A composite flexible bending forming method for pipes

A technology for bending and forming of pipes, applied in the field of composite flexible bending and forming of pipes, can solve the problems such as the optimization method of bending forming process of complex metal components, and achieve the effect of important engineering application value, high production efficiency and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

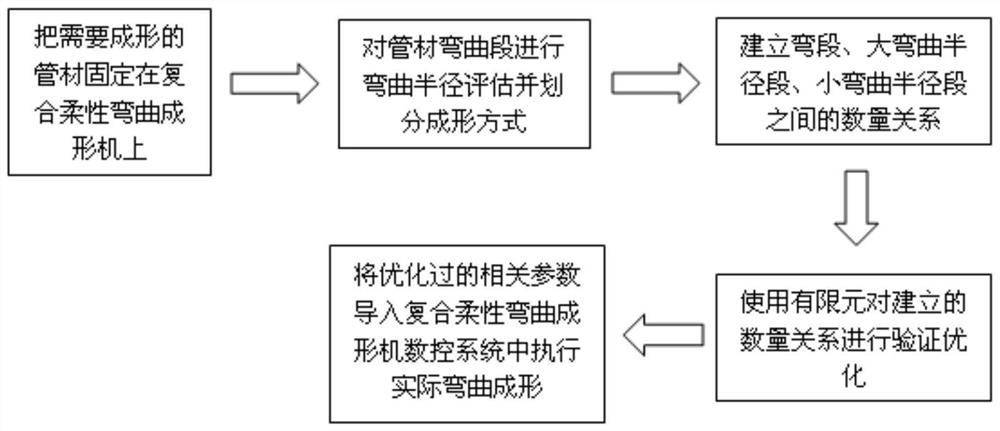

[0026] The first step is to segment the 3D geometric model of the complex shape elbow with a length of 2000mm;

[0027] The second step is to evaluate the bending radius of the segments in the first step, and divide the bending radius of the pipe into a smaller bending radius and a larger bending radius. There are 5 straight sections, 3 sections are formed straight sections, and 2 sections are tails. Push the end into the straight section. Two curved sections with large variable curvature bending radius formed by three-dimensional free bending technology. There are 2 sections of curved sections with small bending radius formed by numerical control bending technology.

[0028] The third step is to establish the relationship between the geometric shape parameters of the straight section, the large bending radius section, and the small bending radius section, such as the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com