Take-away lifting delivery system applied to dormitory building

A technology of conveying system and dormitory building, which is applied to conveyor objects, elevators in buildings, transportation and packaging, etc., can solve the problem of inconvenience of going downstairs to take take-out, achieve convenient take-out method and save delivery time. , the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

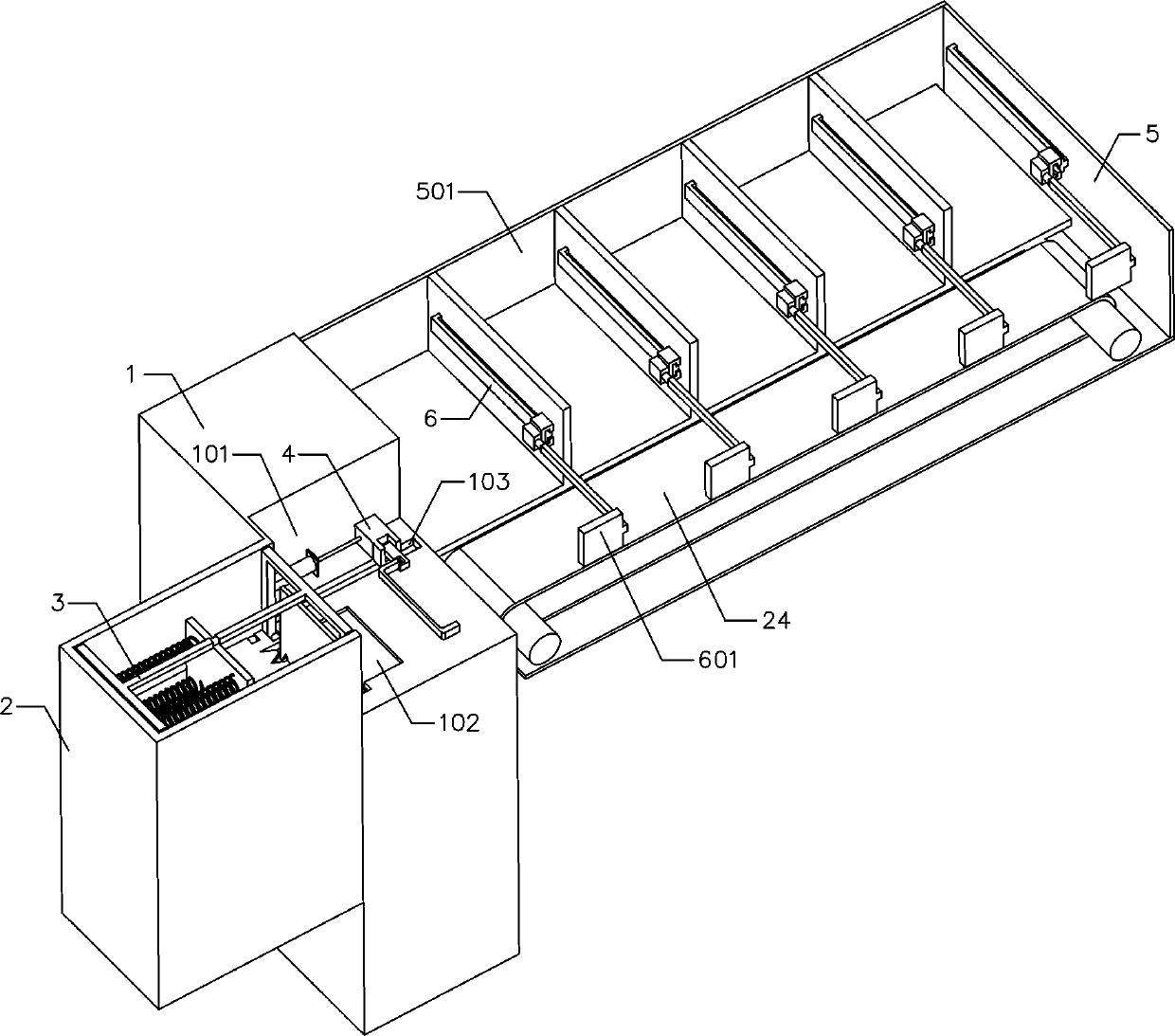

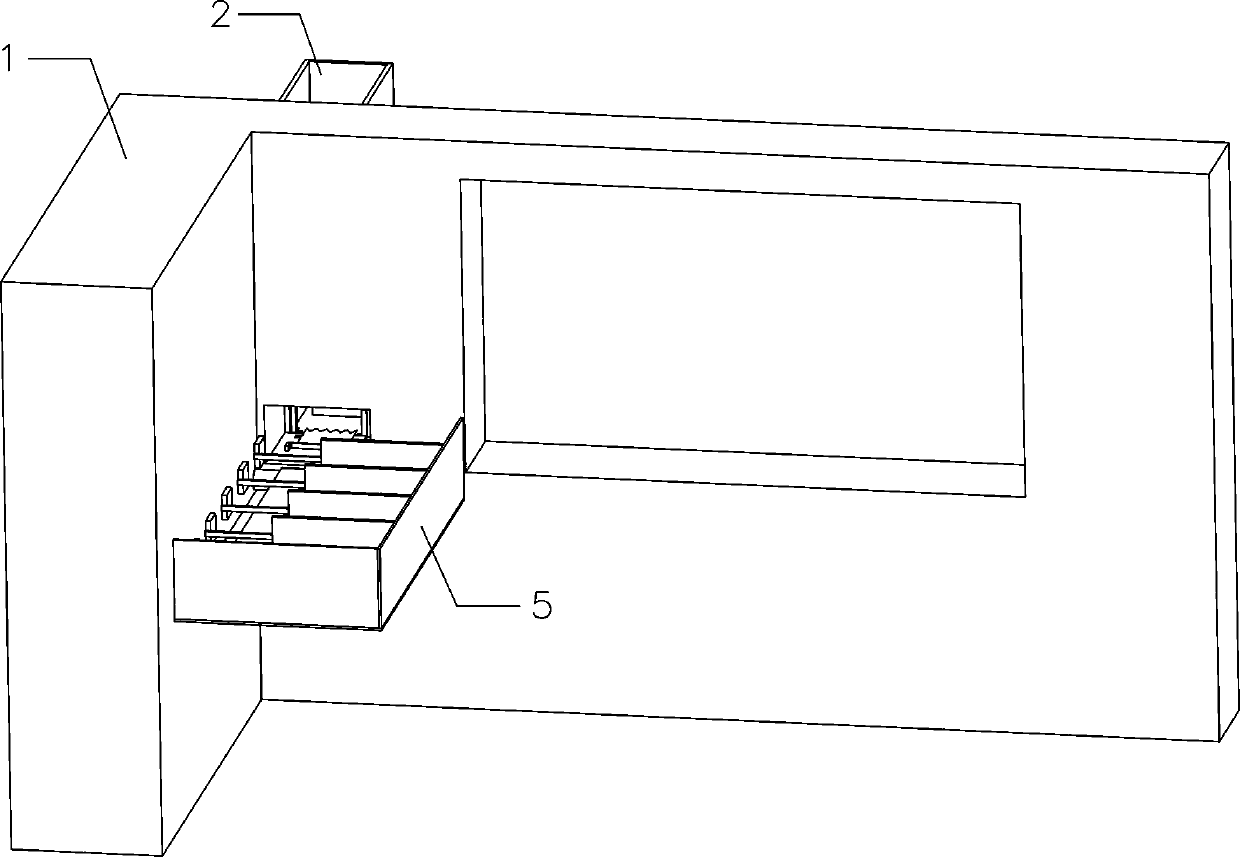

[0031] Such as figure 1 , 2 In, a take-out lifting and conveying system for a dormitory building, comprising a wall 1, the wall 1 is provided with an opening 101, the bottom of the opening 101 is provided with a push mechanism 4, and the outer wall of the wall 1 is provided with an opening 101 is located on the vertical channel 2 on the same vertical plane. The vertical channel 2 is provided with a lifting trolley 3. The wall 1 inside the opening 101 is provided with a take-out box 5, and the take-out box 5 is provided with the opening 101. The horizontal conveyor belt 24 on the same vertical surface is located on one side of the take-out box 5, and on the other side of the take-out box 5, there are multiple compartments 501, each An electric telescopic rod 6 is provided on the inner wall, and the end of the electric telescopic rod 6 is provided with a plate 601 extending above the horizontal conveyor belt 24.

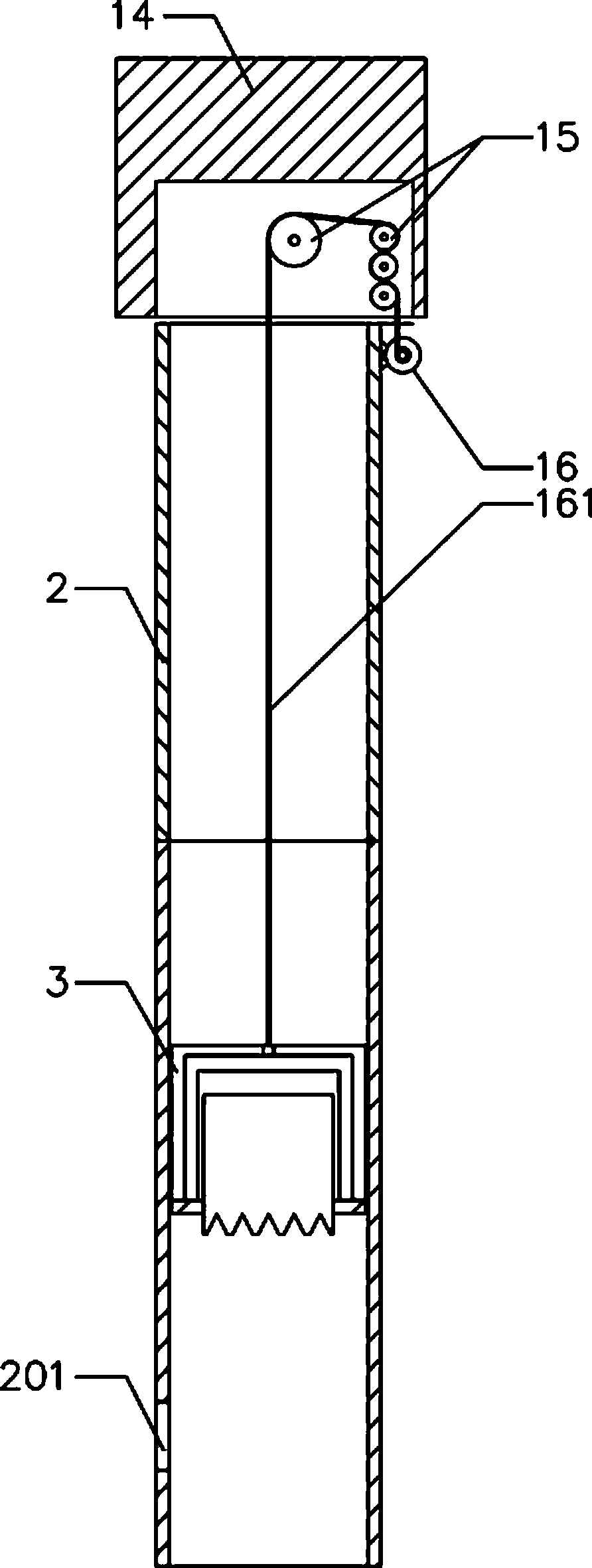

[0032] The preferred solution is image 3 , 4 Wherein, the vertical ...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 5 , 6 In the above, the lifting trolley 3 includes a bottom plate 7. Both ends of the bottom plate 7 are respectively provided with a "U"-shaped frame 8. The openings of the two "U"-shaped frames 8 face downward, and the two "U"-shaped frames 8 The horizontal sections are connected and fixed by a connecting rod 9. A fixed plate 10 is provided inside one of the "U"-shaped frames 8. The fixed plate 10 is fixedly arranged on the bottom plate 7, and the bottom plate 7 is provided with a horizontal spring group 1001. One end of 1001 is fixed on the bottom plate 7, and the other end is connected and fixed to a movable plate 11 vertically arranged above the bottom plate 7 and capable of horizontal movement;

[0035] A baffle 13 is provided in the "U"-shaped frame 8 at one end of the bottom plate 7 away from the fixed plate 10, and the lower end of the baffle 13 and the lower ends of both sides of the "U"-shaped frame 8 are connected by co...

Embodiment 3

[0038] On the basis of Example 1, such as figure 1 , 2 In the bottom surface of the opening 101 is provided with a trough 102, a horizontal top plate 17 capable of moving horizontally is provided in the trough 102, a rack 171 is provided on one side of the horizontal top plate 17, and a tooth The gear 231 meshed with the bar 171 is driven by a second motor 23 arranged in the wall 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com