Forming mechanism of brick press

A forming mechanism and brick press technology, applied in ceramic forming machines, forming press heads, unloading devices, etc., can solve the problems of single function, low quality of finished bricks, brick pre-pressing and stripping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

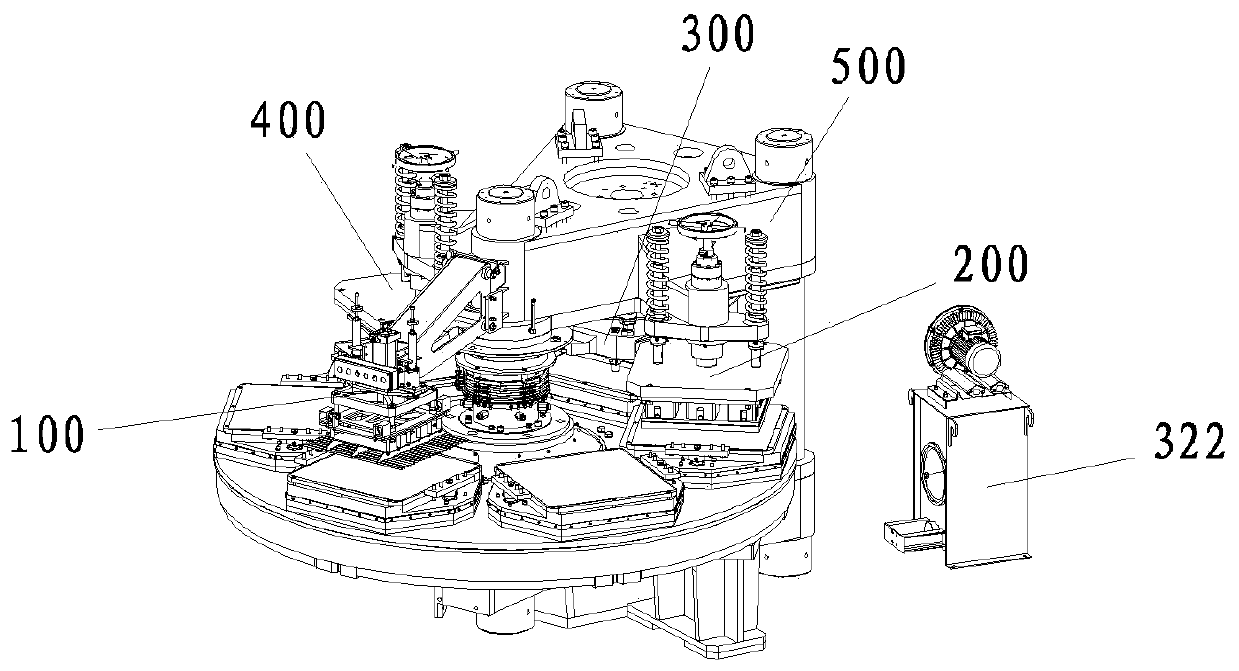

[0096] Such as Figure 1-21 As shown, a forming mechanism of a brick press includes a spreading mechanism 100 for spreading raw materials, a pre-pressing mechanism 200 for pre-pressing raw materials, and a main pressing mechanism 300 for main pressing raw materials. The demoulding mechanism 400 for brick demoulding, and the main bearing frame 500 carrying the spreading mechanism 100 , the pre-pressing mechanism 200 , the main pressing mechanism 300 and the demoulding mechanism 400 .

[0097] After adopting the above structure, the forming mechanism of the present invention has various brick-making processing mechanisms to process the raw materials in the brick forming mold. The brick forming mold can be conveyed by the mold conveying device, so that the brick forming mold passes through the spreading mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com