Winding preheating and start-up method of permanent magnetic synchronous motor

A technology of permanent magnet synchronous motors and windings, which is applied in the direction of electronic commutation motor control, electrical components, starting devices, etc. It can solve the problems of starting failure, rotor vibration, uneven preheating of windings, etc., and reduce the probability of starting failure , Prevent repeated rotation and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

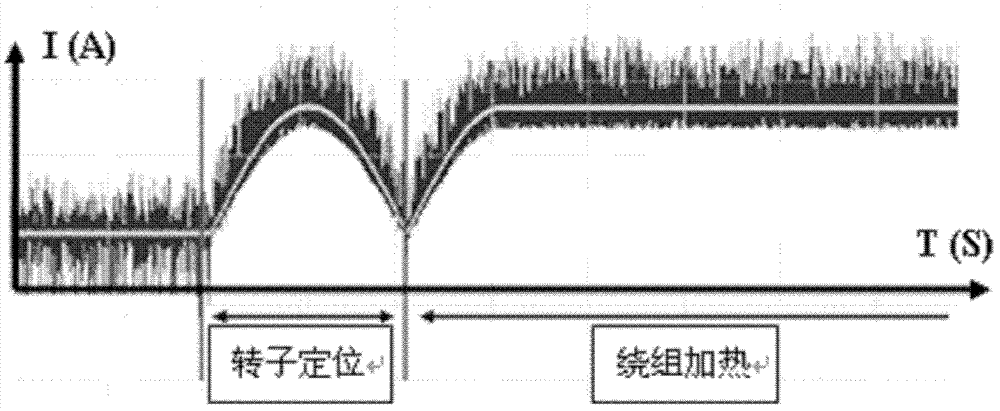

[0030] The method for preheating the windings of permanent magnet synchronous motors provided by the present invention can achieve uniform positioning and preheating of windings including but not limited to variable frequency compressors and variable frequency fans in low temperature environments without adding an external auxiliary preheating device. hot. The whole process of preheating is divided into two parts: rotor positioning and winding preheating. In order to achieve the effect of uniform preheating, this embodiment performs 3 positioning and 3 preheating of the rotor. Therefore, the direction of the designated composite magnetic field F is also 3. They are the F1 direction, the F2 direction and the F3 direction respectively, with the counterclockwise direction being positive, the synthetic magnetic field F1 direction is 0°, the synthetic magnetic fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com