Gasoline engine combustion chamber and automobile

A technology for combustion chambers and gasoline engines, which is applied to combustion engines, mechanical equipment, machines/engines, etc. It can solve the problems of increased knocking tendency and achieve the effect of improving the level of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

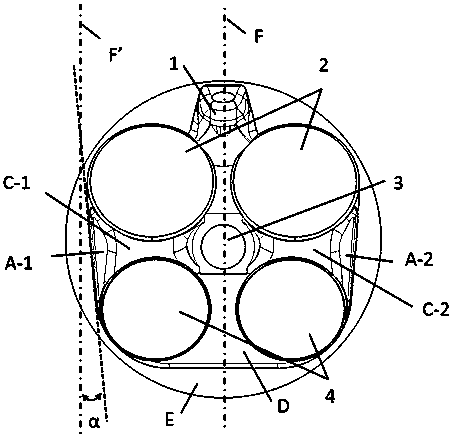

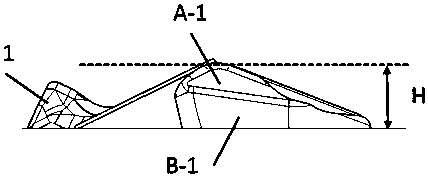

[0027] In this example, if Figure 1 to Figure 2 As shown, a combustion chamber of a gasoline engine comprises a combustion chamber body composed of a combustion chamber top surface and a combustion chamber bottom surface E, and two exhaust holes 4 are arranged on the front portion of the combustion chamber top surface, and at the rear of the combustion chamber top surface There are two air intake holes 2 corresponding to the two exhaust holes 4 on the upper part, a spark plug hole 3 is provided in the middle of the top surface of the combustion chamber, and a spark plug hole 3 is provided between the two air intake holes 2 on the top surface of the combustion chamber. A fuel injector 1 is provided at the position.

[0028] In this embodiment, the top surface of the combustion chamber is provided with an arc-shaped curved surface at the position between the exhaust hole 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com