Remote operation sub-box combined transformer

A combined transformer and remote operation technology, which is applied in the direction of transformer/inductor casing, transformer/inductor cooling, transformer/inductor parts, etc., can solve the problems of inconvenient maintenance and difficult construction of down-entry lines, and achieve saving Cable trench construction, small footprint and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

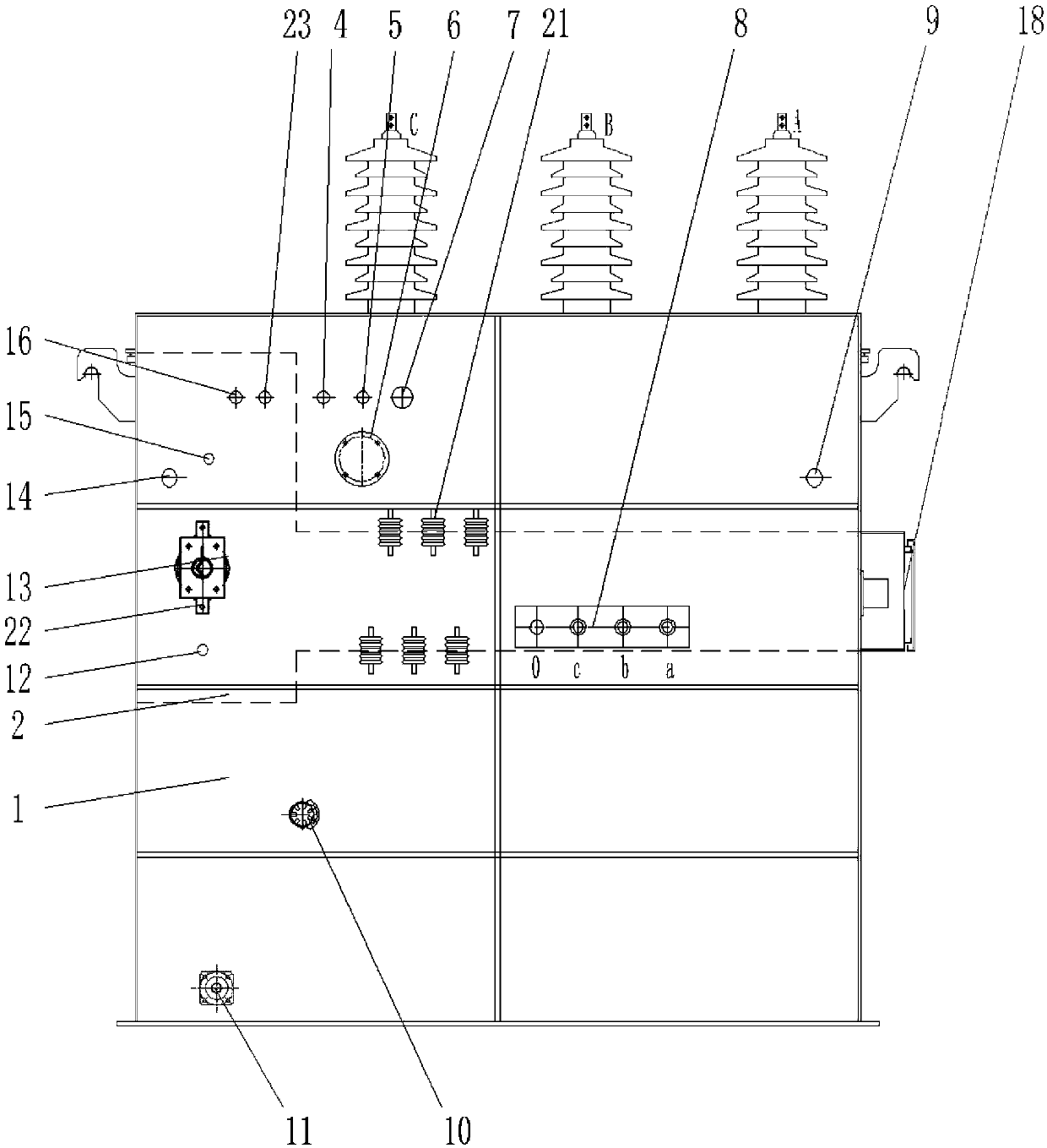

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

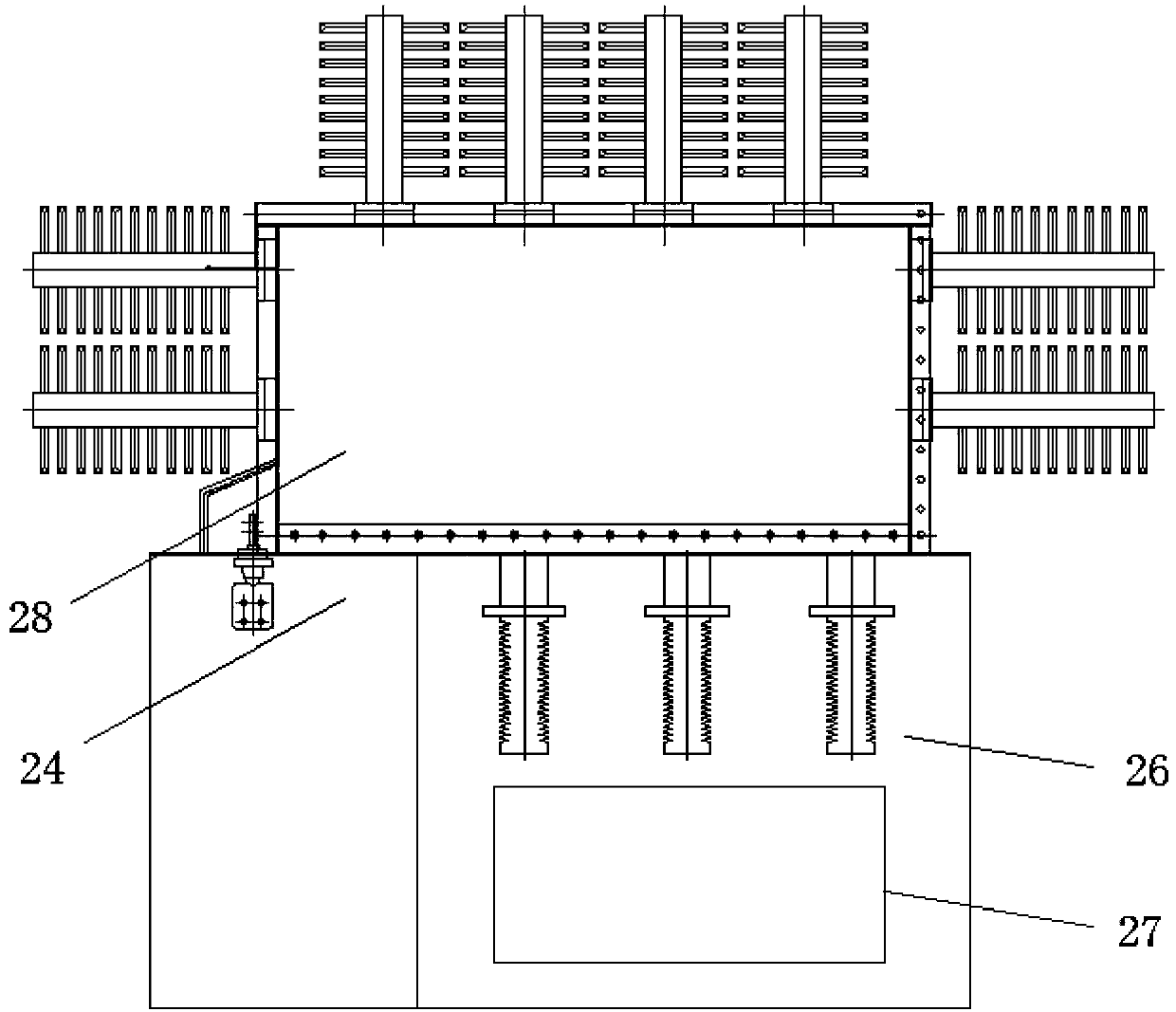

[0026] Such as Figure 2-5 As shown, the present invention is a remote operation sub-tank combined transformer, the transformer includes a main oil tank 1, an auxiliary oil tank 2 and a transformer body 3, the auxiliary oil tank 2 is used to wear the upper part of the main oil tank 1, and is a fully sealed structure between the main oil tank 1; the auxiliary oil tank 2 is provided with a fuse and a load switch 13 .

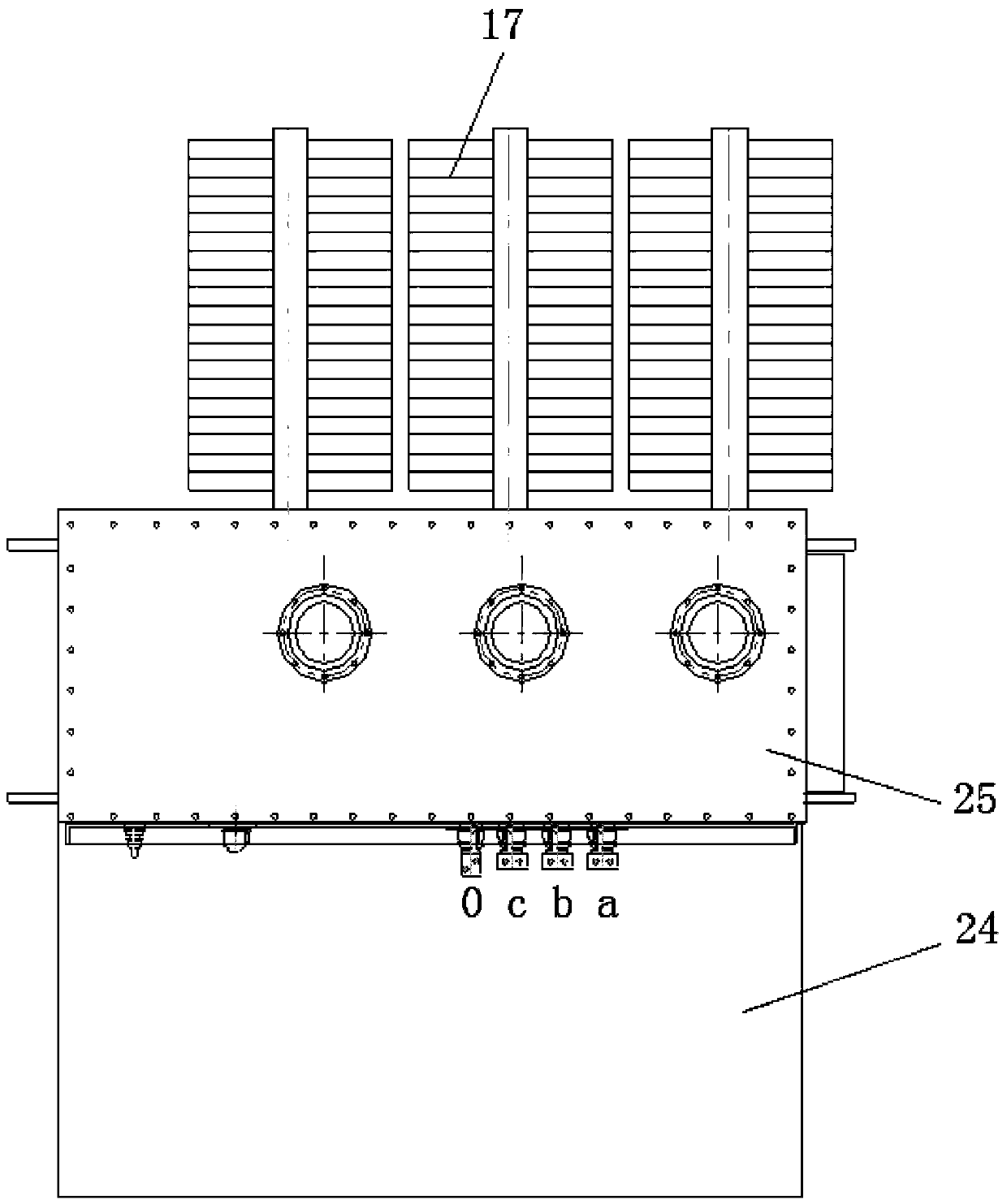

[0027] The present invention has a low-voltage chamber 24 and a transformer chamber 25, which are arranged in parallel on the front side of the main oil tank 1 of the transformer; the high-voltage bushing 20 of the transformer is directly pushed out on the top cover 19 of the main oil tank, and the high-voltage bushing 20 of the transformer is connected to the high-voltage line connection.

[0028] The tool of the present invention ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com