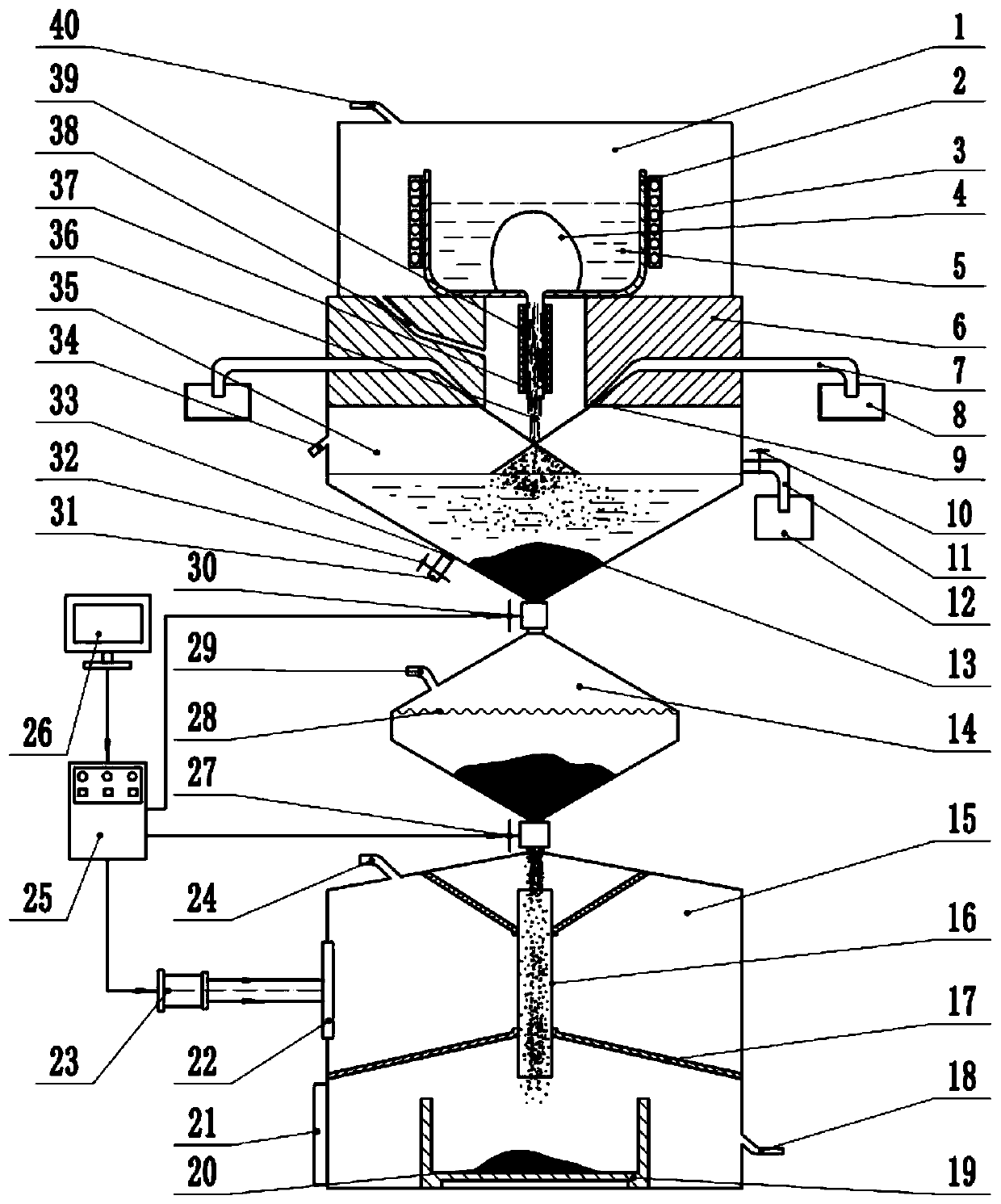

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

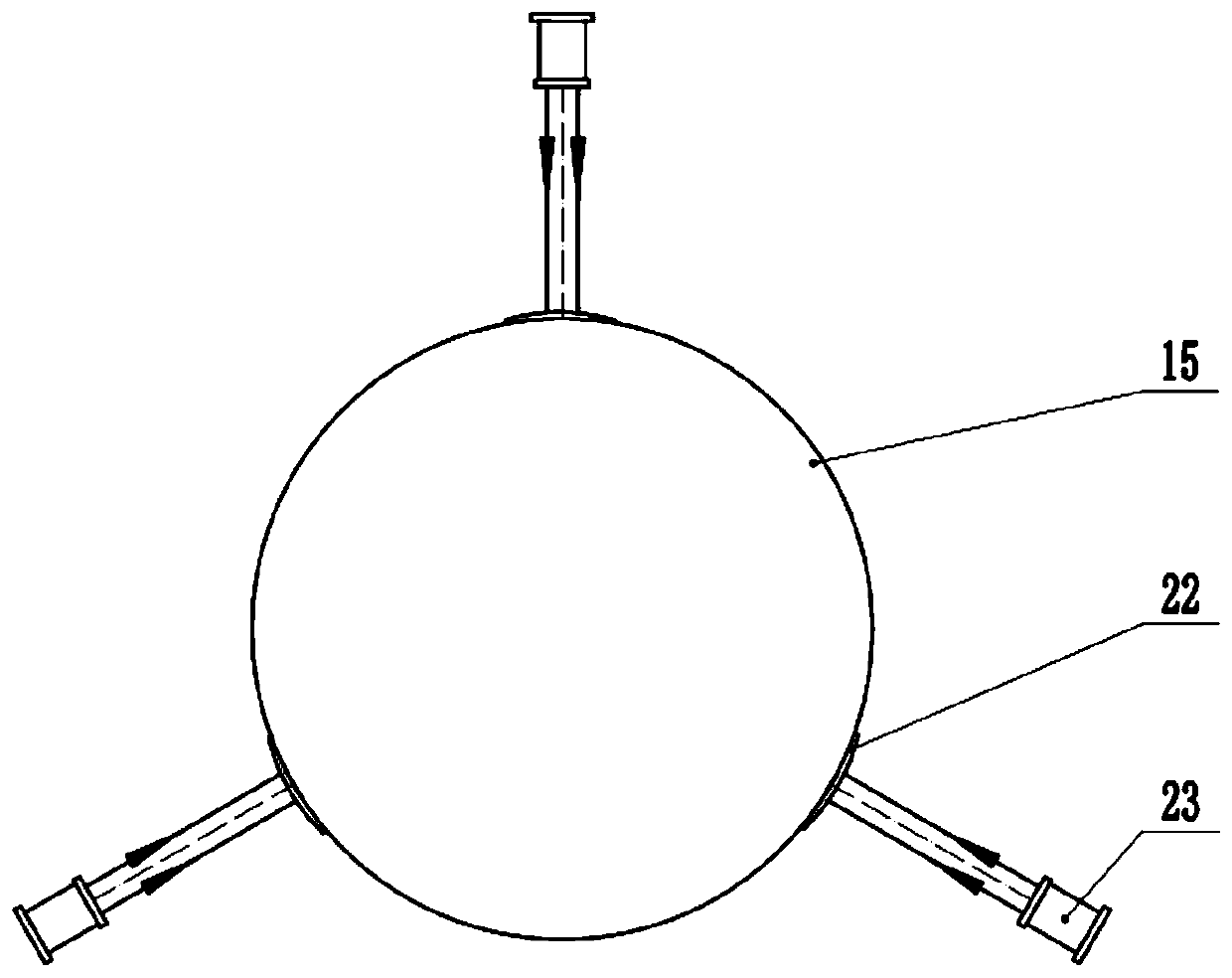

[0019] like figure 1 As shown, a combined atomization device for preparing spherical metal powder provided by the present invention includes a metal melting system, a water atomization system, a powder drying system, a laser spheroidization system, a powder collection system, a gas circulation system, Control System.

[0020]The metal melting system includes a melting chamber 1, a crucible 2, a heater 3, a metal raw material 4, and a molten metal 5 for providing molten metal 5 for water atomization; the metal raw material 4 is placed in the crucible 2 Inside; the crucible 2 is placed in the melting chamber 1, and both the crucible 2 and the bottom of the melting chamber 1 have small openings; the heater 3 is installed around the crucible 2 for heating and melting the metal raw material 4 to form a molten metal 5 ;

[0021] The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com