Double-cycloid rotor pump

A rotor pump and double pendulum technology, applied in the field of hydraulic pumps, can solve the problems of large consumables, increased specifications, volume, high operating costs, etc., and achieve the effects of cost reduction, simplified structure, and easy processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

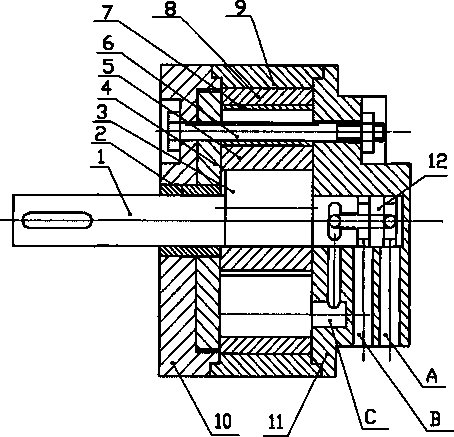

[0028] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Structure: The present invention mainly consists of transmission shaft 1, bearing 2, eccentric shaft 3, backing plate 4, inner rotor 5, column pin 6, sleeve 7, outer rotor 8, housing 9, front cover 10, rear cover 11 and flow distribution Valve 12 etc. are made up. The transmission shaft 1 is fixedly connected with the eccentric shaft 3 . The inner rotor 5, the sleeve 7 and the outer rotor 8 form several independent closed tooth chambers, and these tooth chambers communicate with the oil inlet and outlet ports A and B through the oil passage C and the distribution valve 12 respectively. The inner rotor 5 is a short-width epicycloid gear, the outer rotor 8 is a short-width hypocycloid ring gear, the axis of the inner rotor 5 coincides with the axis of the eccentric shaft 3, the axis of the outer rotor 8 coincides with the axis of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com