Automatic screening device for aggregate of cementing dam building material

An automatic sieving and cementing technology, which is applied in the fields of filtration, solid separation, and non-rotational vibration suppression, can solve the problems of reduced service life, low work efficiency, and incomplete aggregate screening, so as to reduce production costs and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

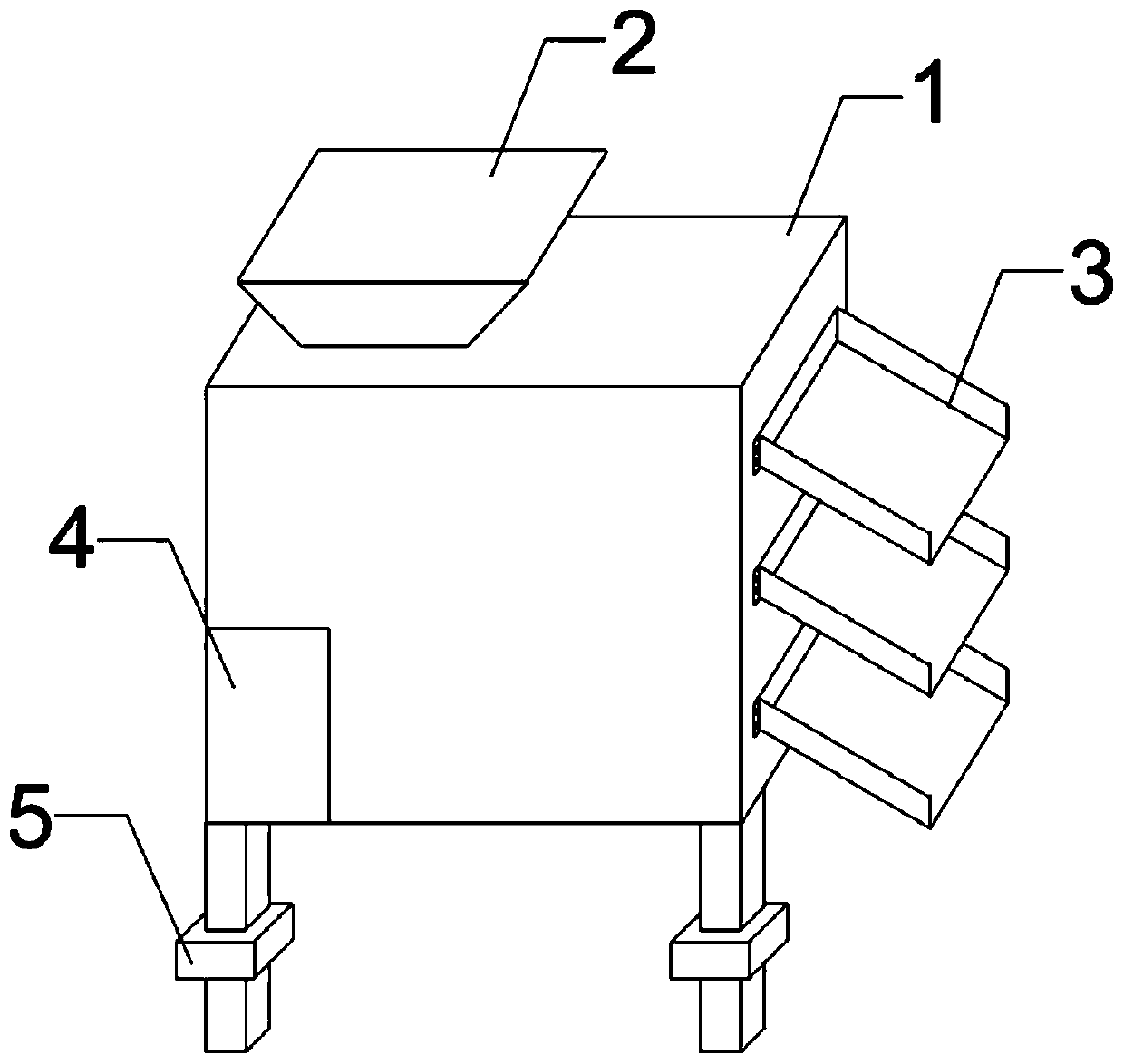

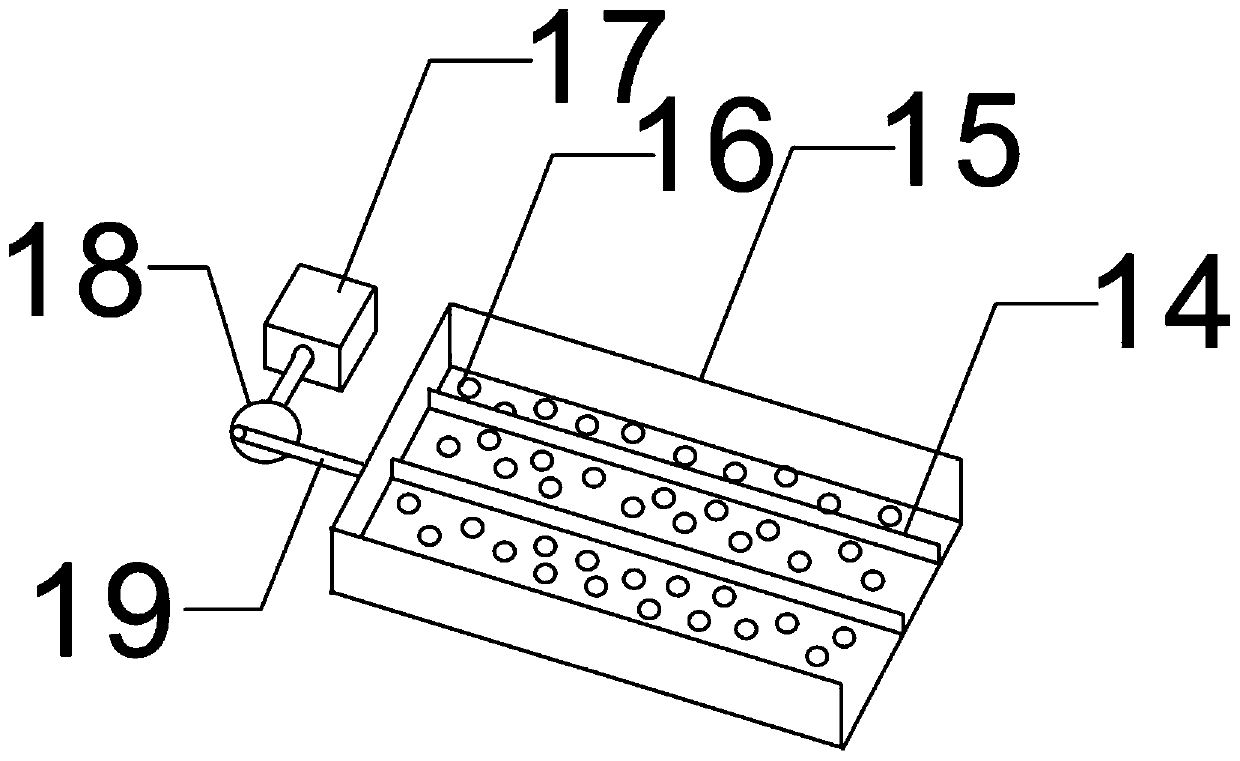

[0034] In one embodiment of the present invention, as Figure 1-6As shown, there is provided a cemented dam dam-building material aggregate automatic screening device, including a housing 1, a feeding hopper 2, several detachable feeding troughs 3 and a support frame, and the feeding hopper 2 is arranged above the housing 1 On one side, the feed trough 3 is set on the side of the shell 1 away from the feed hopper 2, the support frame is set under the shell 1, and the control device 4 is also set on the shell 1, the control device 4 is Omron CP1H-X40DT-D type PLC controller; several detachable sieve plates are arranged obliquely in the shell 1, and several sieve holes 16 with the same diameter are arranged on the sieve plates. The sieve plate 8 and the third sieve plate 9, the upper side of the sieve plate is set under the feed hopper 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com