Preparation method of lithium-ion low-voltage power supply for commercial vehicle

A low-voltage power supply, lithium-ion battery technology, applied in the manufacture of electrolyte batteries, batteries, circuits, etc., can solve problems such as falling off, unable to start the vehicle normally, power supply cracking, etc., to prevent cracking or falling off, low internal resistance, and avoid battery effect of lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

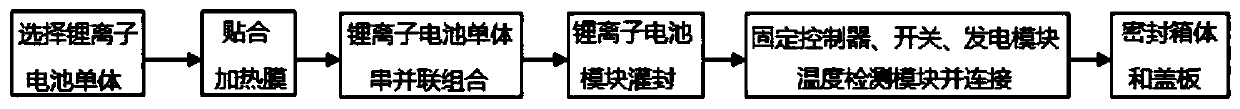

[0031] Such as figure 1 As shown, the present invention provides a method for preparing a lithium-ion low-voltage power supply for commercial vehicles, including the following steps:

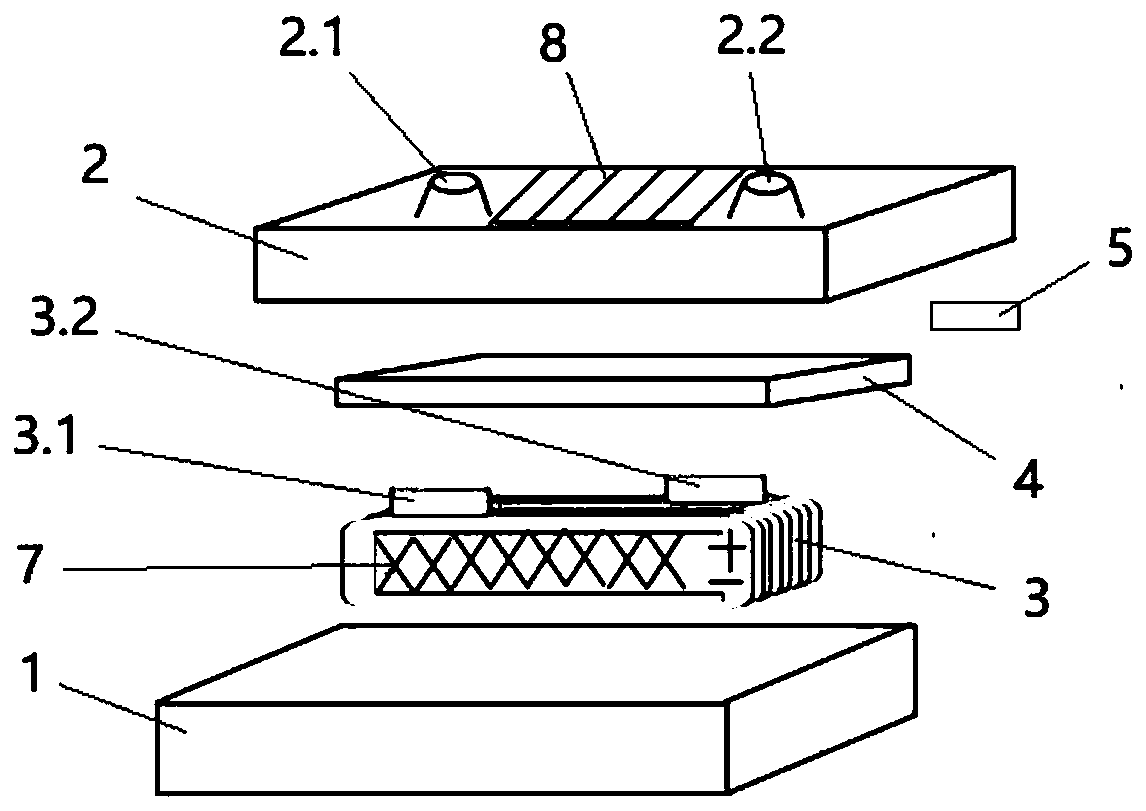

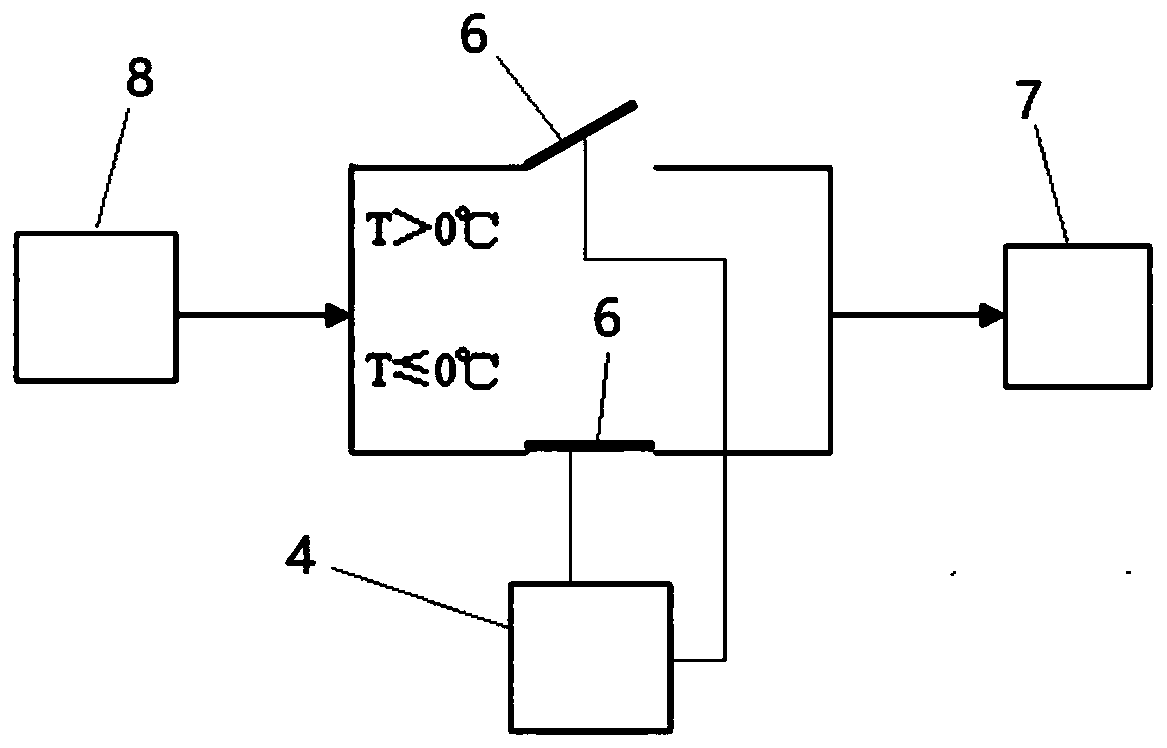

[0032] Step 1: First select 3C~15C power type lithium ion battery cells, stick the heating film 7 on the surface of the lithium ion battery cells, and the positive and negative electrodes of the heating film are on the same side of the lithium ion battery cells, which is convenient for electricity Connect; then select the metal connector of the shape required by the design, connect 2 or more lithium-ion battery cells in parallel to form a lithium-ion battery module that meets the capacity requirements; then pass 7-10 lithium-ion battery modules The metal connectors are connected in series, and the connecting wires are connected to the positive and negative electrodes of the battery in the order of "+ / - / + / -... / + / - / + / -" to form a lithium-ion battery module 3 and then fix it inside the box 1. .

[0033...

Embodiment 1

[0039] Stick the heating film on the surface of the lithium titanate battery cell, and use 4 2.4V lithium ion battery cells in parallel to form a 0.36KWh lithium ion battery module, and then use the 10 lithium ion battery modules in a straight row type The metal connectors are connected in series to form a lithium ion battery module 2, and the lithium ion battery module 2 is fixed in the box; the switch is connected in series between the heating membrane and the power generation module. Pour the prepared electronic potting glue into the box by potting method until the liquid level of the electronic potting glue is 8mm higher than the highest surface of the lithium-ion battery module, and the thickness of the surface casting is controlled at 5mm~8mm at the metal connector. The thickness is controlled between 35mm and 40mm to ensure that the lithium-ion battery module and the outer box are integrated without affecting the heat dissipation of the battery. Then put the poured box i...

Embodiment 2

[0041] Three 3.2V lithium iron phosphate battery cells are connected in parallel to form a 0.45KWh lithium ion battery module, and then 8 lithium ion battery modules are connected in series with triangular connectors to form a lithium ion battery module 2. The lithium-ion battery module 2 is fixed in the box; the prepared electronic potting glue is poured into the box by potting method until the liquid level of the electronic potting glue is 15mm higher than the highest surface of the lithium-ion battery module 2, and the thickness of the surface is poured Control the thickness between 10mm~15mm and the thickness of the metal connector between 45mm~50mm, so as to ensure that the lithium ion battery module and the box are integrated without affecting the heat dissipation of the battery; then put the poured box into a vacuum oven Vacuum, the vacuum degree is -0.08Mpa, and keep it for 5min~10min. After opening to check the thickness meets the requirements, place it in a vacuum oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com